Polybutadiene and epoxidized polybutadiene composition, adhesive, glued metal foil, prepreg, laminated board and preparation method

A technology of prepreg and polybutadiene resin, which is applied in the direction of conjugated diene adhesives, adhesives, metal layered products, etc., and can solve the problem of limited peel strength, failure to meet low dielectric loss, and easy surface of glued copper foil. Damage and other problems, to achieve the effect of improved peel strength, low dielectric loss, and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

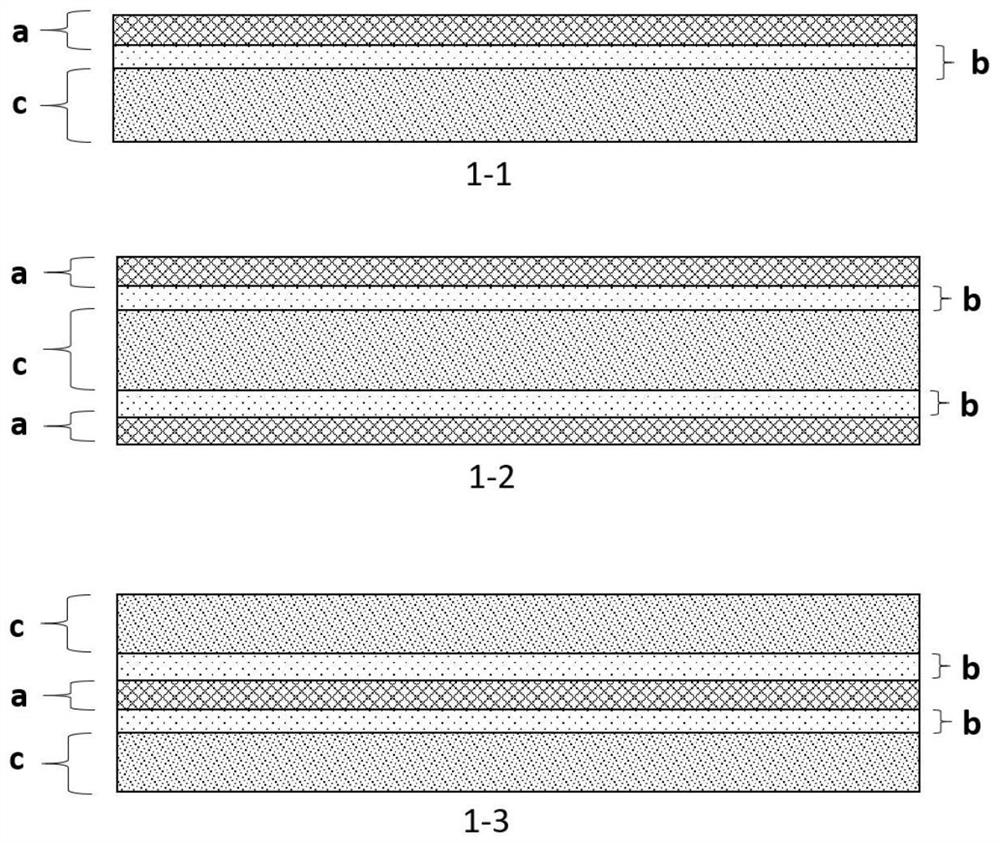

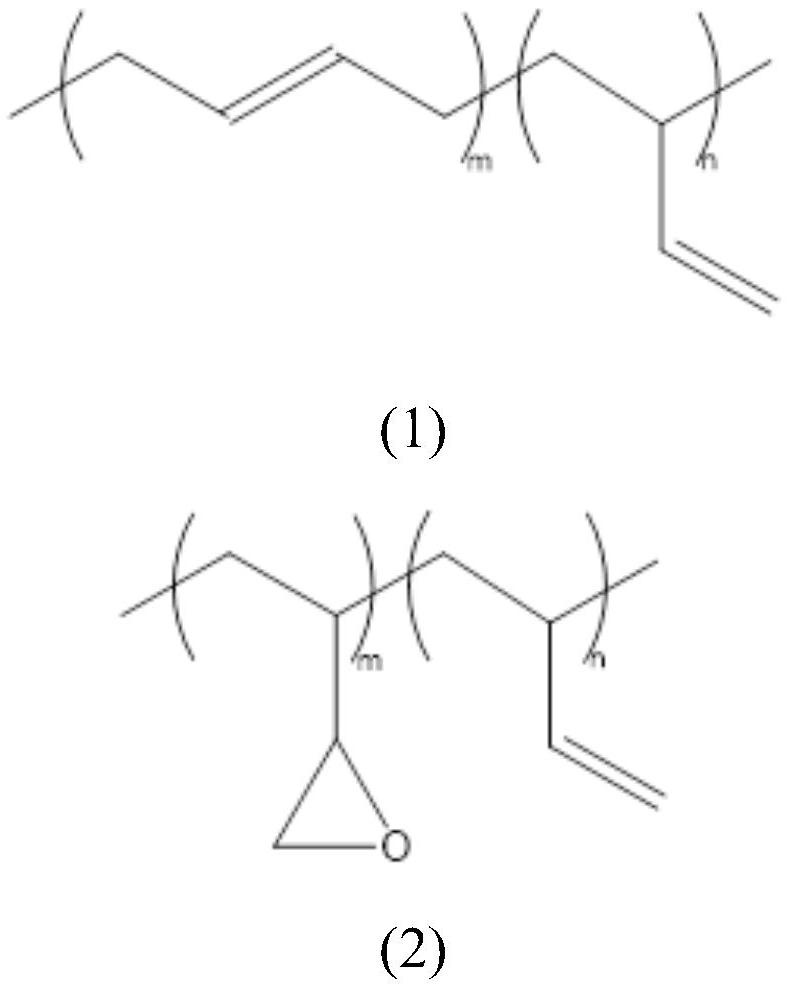

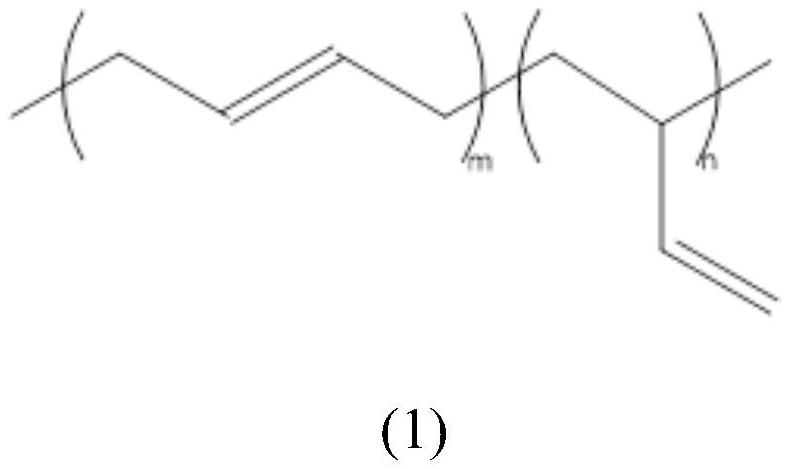

[0040] This embodiment provides a polybutadiene resin and an epoxidized polybutadiene resin composition, comprising a polybutadiene resin (A) having a number average molecular weight of the general structural formula (1) that is 1000-3000, The polybutadiene resin (B) with the number average molecular weight of structural formula (1) being 120000-300000 and the epoxidized polybutadiene resin (B) with the number average molecular weight of structural formula (2) being 1000-3000 C);

[0041]

[0042] Wherein, the weight ratio of polybutadiene resin (A), polybutadiene resin (B) and epoxidized polybutadiene resin (C) is 100:80-500:50-200.

[0043] The polybutadiene resin (A) is a low molecular weight polybutadiene resin, and the number average molecular weight is selected to be 1000-3000. The low molecular weight polybutadiene resin can effectively reduce the viscosity of the glue and facilitate its coating on the surface of the metal foil. Preferably, in order to increase the...

Embodiment 2

[0050] On the basis of Example 1, this example provides an adhesive based on polybutadiene resin and epoxidized polybutadiene resin composition, including the following components in parts by weight:

[0051] Polybutadiene resin and epoxidized polybutadiene resin composition: 100 parts;

[0052] Flame retardant (D): 0-60 parts;

[0053] Filler (E): 5-150 parts;

[0054] Leveling agent (F): 3-5 parts;

[0055] Curing agent (G): 1-15 parts;

[0056] Coupling agent (H): 0.1-5 parts.

[0057] Wherein, the polybutadiene resin and the epoxidized polybutadiene resin composition adopt the resin composition described in the first embodiment.

[0058] The type of flame retardant (D) is not particularly limited, and generally one or more of bromine-containing flame retardants and halogen-free flame retardants (nitrogen-containing flame retardants, phosphorus-containing flame retardants) can be used to use The product has the corresponding level of flame retardant properties. Prefer...

Embodiment 3

[0070] On the basis of the second embodiment, this embodiment provides a rubberized metal foil and a preparation method thereof. The preparation method of the rubberized metal foil comprises steps:

[0071] First, the adhesive is uniformly dispersed in a solvent to form a glue solution, wherein the adhesive is the adhesive described in Example 2.

[0072] Specifically, polybutadiene resin and epoxidized polybutadiene resin composition, flame retardant, filler, leveling agent, curing agent, coupling agent and other components are dispersed in a suitable solvent to prepare a glue solution , the polymer components in the glue solution are completely dissolved, and the inorganic filler is evenly dispersed in the concentrated polymer solution.

[0073] Pay attention to controlling the temperature of the glue solution during the dispersion process to avoid decomposition of the curing agent.

[0074] The solvent selection requirements for dispersion are: the polymer components cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com