Backdrilling plug hole panel and machining method thereof

A processing method and back-drilling technology, which are applied in the field of back-drilling plug hole plates and their processing, can solve the problem of easy generation of voids in back-drilling, and achieve the effects of reducing voids, reducing the probability of occurrence, and avoiding voids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for processing a back-drilled plug orifice plate, comprising the following steps:

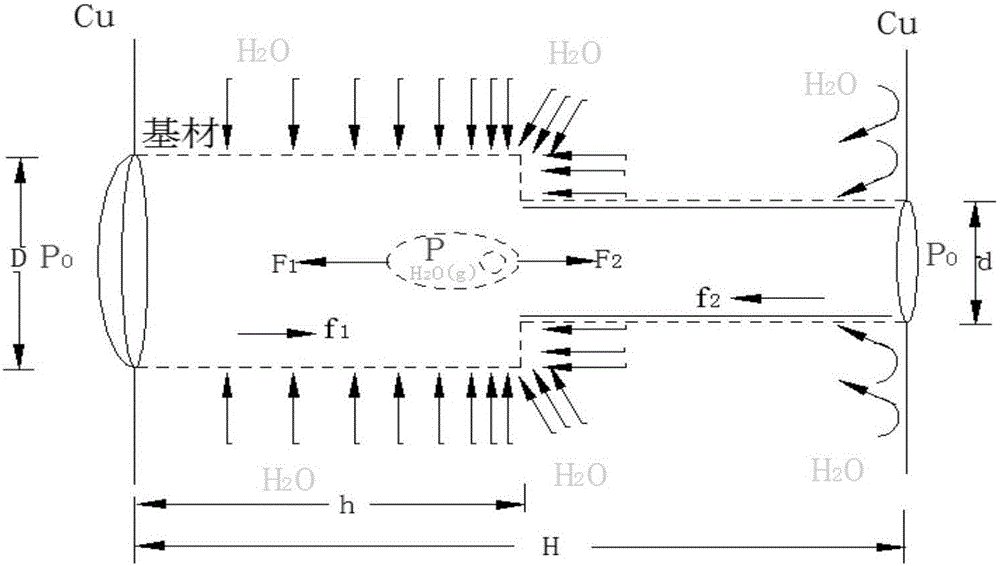

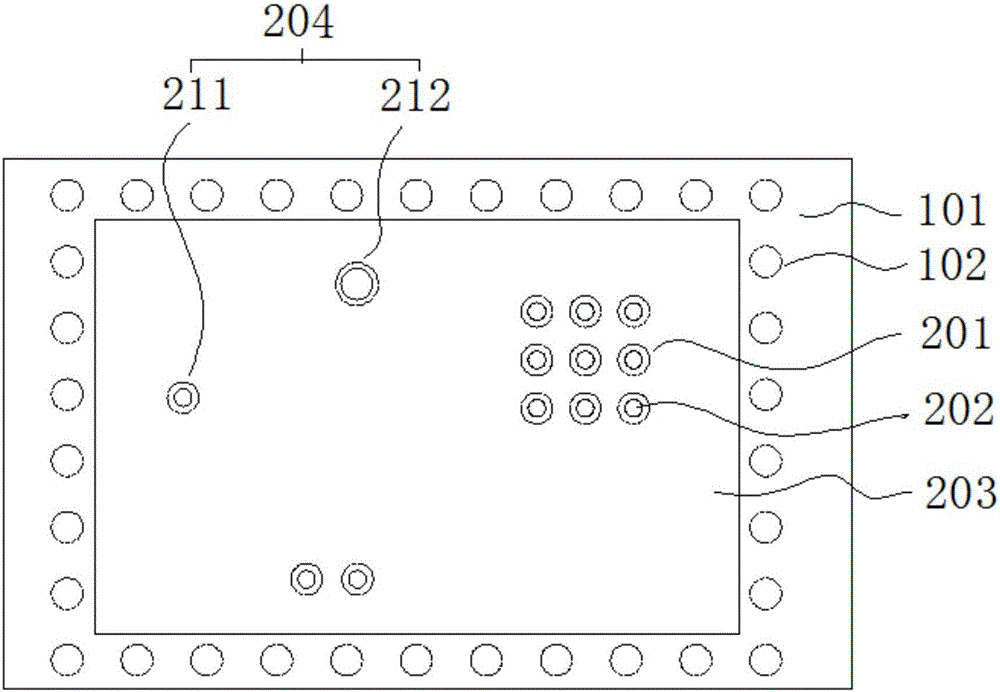

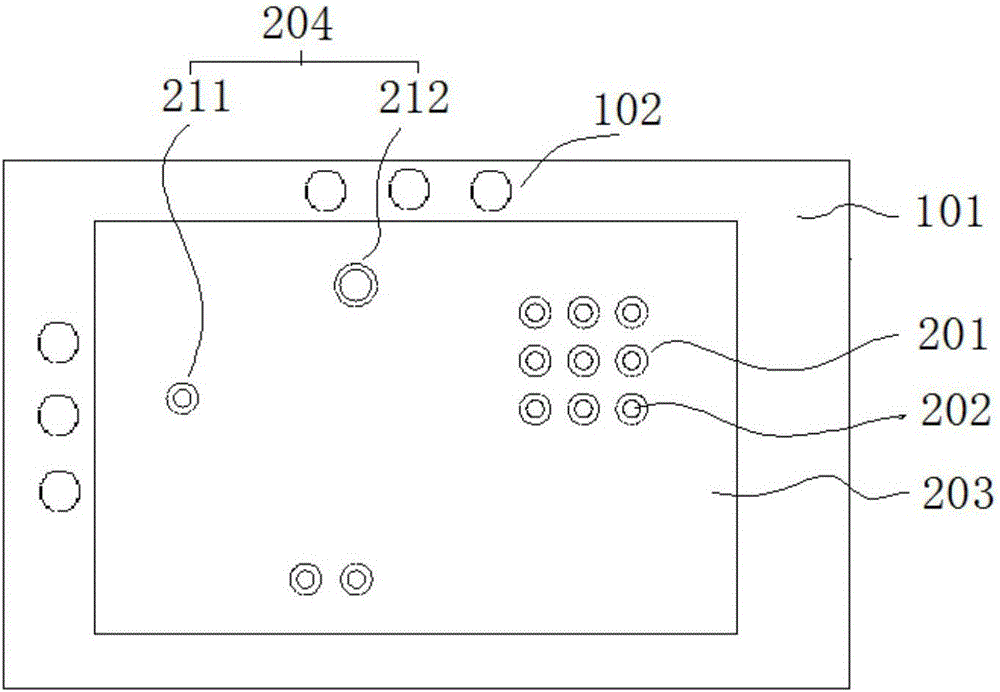

[0050] 1) Plating holes after back-drilling; back-drilling the metallized holes on the substrate, the back-drilled section is a non-metallized hole, the remaining section maintains the metallization feature, and the metallized hole is thickened with copper plating; the structure of the substrate is as follows figure 2 As shown, there is an edge banding area 101 outside the graphic area 203, and a back-drilled position through hole 202 is provided in the graphic area, including dense back-drilled holes 201 and isolated back-drilled holes 204, wherein the isolated back-drilled holes include small back-drilled holes 211 and large back drilling 212; in step 1), an auxiliary hole 102 is provided in the edge banding area; the auxiliary hole is a non-metallized hole, the diameter of the auxiliary hole is 0.9mm, and the hole spacing is 15mm;

[0051] 2) Baking board: bake the board at ...

Embodiment 2

[0056] A method for processing a back-drilled plug orifice plate, comprising the following steps:

[0057]1) Back-drilling and plating holes; back-drilling the metallized holes on the substrate, the back-drilled section is a non-metallized hole, the remaining section maintains the metallization feature, and the metallized hole is thickened with copper plating;

[0058] 2) Baking board: bake the board at 160°C; for substrates with water absorption > 0.1%, bake the board for 6 hours; for substrates with water absorption ≤ 0.1%, bake the board for 4 hours.

[0059] 3) Plug hole: use resin to fill the back drilled hole;

[0060] 4) Curing: Curing the resin filling the back-drilled holes at 160°C for 60 minutes.

[0061] The back-drilled plug orifice plate processed in this embodiment has no visible void in the back-drilled plug hole.

Embodiment 3

[0063] A method for processing a back-drilled plug orifice plate, comprising the following steps:

[0064] 1) Back-drilling and plating holes; back-drilling the metallized holes on the substrate, the back-drilled section is a non-metallized hole, the remaining section maintains the metallization feature, and the metallized hole is thickened with copper plating;

[0065] 2) Baking board: bake the board at 140°C; for substrates with water absorption > 0.1%, bake the board for 8 hours; for substrates with water absorption ≤ 0.1%, bake the board for 6 hours.

[0066] 3) Plug hole: use resin to fill the back drilled hole;

[0067] 4) Curing: Curing the resin filling the back-drilled holes at 140°C for 40 minutes.

[0068] The back-drilled plug orifice plate processed in this embodiment has no visible void in the back-drilled plug hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com