Hydraulic retarder

A hydraulic retarder and heat exchanger technology, applied in the direction of liquid resistance brakes, brake types, mechanical equipment, etc., can solve the problem of affecting the braking effect of the hydraulic retarder, slow sliding of the piston, and affecting the oil supply of the retarder To achieve the effect of improving heat exchange efficiency, increasing oil inlet speed and reducing reverse resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in combination with specific embodiments.

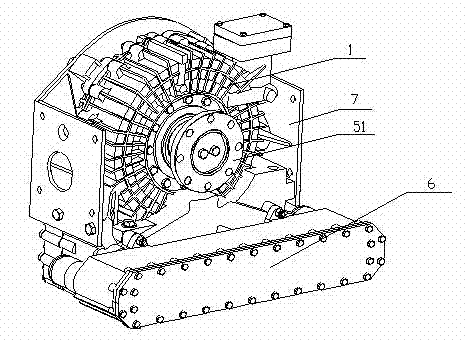

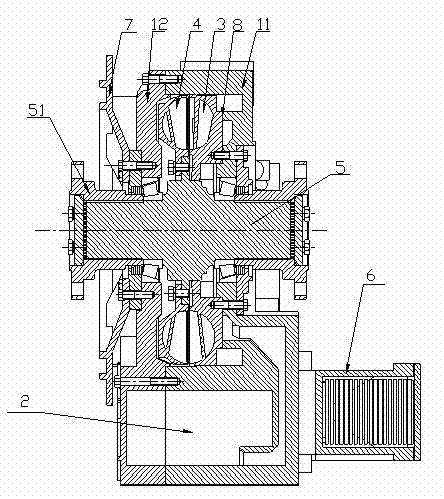

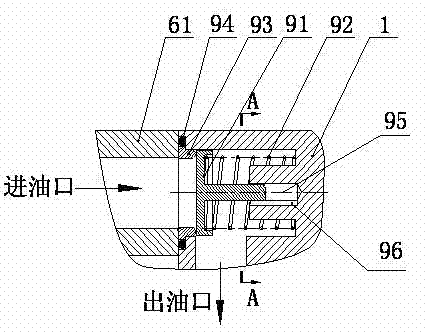

[0031] see figure 1 and figure 2 : The hydraulic retarder includes a hydraulic retarder housing 1, an oil storage tank 2, a stator 3, a rotor 4 and a heat exchanger 6, the stator 3 and the rotor 4 are installed in the working chamber, and the oil storage tank 2 and the working chamber are arranged in Inside the hydraulic retarder shell 1, the heat exchanger 6 is fixedly installed outside the shell. The stator 3 is connected to the hydraulic retarder housing 1 through bolts, and the rotor 4 is mounted on the spline shaft 5 through bolts and can rotate with the spline shaft 5 . On the stator 3 and along the circumferential direction of the stator 3, an oil inlet a33 and an oil outlet are provided. The oil inlet a33 of the stator 3 communicates with the oil storage tank 2 through the first oil inlet, and the oil outlet of the stator 3 passes through the oil outlet. The pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com