Intelligent modeling method in industrial polyester production process

A modeling method and production process technology, applied in the field of intelligent modeling, can solve the problems of increasing the difficulty of modeling, the model cannot fully reflect the actual state of the production process, etc., and achieve the effect of accurate model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

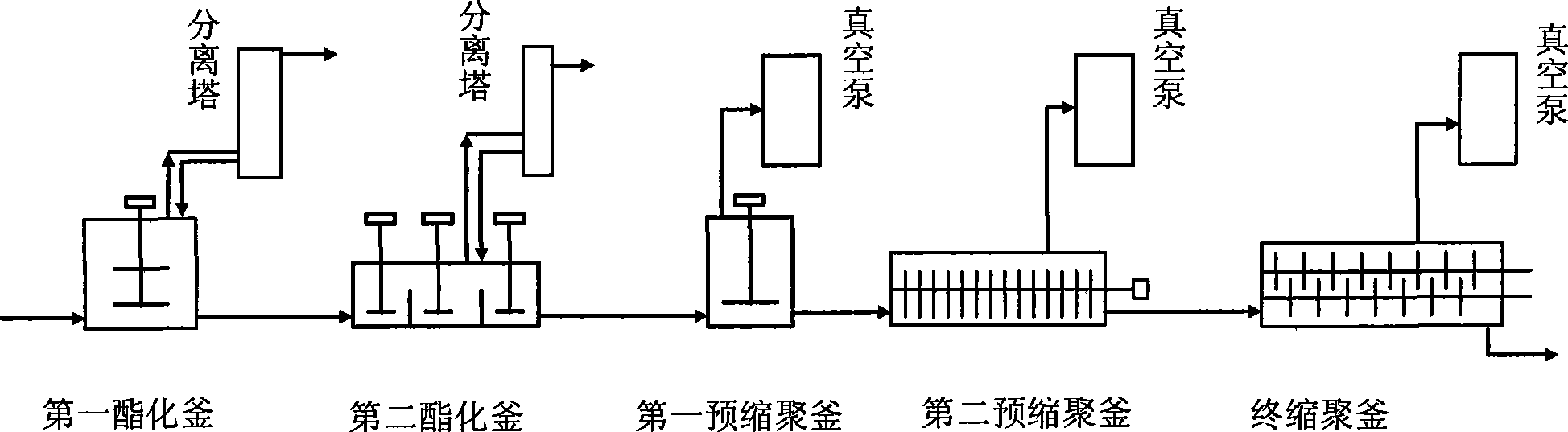

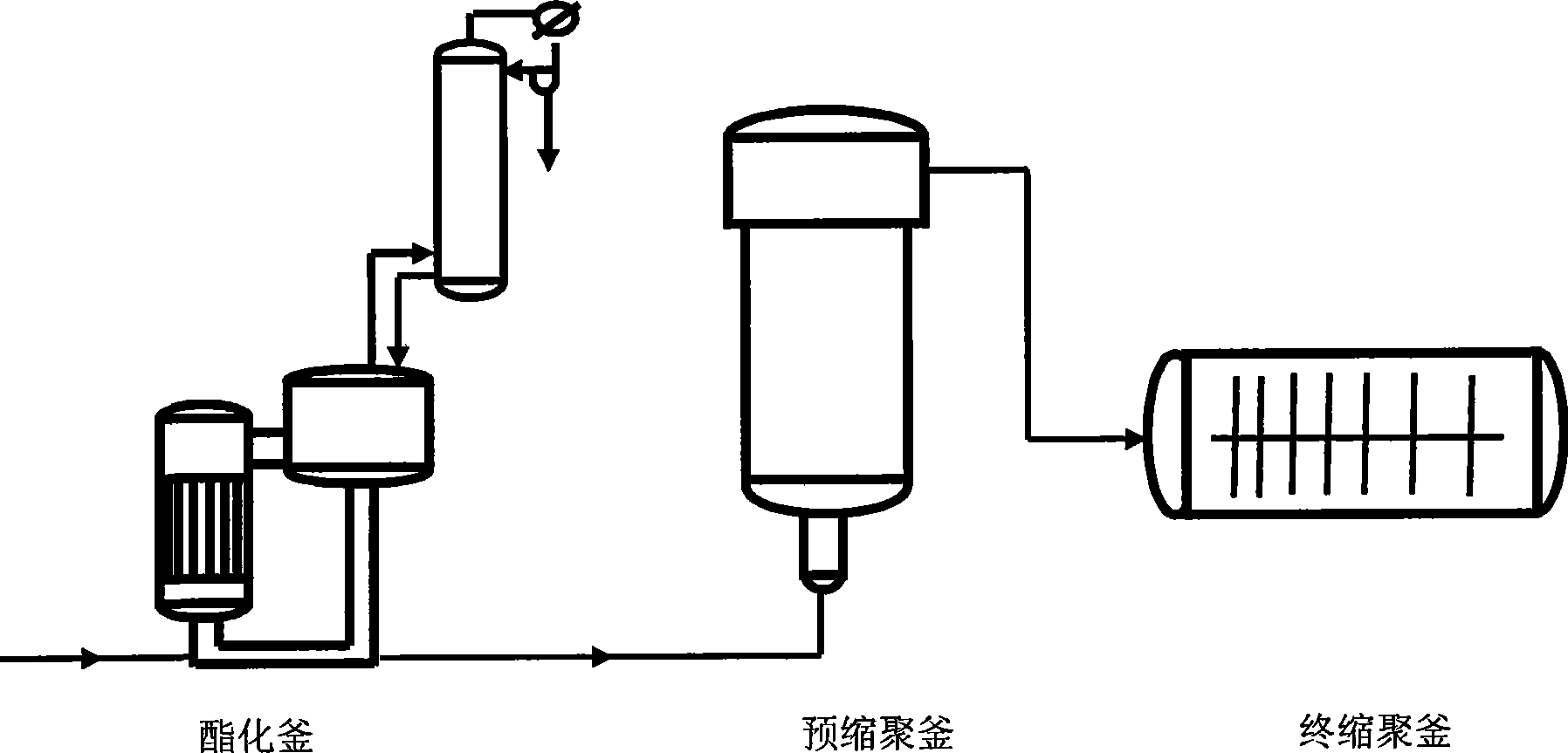

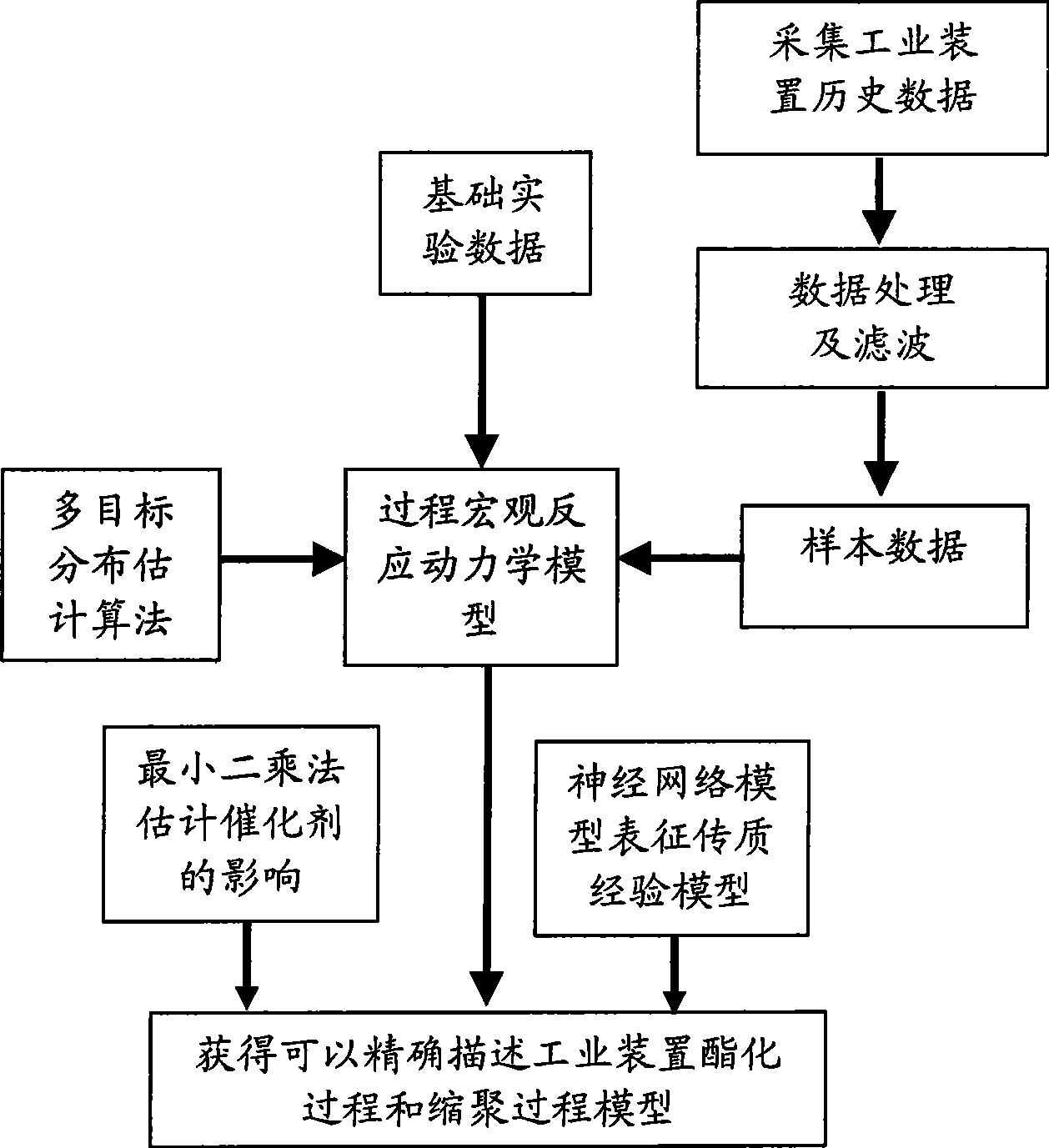

[0023] Such as image 3 As shown, the modeling method of the polyester production process mechanism model includes the following steps:

[0024] Step 1. Collection and processing of industrial data.

[0025] Collect real-time and historical data of industrial reactors, including reactor temperature, pressure, liquid level, feed amount, feed composition, composition of gas phase products, flow rate of gas phase products, composition of liquid phase products, flow rate, liquid phase polymer Intrinsic viscosity, carboxyl end concentration. For factories equipped with distributed control systems, production data such as temperature and pressure are generally collected in seconds, and quality data such as carboxyl-terminal concentration and intrinsic viscosity of products are generally analyzed every 8 hours. The data of 2 hours before and after the analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com