Mesoporous X-type molecular sieve, adsorbent based on molecular sieve, and preparation and application thereof

A molecular sieve and adsorbent technology, applied in the field of molecular sieve preparation and application, can solve the problems of low adsorption capacity, rate and desorption rate, and achieve the effects of high adsorption capacity, good adsorption selectivity, and increased transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method of mesoporous X-type molecular sieve, comprising the following steps:

[0039] a. Add the templating agent dropwise to the silicon source aqueous solution, and stir evenly at 25-35°C;

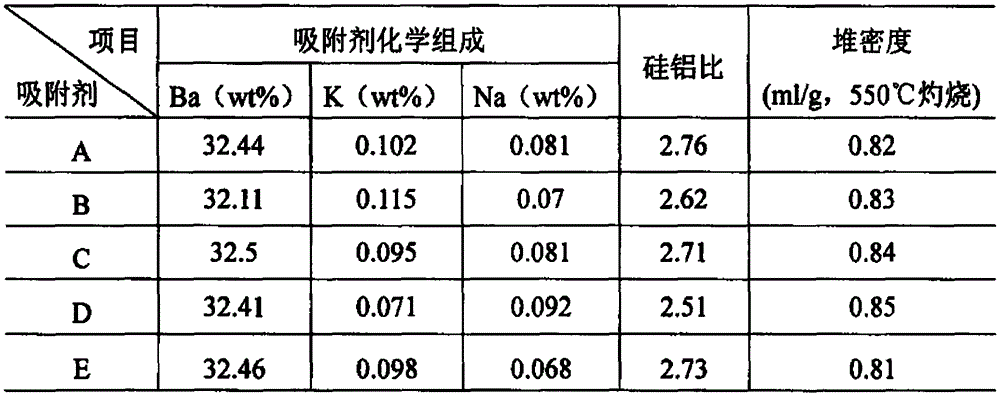

[0040] b. Add the solution obtained in step a dropwise to the aluminum source aqueous solution, and add a certain amount of sodium hydroxide solution so that the molar ratio thereof is SiO 2 : Al 2 o 3 :Na 2 O:H 2 O=(2.5~5): 1:(3~7.5):(180~300), the addition of template agent is 0.0001~5% of the total mass of the total reaction mixture, and continue stirring at 25~35°C to obtain a white gel ;

[0041] c. Transfer the white gel obtained in step b to the reactor for crystallization, the crystallization temperature is 80-180°C, preferably 100-150°C, the crystallization time is 24-120 hours, preferably 36-90 hours, and crystallize Then take it out and wash until the pH is 7-8. After drying, roast it at a temperature of 350-850°C, preferably 450-700°C. The roasting ...

Embodiment 1

[0055] Add 15 grams of aqueous solution of silane coupling agent (KH550) to 400 grams of water glass, add 150 grams of water, stir at 30°C until the solution is clear, and slowly add this clear solution dropwise to 250 grams of sodium metaaluminate solution (hydrogen Alumina was dissolved in sodium hydroxide solution), stirred at 30°C for 1 hour to obtain a white gel, which was transferred to a polytetrafluoroethylene-lined stainless steel reaction kettle, crystallized at 120°C for 72 hours, and the product was taken out. After cooling to room temperature, filter, take the solid product and wash it with deionized water until the pH is about 8, then dry it at 100°C, and roast the dried solid at 550°C for 4 hours to obtain the original powder ZA of mesoporous X-type molecular sieve. The particle size is 0.9-1.1 μm.

Embodiment 2

[0057] Add 20 grams of an aqueous solution of silane coupling agent (KH560) to 350 grams of silica sol solution, add 150 grams of water, stir at 35°C until the solution is clear, and slowly add it dropwise to 200 grams of sodium metaaluminate solution (to be (obtained by dissolving boehmite in sodium hydroxide solution), stirring at 30°C for 1 hour to obtain a white gel, which was transferred to a polytetrafluoroethylene-lined stainless steel reactor, crystallized at 150°C for 48 hours, and the product was taken out , after cooling to room temperature, filter, take the solid product and wash it with deionized water until the washing liquid is neutral, dry at 100°C, and roast the dried solid at 550°C for 4 hours to obtain the original powder of mesoporous X-type molecular sieve ZB, the particle size is 0.9-1.1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com