Sandwich nori baking machine set capable of realizing continuous feeding

A technology of sandwiching seaweed and unit, applied in baking, baking workshop, food oven and other directions, can solve the problems of unit components and ground adhesion pollution, affecting the working efficiency of the unit, complicated structure design of the unit, etc., and achieves low cost and structure. Simple and easy to promote the effect of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

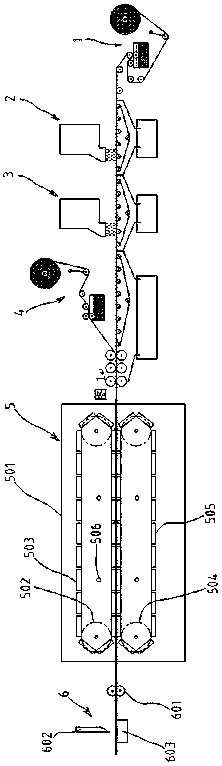

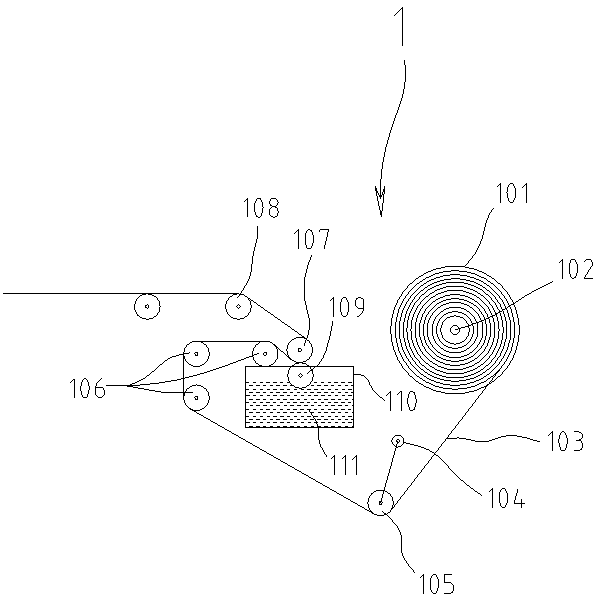

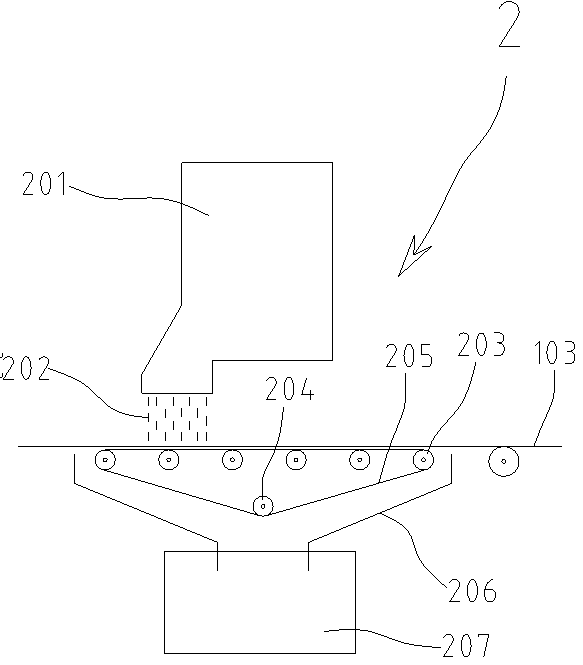

[0022] Embodiment 1: see figure 1 , a continuous feeding sandwich seaweed baking unit, the unit includes a lower laver roll supply assembly 1, a first sandwich material supply assembly 2, a second sandwich material supply assembly 3, an upper laver roll supply assembly 4, and a baking assembly 5 And the cutting assembly 6, the above-mentioned devices are sequentially arranged along the front end of the unit, wherein the lower layer of laver roll supply assembly 1 provides the unit with continuous lower layer of laver sheet rolls, and the upper layer of laver roll supply assembly 4 provides the unit with continuous upper layer of laver Sheet coil material; the first sandwich material supply assembly 2 and the second sandwich material supply assembly 3 are horizontally arranged directly above the lower laver sheet coil material in turn, so that the sandwich material scattered by the sandwich material supply assembly can fall to the lower laver sheet roll On the upper surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com