Integral seal jack

An overall sealing and jacking technology, which is applied in the direction of lifting devices, piston rods, engine components, etc., can solve the problems of easy falling off of the electroplating layer, great social harm, waste of raw materials, etc., to enhance safety and reliability, and overcome unstable quality , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

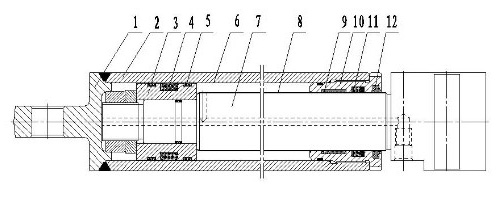

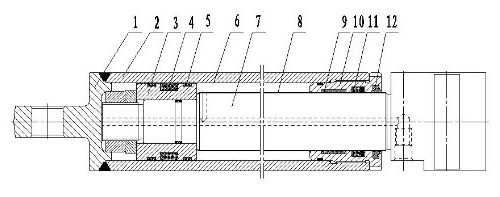

[0014] like figure 1 As shown, the overall sealing jack is composed of a cylinder body, a piston rod 7, a piston assembly and a cylinder port assembly, the cylinder body is composed of a base 1 and a cylinder barrel 2, and the base 1 and the cylinder barrel 2 are connected together by welding; the piston rod 7 It is a stepped rod with a shoulder at one end, and the piston rod 7 is set in the cylinder 2; the piston assembly is set on the piston rod 7, positioned by the shoulder of the piston rod 7, and fixed on the piston rod 7 by a nut; The port assembly is composed of a guide sleeve 10, a guide ring 9, a seal 11 and a dustproof ring 12. The guide sleeve 10 is connected to the cylinder 2 through a nut, and the guide ring 9, the seal 11 and the dustproof ring 12 are mounted on the guide sleeve 10. Inside, it is characterized in that: the piston assembly is composed of a piston 3, two piston guides 5 and a piston seal 4, and is an integral piston, and the two piston guides 5 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com