Liquid raw material generation device used for three-dimensional printing and control method of liquid raw material generation device

A liquid raw material, three-dimensional printing technology, applied in the field of additive manufacturing, can solve the problems of liquid metal monitoring difficulties, continuous addition of solid raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

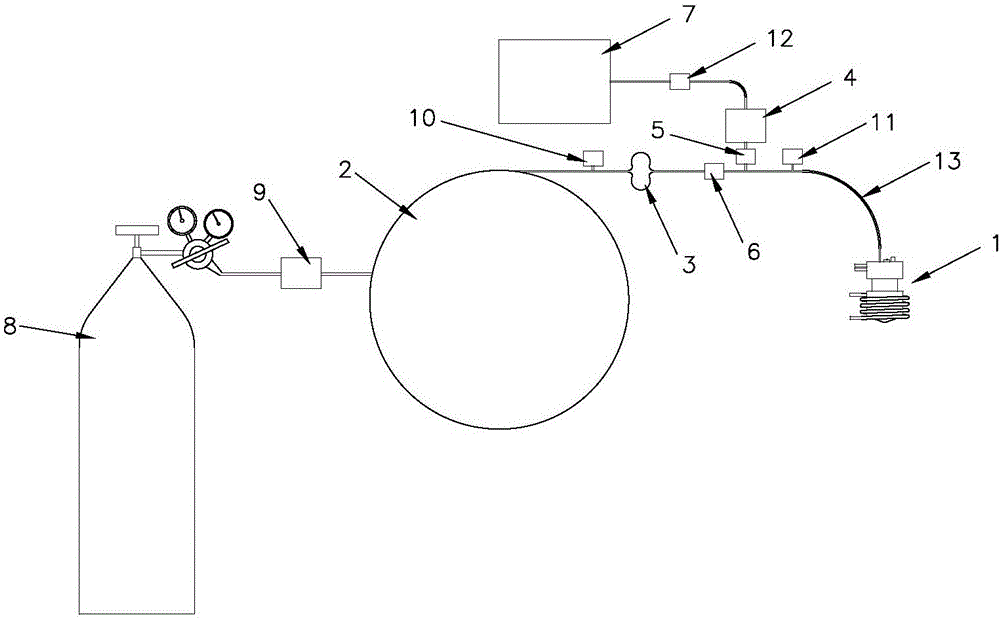

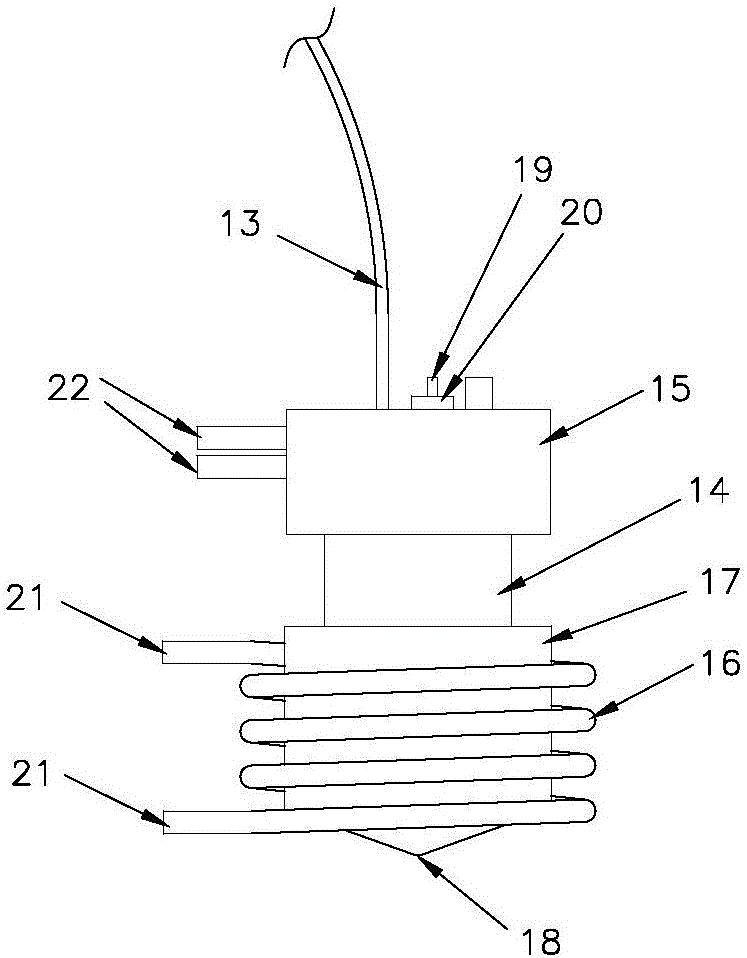

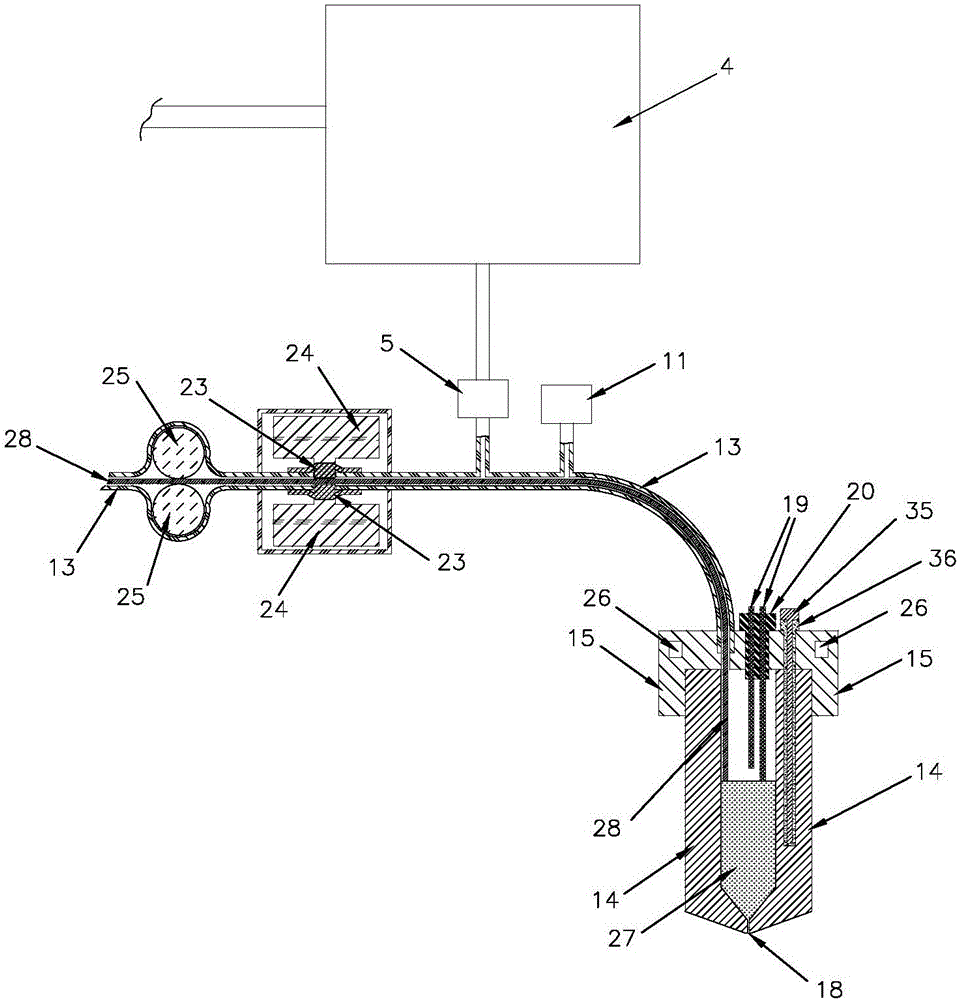

[0064] Such as Figure 1 to Figure 5 The first specific embodiment of a liquid raw material generating device for three-dimensional printing shown in the present invention: a liquid raw material generating device for three-dimensional printing, which heats and melts the solid raw material in the container to obtain the liquid raw material, By adjusting the pressure in the container to control the output state of the liquid raw material from the container; it is mainly composed of the heating unit 1 used to generate the liquid raw material, and the opening and closing device used to control the internal space of the heating unit 1 to communicate with the outside atmosphere or with the negative pressure device 15. Switching device for controlling the entry of solid raw materials into the inner space of heating unit 1 26. Air pressure sensing device (including air pressure sensor 10, air pressure sensor 2 11, air pressure sensor 3 12), liquid level sensing circuit 19, The tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com