High-performance support component based on self-reset energy dissipation

A support member, self-reset technology, applied to building components, on-site preparation of building components, pillars, etc., can solve problems such as insufficient energy consumption, avoid structural collapse, avoid support buckling damage, and reduce temperature sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

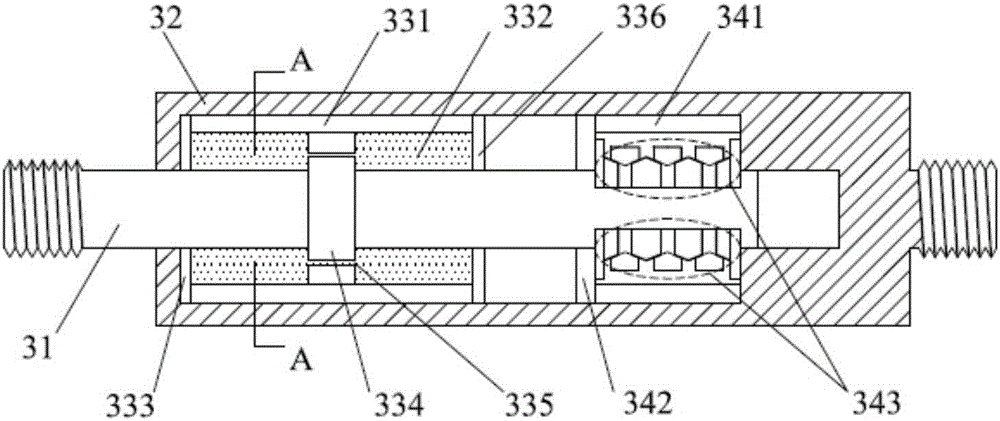

[0037] A high-performance support member based on self-resetting energy consumption, including self-resetting energy-consuming parts 3, and main body support cylinders respectively installed at both ends of self-reset energy consumption parts 3. The energy dissipation component 3 includes an outer cylinder 32 and a piston guide rod 31. The outer cylinder 32 is also provided with a viscous damper chamber 33 and a shape memory alloy ring spring chamber 34. One end of the piston guide rod 31 passes through the viscous damper in turn. The other end of the chamber 33 and the shape memory alloy ring spring assembly chamber 34 is fixedly connected to a main body support cylinder, and the outer cylinder 32 is also fixedly connected to another main body support cylinder.

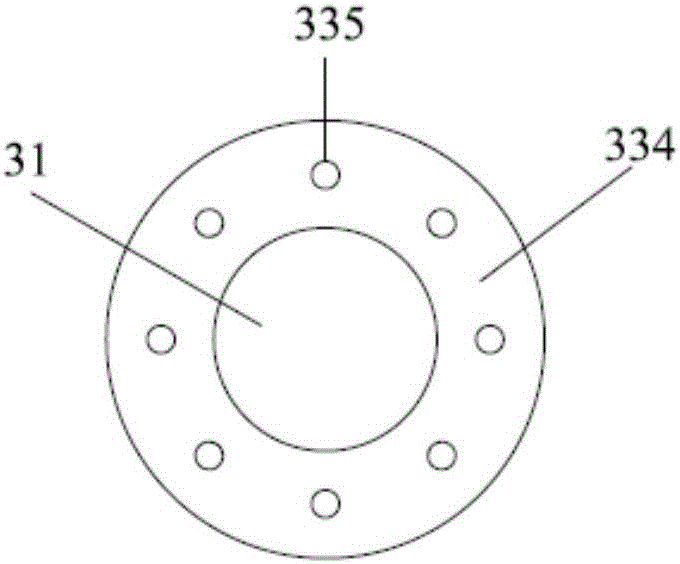

[0038] The viscous damper cavity 33 includes a viscous damper cylinder fixed in the outer cylinder 32, the viscous damper cylinder is filled with damping liquid 332, and the viscous damper cylinder includes a viscous ...

Embodiment 2

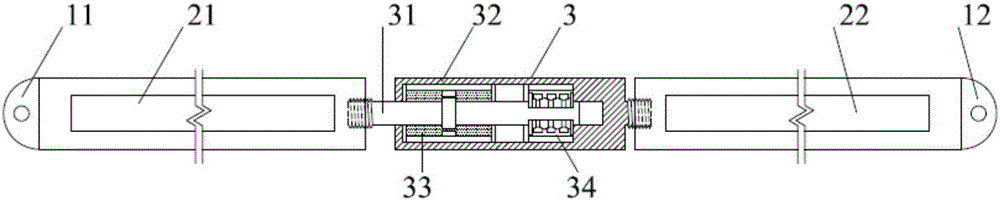

[0041] like figure 1 As shown, a high-performance support member based on self-resetting energy-consuming core components includes end joints (left end joint 11, right end joint 12), main body support cylinder (left main body support cylinder 21, right main body support cylinder 22) and self-resetting energy-consuming components 3. The two ends of the self-resetting energy-consuming part 3 are respectively connected with the two main body support cylinders through threaded joints, the other end of the left main body support cylinder 21 is welded with the left end joint 11, and the other end of the right main body support cylinder 22 is welded with the right end Connector 12.

[0042] like figure 2 The schematic diagram of the structure of the self-resetting energy-consuming part 3 shown, in the event of an earthquake, the reciprocating motion of the piston guide rod 31 causes the reciprocating motion of the piston 334, and the reciprocating motion of the piston 334 in the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com