Continuous supersonic sand erosion test table and test method thereof

A supersonic, test-bed technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of high cost, hidden dangers to the safety of test personnel, and inability to achieve supersonic speed, and achieve the effect of low cost and continuous supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

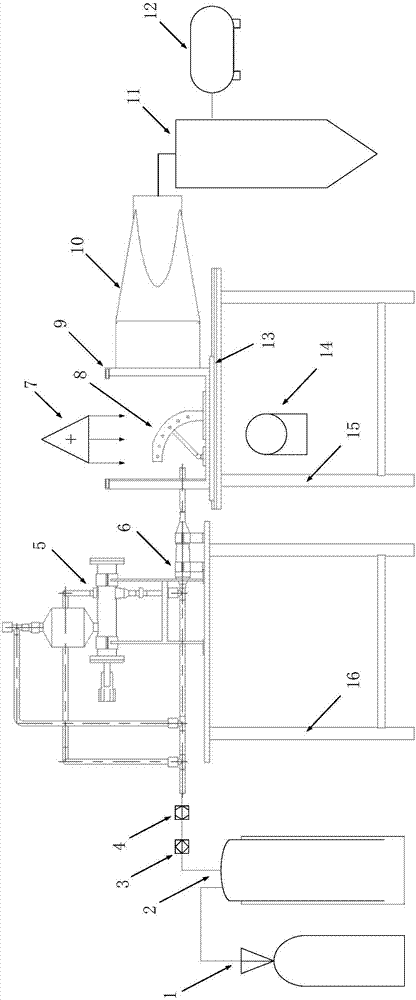

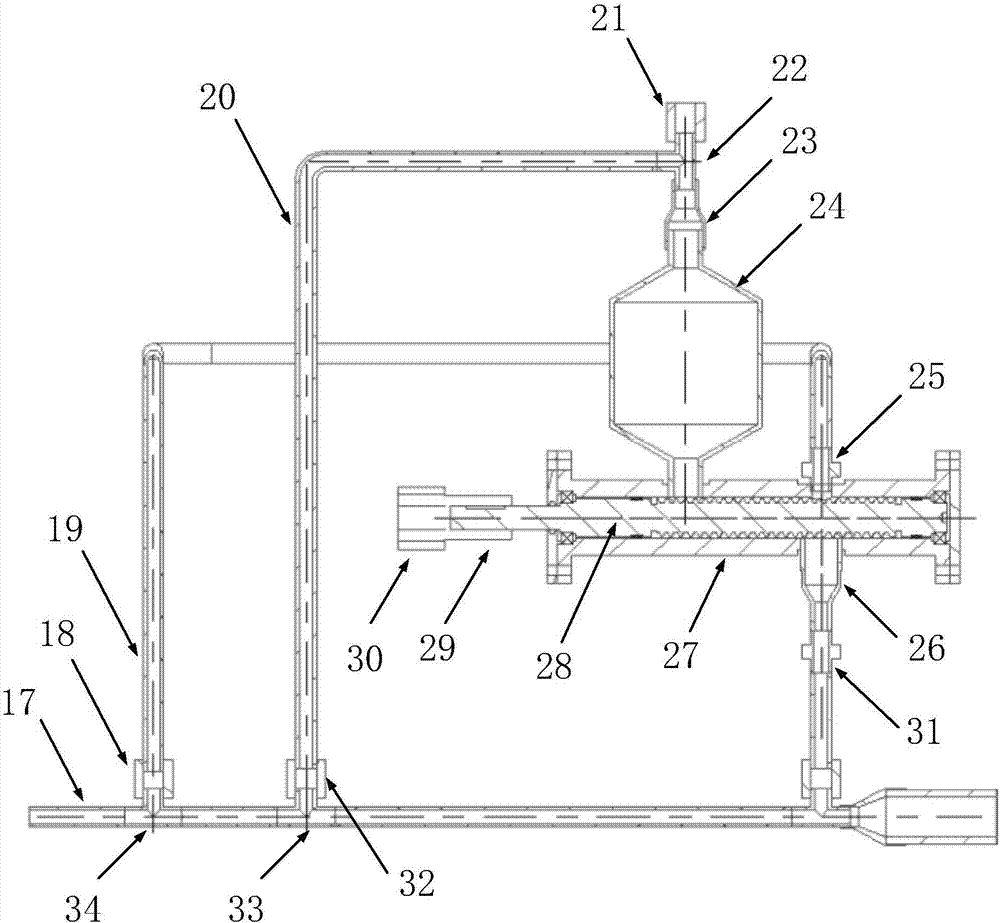

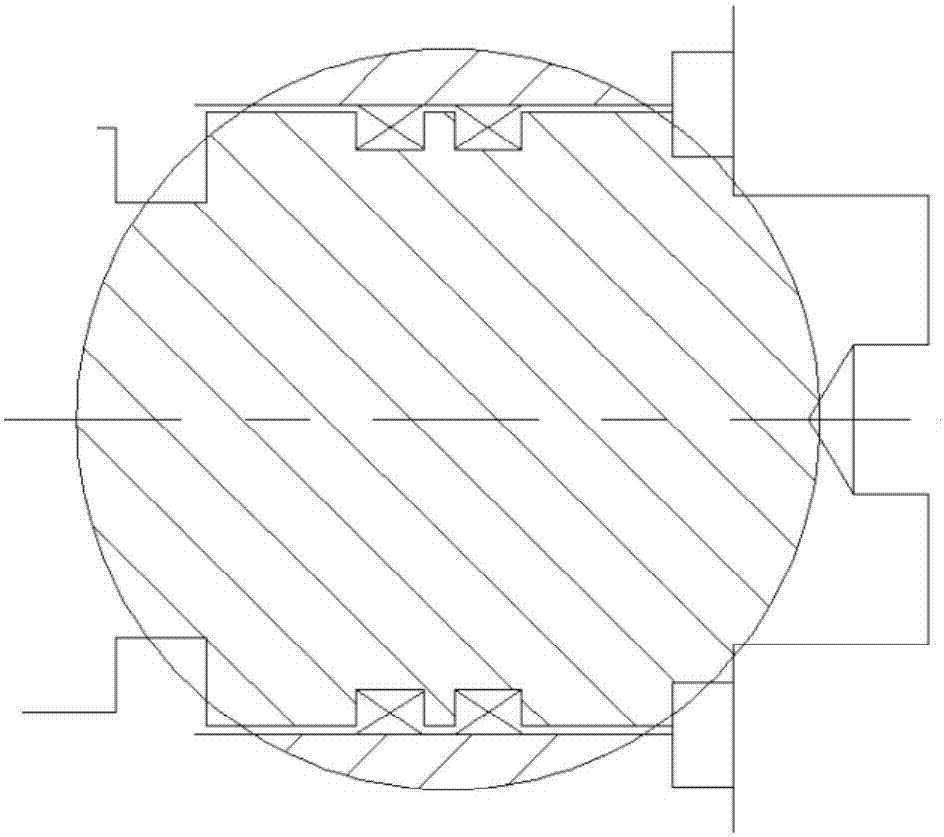

[0037] Attached below figure 1 , attached figure 2 , attached image 3 , attached Figure 4 And attached Figure 5 The specific embodiment of the present invention will be further described.

[0038] figure 1 It is a general structure diagram of the present invention. The right side of the gas cylinder group 1 composed of 5 high-pressure cylinders is the pressure regulator tank 2, the right side of the pressure regulator tank 2 is the pressure control valve 3, the right side of the pressure control valve 3 is the solenoid valve 4, and the solenoid valve 4 is Control the switch of the main air flow, the main air is respectively connected to the sand supply device 5 and the sand blasting device 6, and the sand supply device 5 and the sand blasting device 6 are fixed on the test table 16; the right side of the sand blasting device 6 is the test piece fixture 8, and the test Fixture 8 is fixed in test chamber 9, and the lower side of test chamber 9 is connected with transla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com