When it is formed, the

cut is extruded into the egg tart mold for pressing and forming. The dough must be thin and the edge thickness is uniform. After pressing, the egg tart mold is as flat as before. It is deeply loved by customers. However, the egg tart

skin The production has not yet realized automated production, the production equipment is semi-automated, the entire production process requires manual participation, and manual participation will inevitably bring about high labor costs; artificial

pollution of products, large errors, and inconsistent product quality standards And other issues, with the development of automation, all walks of life are developing towards the automation industry, so the

automatic processing and production of egg tarts is also inevitable

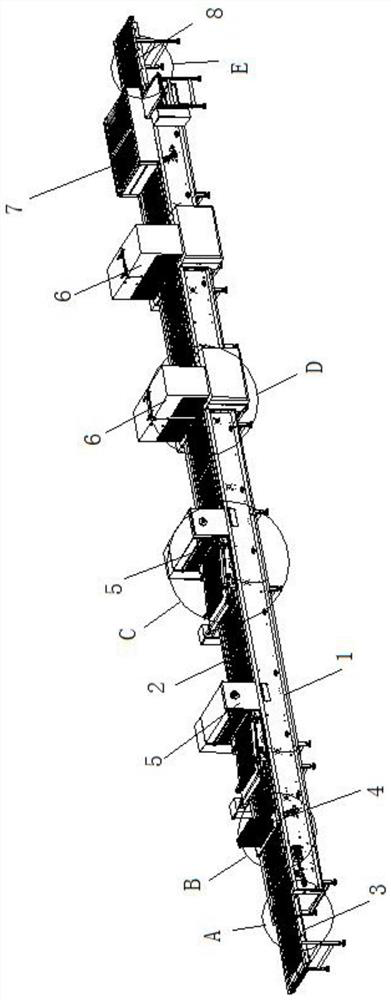

[0003] Patent: 201710743060.6, which discloses a

fully automatic egg tart

skin production and forming equipment. The structure includes a frame, a conveying mechanism installed on the frame, an automatic

cup feeding device, a quantitative

cutting device, a forming device, an automatic cup opening device and Back-stage conveying device, wherein the conveying mechanism is set to reciprocate along the frame, and successively passes through the automatic

cup feeding device, quantitative

cutting device,

extrusion forming device and automatic cup opening device in the process of moving from front to back along the frame , and the conveying mechanism is provided with multiple rows of cup-setting columns distributed along the direction of motion, the automatic

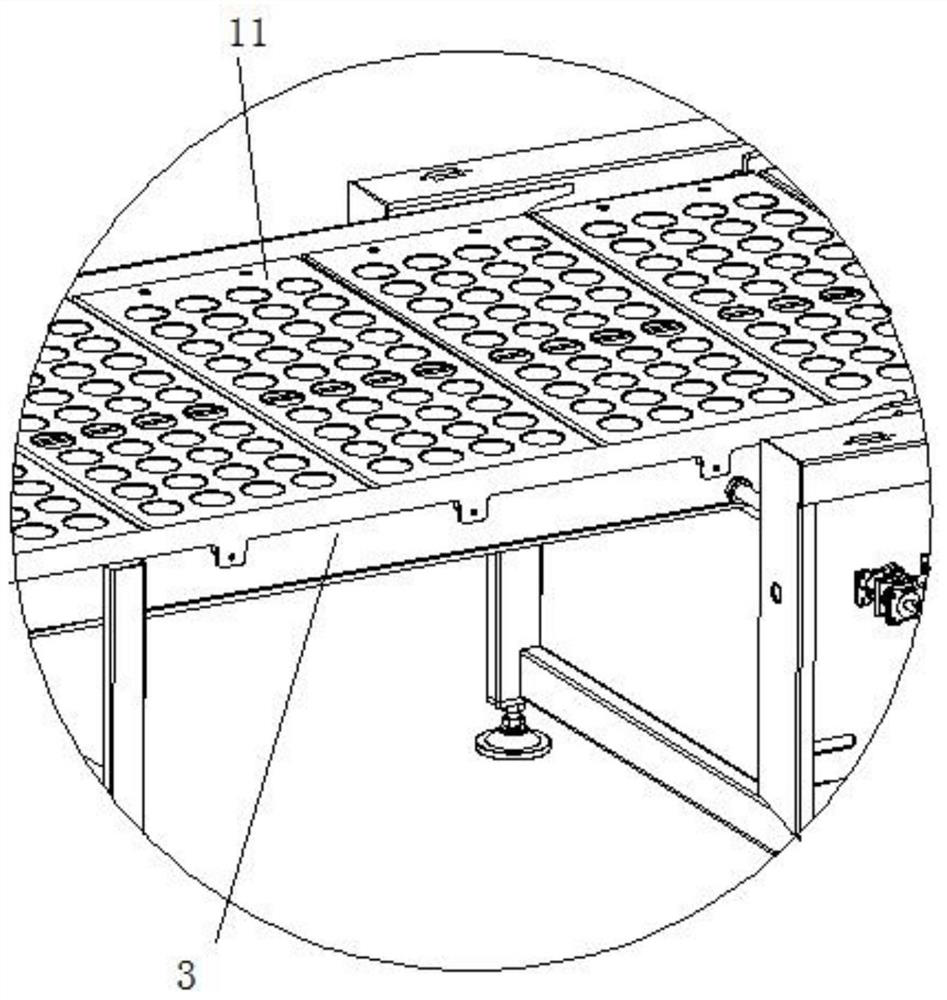

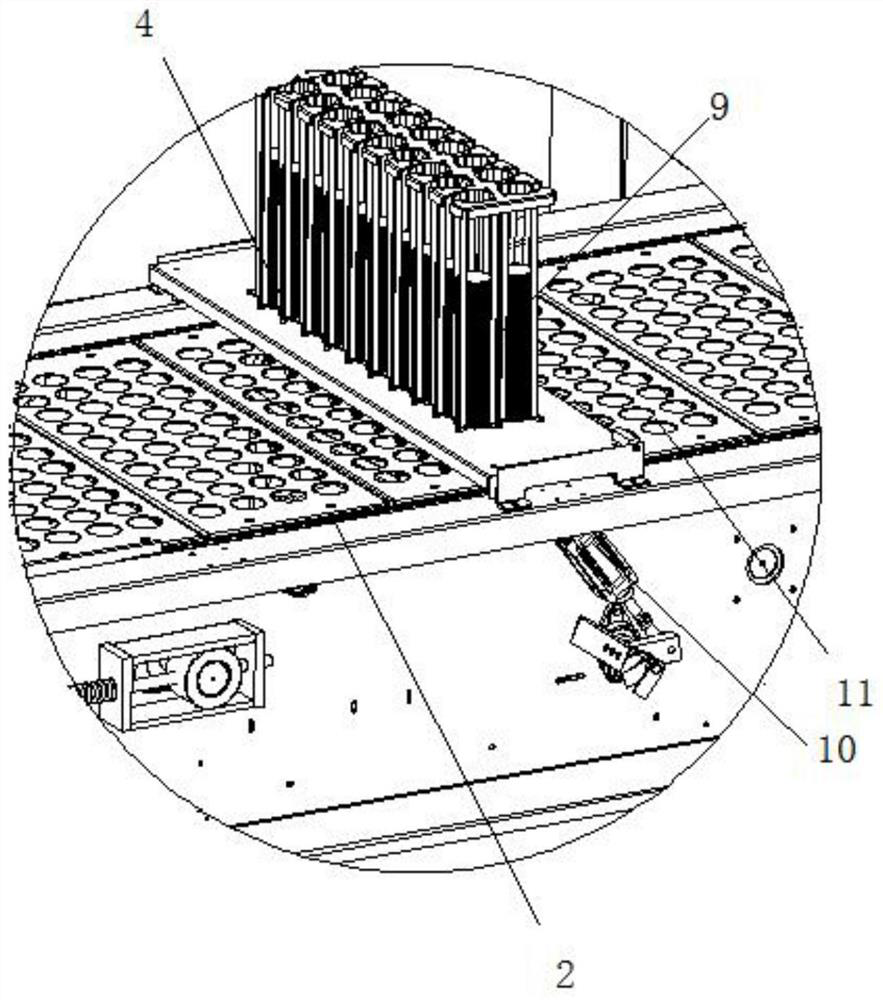

cup feeding device is set to automatically provide tart cups to the cup-setting column, and the quantitative

cutting device is set to automatically supply tart cups to the cup-setting column. The egg tart skin raw materials

cut into pieces are provided in the

machine, the

extrusion forming device is set to automatically extrude the egg tart skin raw materials in the tart cup, and the automatic cup opening device is set to automatically squeeze the After forming, the tart cups of egg tart skin are lifted from the cup holder and pushed into the rear conveying device; although its structural design realizes the automatic production of egg tarts to a certain extent, there are many disadvantages in the production process, which affect the product quality. The quality and normal operation of continuous

processing and production, the specific disadvantages are as follows:

[0004] (1) The circular

conveyor belt adopts a simple circular conveyor chain to arrange multiple rows of cup rails along the direction of motion, and each row of cup rails is provided with six horizontally evenly distributed cup holes for continuous circular transportation. The cup rail is fixed to the circular conveyor chain, and one line can only process one type of egg tart, which has poor versatility. When

processing egg tarts of different models or shapes, it is necessary to replace the entire circular conveyor chain, which is troublesome to replace , and due to the position setting of each processing equipment on the production line, it needs to reach the set position during its

continuous production to realize the corresponding function, so repeated debugging is required, the

workload of replacement operation and debugging is relatively large, and the cost high

[0005] (2) Although the automatic cup feeding device adopted by it can realize the process of feeding cups, since the bottom end of the cup rail adopts the structure of elastic steel sheet, the shrapnel is set so that it can be sucked in when the vacuum

nozzle is pulled downward. The tart cups change from the initial state to the deformed state to allow the tart cups to break away from these shrapnels, and once the tart cups are free from these shrapnels, these shrapnels return from the deformed state to the original state, thereby preventing the next tart cup from being sucked together with the tart cup The principle of separation together, but in the actual operation process, because the material of the aluminum bracket is relatively soft, the two are closely attached when superimposed. Although the shrapnel has a certain blocking effect, its limit performance is poor, so when the following When the aluminum bracket is deformed by force and goes down, the aluminum bracket above it will also be deformed by force. If the deformation is too large, it will fall directly with the aluminum bracket below. If the deformation is too small, sometimes it will be stuck in the spring. Position, resulting in severe deformation, leading to bad cup phenomenon;

[0006] (3) The structure of

extrusion molding is used in the comparison document, which adopts a common molding structure. Although the process of

compression molding can be realized, the existing mold structure is simple. During its production and processing, there will be the following Problem: On the one hand, because the aluminum film of the egg tart is relatively light, it is unstable when it is clamped in the forming cavity of the lower mold, which affects the placement and molding of the dough blank; on the other hand, when the egg tart blank is formed, it is easy to stick , it is easy to stick to the mold core of the upper mold when it is pressed down, which is inconvenient to remove the mold and affects the quality of the egg tart. If there is sticking on the mold core when the mold is removed, it needs to be dealt with in time to improve production efficiency. It brings troubles, which affects the processing and production of

regular production, and the production efficiency is low;

[0007] (4) Although the automatic cup opening device also adopts a mechanism for ejecting and transferring material that cooperates up and down to complete the removal operation, it adopts a mechanism for direct ejection, and the momentary stability of the ejection of the egg tart is poor, and it is easy to slip. At the same time, when taking it out, the pushed egg tarts are pushed onto the

conveyor belt. During the pushing operation, the stability of the egg tarts is poor, and the order in which they fall onto the finished product

conveyor belt will appear disorderly, thus affecting the subsequent automatic packaging process. , needs manual assistance to sort it out, the manual labor intensity is high, and manual participation in contact production will affect the quality of the product to a certain extent, and cannot meet the requirements of

batch processing and production

[0008] In summary, in the actual automated production, there are serious deficiencies in the comparison files, so it needs to be improved to meet the needs of

mass automated production

Login to View More

Login to View More  Login to View More

Login to View More