Compound type fuel cell cathode catalyst NGPC/NCNTs and preparation method thereof

A fuel cell cathode and electrocatalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as high cost, and achieve the effects of accelerating mass transfer process, good conductivity, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

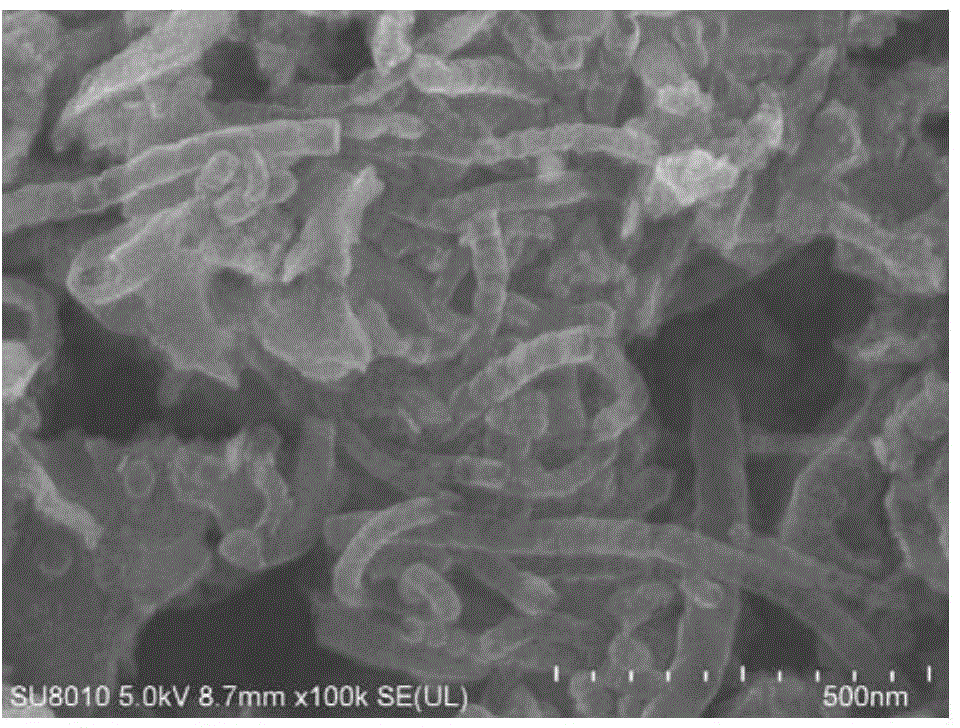

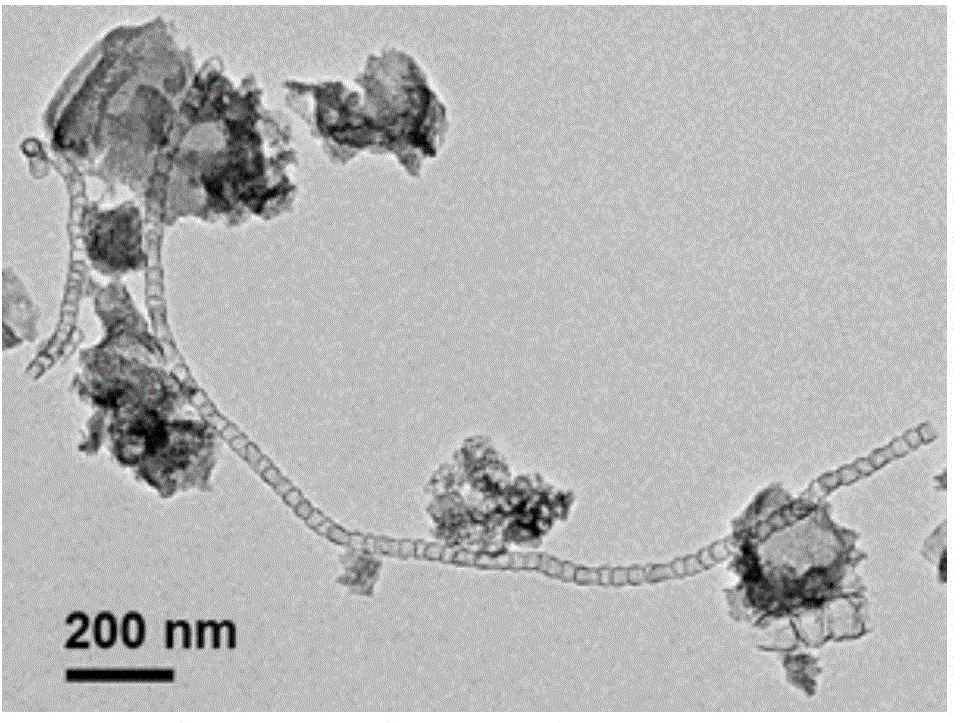

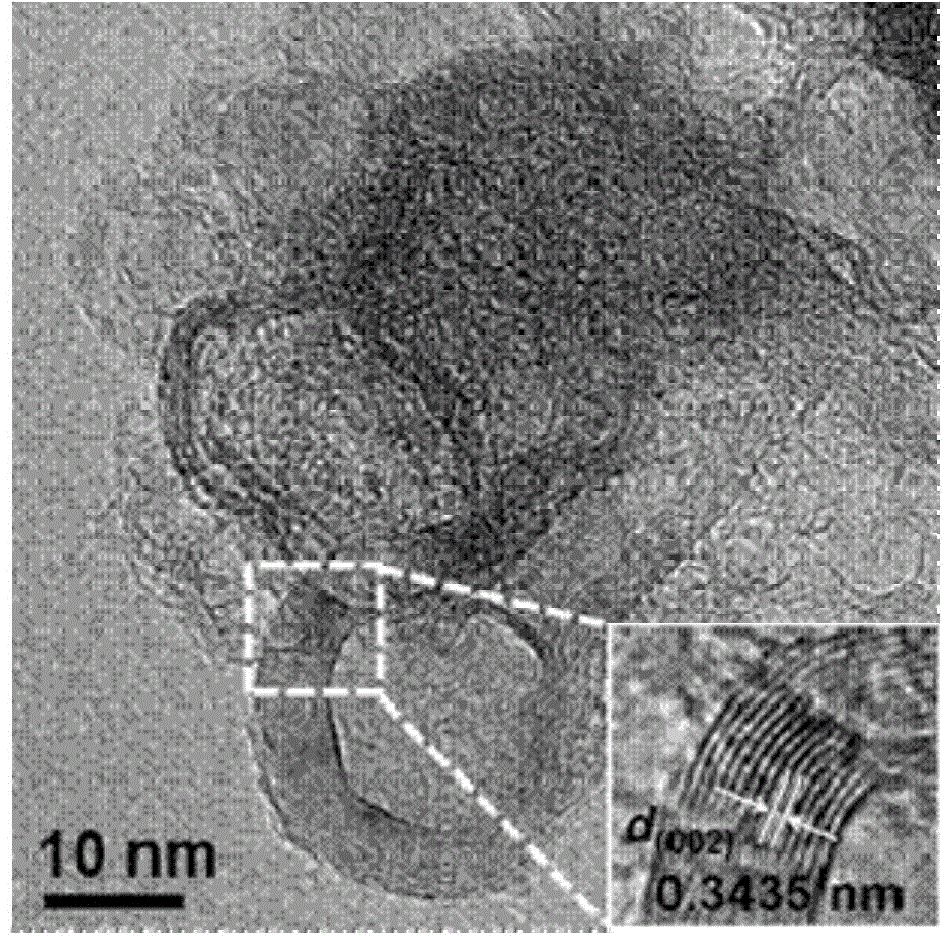

Image

Examples

Embodiment 1

[0026] (1) Pre-carbonize MOF-5(Zn) at 550°C for 1 hour under nitrogen atmosphere, wash with 1M hydrochloric acid to remove metal components, wash with water until neutral, and dry at 80°C to obtain pre-carbonized porous carbon powder ;

[0027] (2) Add 0.1 g of pre-carbonized porous carbon powder into 10 mL of aqueous solution dissolved with 0.3 mmol of nickel formate, stir at room temperature for 12 hours, evaporate the water to dryness at 50 °C with a rotary evaporator, and dry the obtained solid sample 1. After grinding, heat treatment at 1000°C for 3 hours under a nitrogen atmosphere, and then hydrothermally treat the resulting product with a mixture of 10M hydrochloric acid and 1.25wt.% hydrogen peroxide at 160°C for 24 hours, then wash with water until neutral, and then dry it under vacuum at 60°C to obtain graphitized porous carbon;

[0028] (3) Place 0.1 g of the above-mentioned graphitized porous carbon in 20 mL of 34 wt.% sulfuric acid solution and soak for 4 hours,...

Embodiment 2

[0031] (1) Pre-carbonize ZIF-8(Zn) at 500°C for 1 hour under an argon atmosphere, wash with 1M hydrochloric acid to remove metal components, wash with water until neutral and dry at 85°C to obtain pre-carbonized porous carbon powder end;

[0032] (2) Add 0.1 g of pre-carbonized porous carbon powder into 10 mL of aqueous solution dissolved with 0.6 mmol of ferric chloride, stir at room temperature for 12 hours, evaporate the water to dryness with a rotary evaporator at 50 ° C, and dilute the obtained solid After the sample was dried and ground, it was heat-treated at 1000°C for 3 hours under an argon atmosphere, and the obtained product was hydrothermally treated with a mixture of 10M hydrochloric acid and 1.25wt.% hydrogen peroxide at 180°C for 24 hours, then washed with water to neutrality, and vacuumed at 70°C Dried to obtain graphitized porous carbon;

[0033] (3) 0.1 g of the above-mentioned graphitized porous carbon was placed in 20 mL of 34 wt.% sulfuric acid solution a...

Embodiment 3

[0036] (1) Pre-carbonize HKUST-1(Cu) under an argon atmosphere at 600°C for 1 hour, wash with 1M hydrochloric acid to remove metal components, wash with water until neutral and dry at 65°C to obtain pre-carbonized porous carbon powder end;

[0037] (2) Add 0.1 g of pre-carbonized porous carbon powder into 10 mL of aqueous solution dissolved with 0.9 mmol of cobalt nitrate, stir at room temperature for 12 hours, evaporate the water to dryness at 50 °C with a rotary evaporator, and dry the obtained solid sample After grinding, heat treatment at 1000°C for 1 hour under an argon atmosphere, and then hydrothermally treat the resulting product with a mixture of 10M hydrochloric acid and 1.25wt.% hydrogen peroxide at 120°C for 24 hours, then wash with water until neutral, and then vacuum-dry at 60°C. Obtain graphitized porous carbon;

[0038] (3) Place 0.1 g of the above-mentioned graphitized porous carbon in 25 mL of 34 wt.% sulfuric acid solution and soak for 8 hours, then centrif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com