Reaction cup feeding mechanism

A technology of reaction cup and main stirring, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of chain drive drive mechanism occupying a large space, difficult to achieve large-scale supply in a short time, and unfavorable for user operation. , to achieve the effect of good promotion and application prospects, simple structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0028] It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

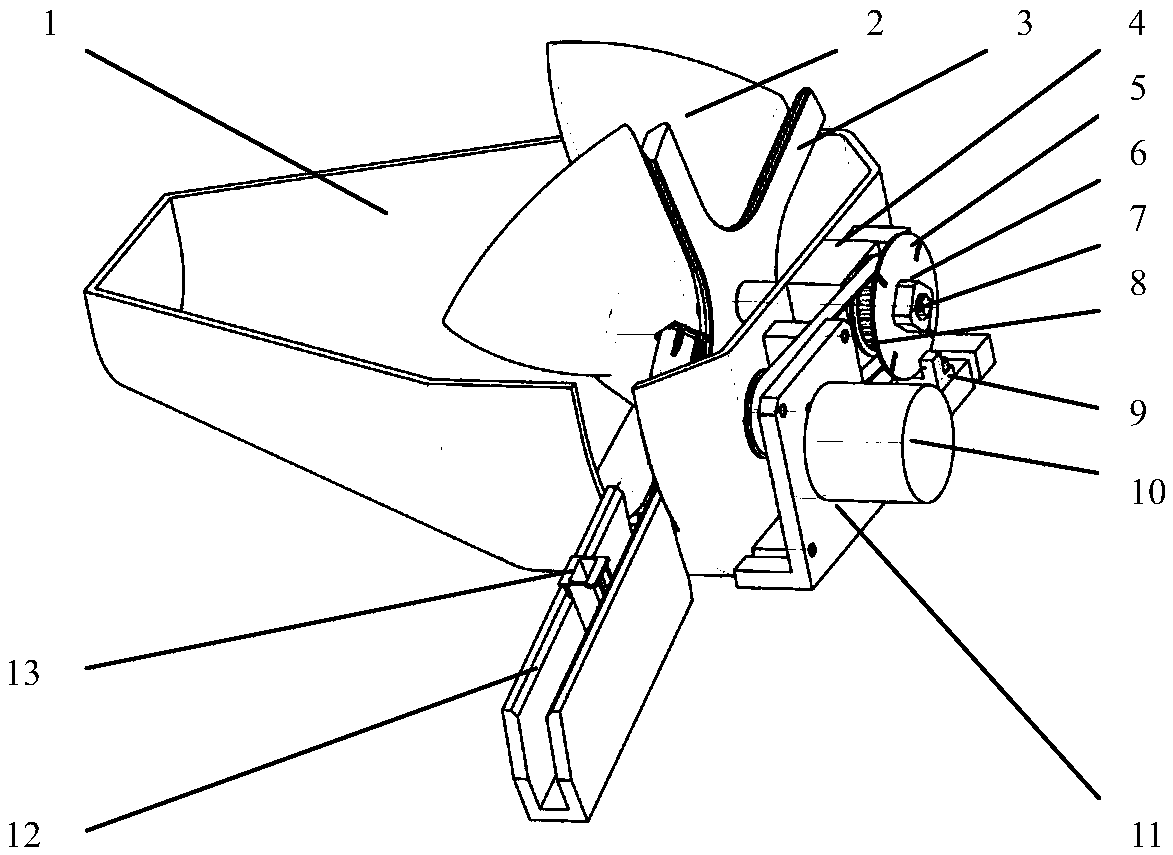

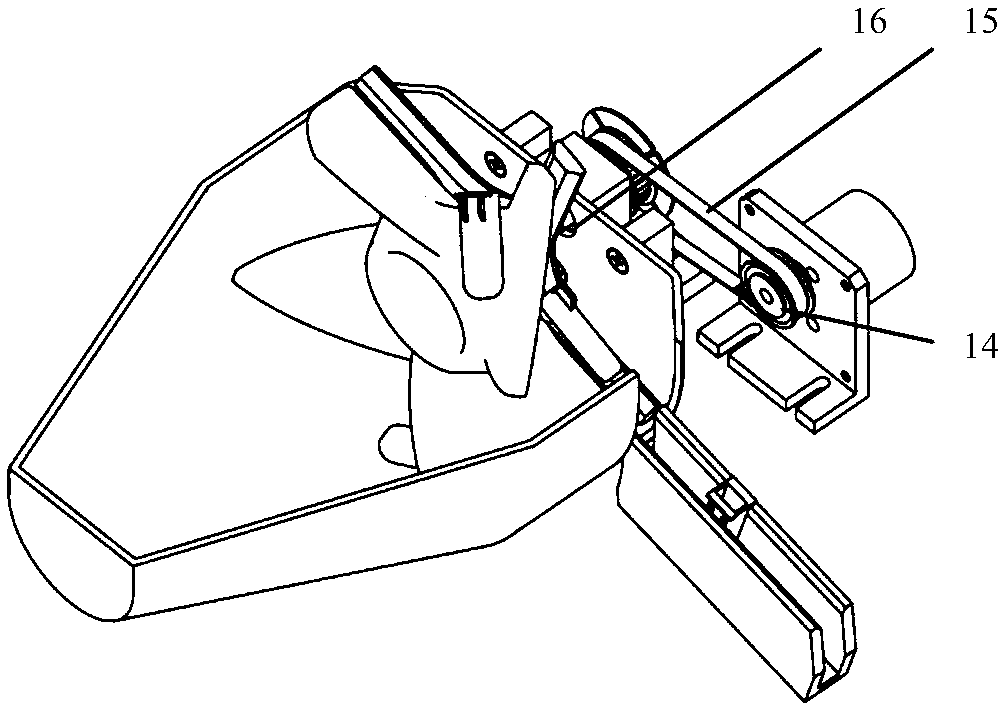

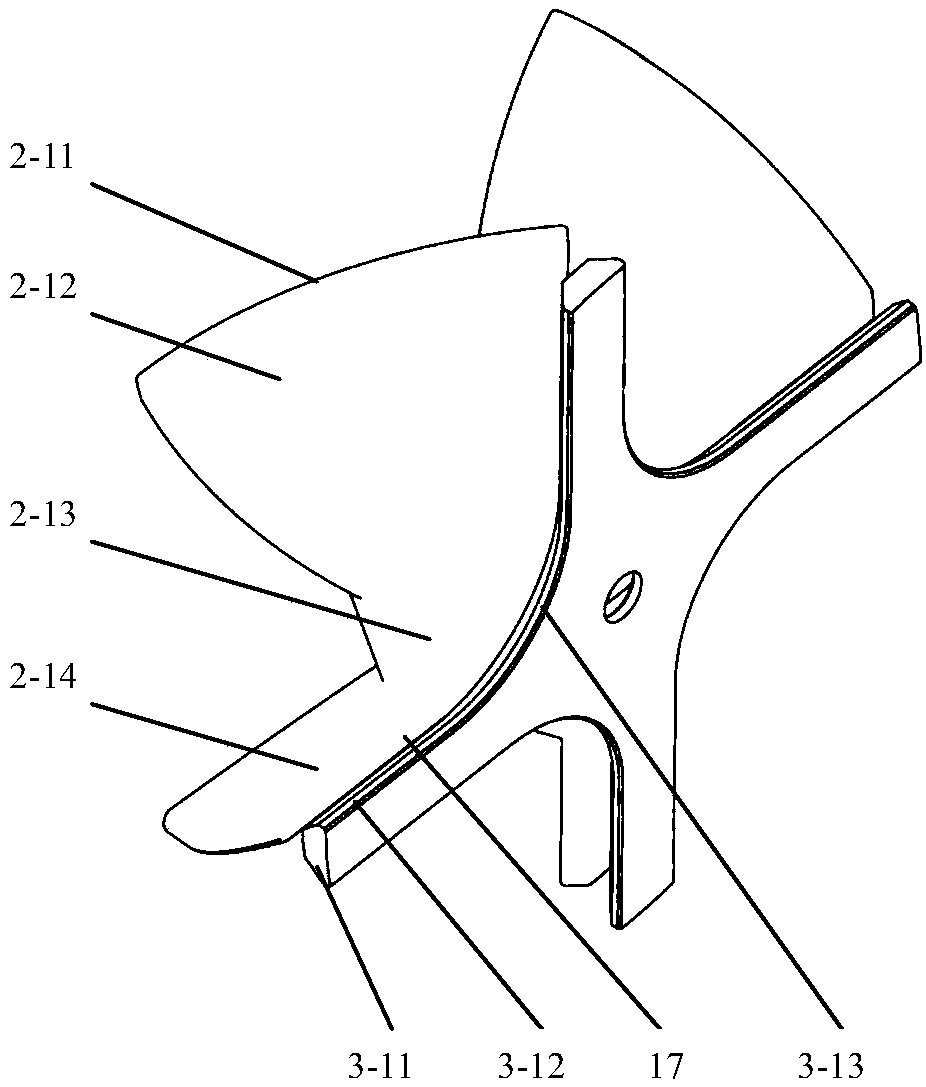

[0029] Such as Figure 1-8 As shown, a cuvette 13 feeding mechanism in this embodiment includes a rotary bin 1, a main stirring wheel 2 arranged in the rotary bin 1, a main stirring wheel 2 arranged in the rotary bin 1 and connected to one side of the main stirring wheel Auxiliary stirring wheel 3, a driving device arranged on the revolving chamber 1 and drivingly connected to the other side of the auxiliary agitating wheel 3, cuvette outlet 1-13 provided on the side of revolving chamber 1 and cuvette outlet 1-13 The ramp slideway 12 on the top; a chute 17 for accommodating the reaction cup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com