Complex production process intelligent modeling method

A technology of manufacturing process and modeling method, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of complex processing technology, difficulty and cost of information generation and maintenance, and high demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The manufacturing process of the product defines the product structure of any product and semi-finished product and the raw materials or materials required in the production process. It is the most important basic data of information systems such as ERP, MES and APS in modern manufacturing enterprises.

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

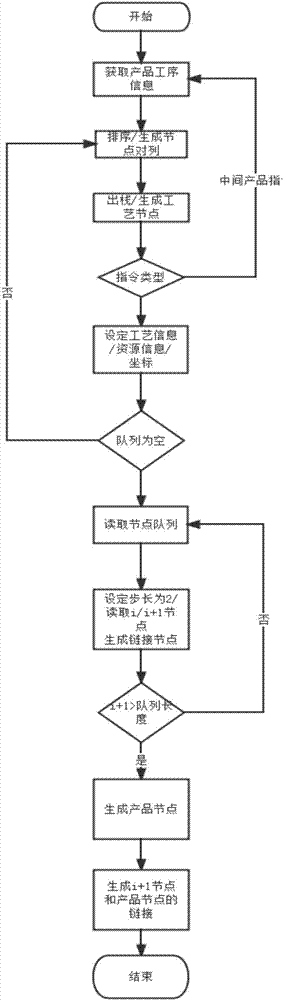

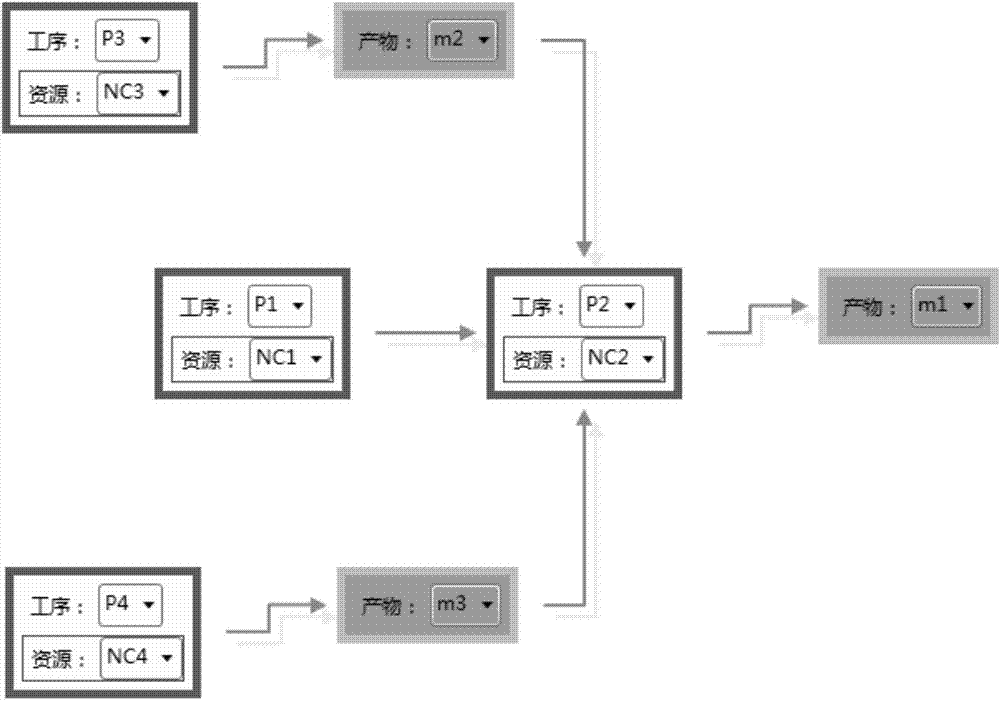

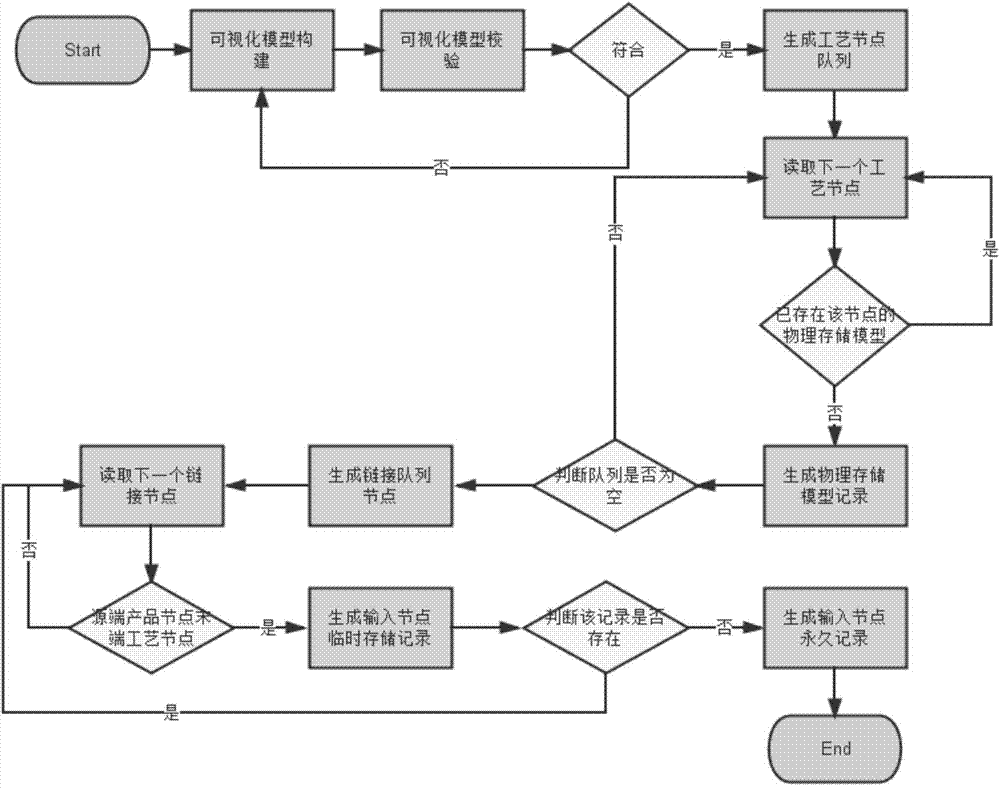

[0038] figure 1 It is a flow chart of the transformation from the physical storage model to the visualized logical model of the present invention. This flow chart describes the transformation process from the physical storage model to the visual logical model. The input source is the product information of the order, which is the final product node of the visual model. According to the manufacturing process information of the product, the process node queue of the product is formed in sequence. If a process requires other products, a process node queue of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com