Up-conversion fluorescent molecular imprinted polymer and preparation method thereof

A fluorescent molecular imprinting and molecular imprinting technology, which is applied in chemical instruments and methods, luminescent materials, and other chemical processes, can solve problems such as strong toxicity, biological tissue damage, and background interference, and achieve fast mass transfer and high selectivity. Sexuality and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

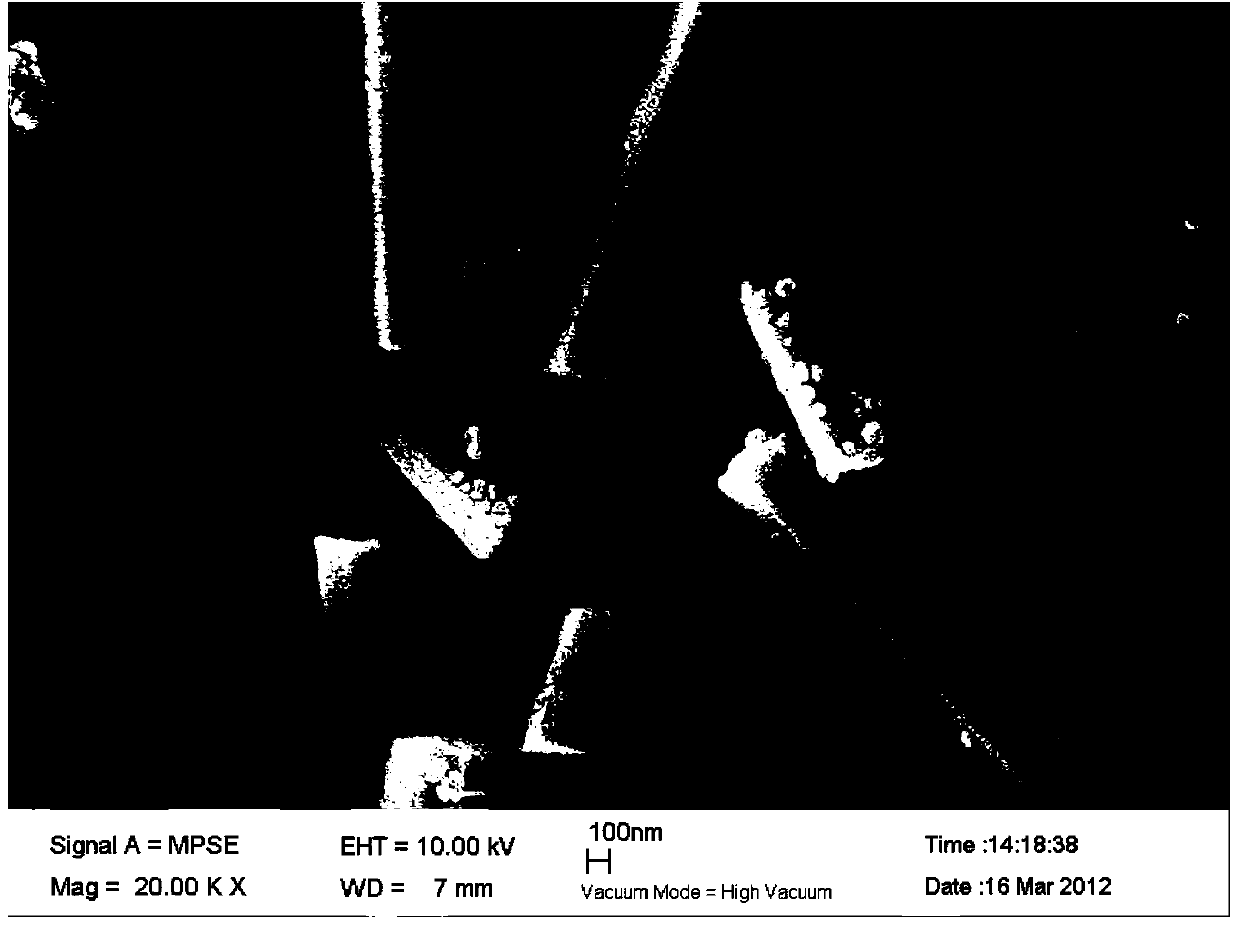

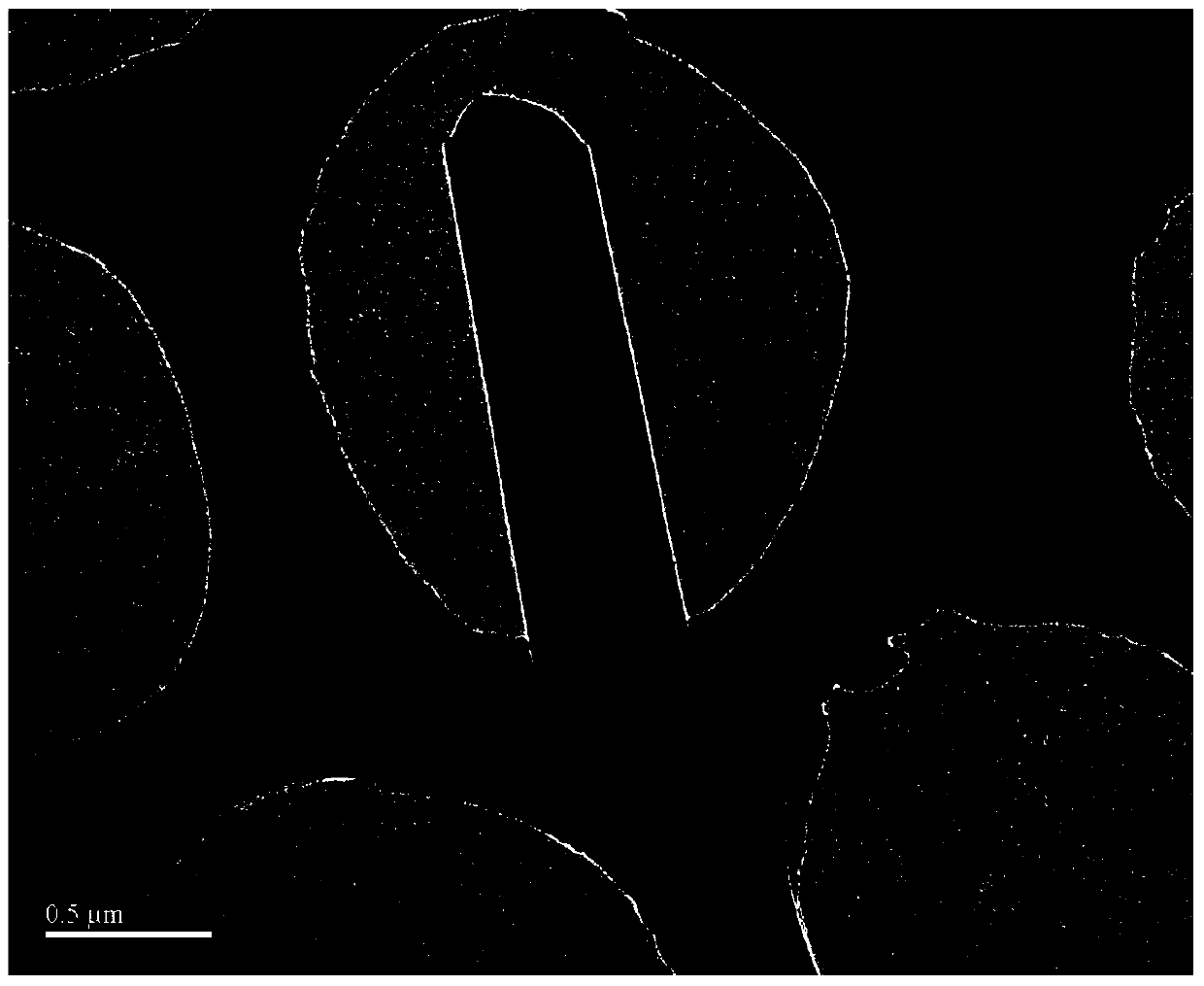

[0027] A method for preparing up-converting fluorescent molecularly imprinted polymers, comprising the following preparation steps:

[0028] (1) First add 0.250g up-conversion fluorescent nanorod β-NaYF 4 :Yb 3+ ,Er 3+ , then add solvent 2.0mL tetrahydrofuran and 2.0mL toluene and 0.165g amecarb template, stir well to dissolve it completely, then add 0.340mL (4.0mmol) methacrylic acid, stir well for 1h; add crosslinking agent ethylene glycol di Reaction of 0.760mL (4.0mmol) of methacrylate and 0.02g of initiator azobisisobutyronitrile for 0.5h; nitrogen gas flow for 10min, thermal polymerization in water bath at 60°C for 20h;

[0029] (2) The polymer in step (1) was pulverized, placed in a Soxhlet extractor, and 270 mL of methanol and 30 mL of glacial acetic acid were added as extraction solvents, and the extraction continued for 48 hours until no memethocarb was detected in the extract. Vacuum-dry at 60°C for 10 hours, and dimethocarb upconverts the fluorescent molecularly...

Embodiment 2

[0031] A method for preparing up-converting fluorescent molecularly imprinted polymers, comprising the following preparation steps:

[0032] (1) First add 0.330g up-conversion fluorescent nanorod β-NaYF 4 :Yb 3+ ,Er 3+ , then add solvent 1.0mL tetrahydrofuran and 2.0mL toluene and 0.165g amethyrcarb template, stir well to dissolve completely, then add 0.255mL methacrylic acid, stir well for 2h; add crosslinking agent ethylene glycol dimethacrylate React 0.570mL with 0.02g initiator azobisisobutyronitrile for 0.3h; blow nitrogen gas for 5min, heat polymerize in a water bath at 55°C for 18h;

[0033] (2) The polymer in step (1) was pulverized, placed in a Soxhlet extractor, and 270 mL of methanol and 30 mL of glacial acetic acid were added as extraction solvents, and the extraction continued for 40 hours until no amecarb was detected in the extract. Vacuum-dry at 50°C for 8 hours, and dimethocarb upconverts the fluorescent molecularly imprinted polymer.

Embodiment 3

[0035] A method for preparing up-converting fluorescent molecularly imprinted polymers, comprising the following preparation steps:

[0036] (1) First add 0.206g up-conversion fluorescent nanorod β-NaYF 4 :Yb 3+ ,Er 3+ , then add solvent 2.0mL tetrahydrofuran and 1.0mL toluene and 0.165g amecarb template, stir well to dissolve completely, then add 0.300mL methacrylic acid, stir well for 1.5h; add crosslinking agent ethylene glycol dimethacrylic acid Reaction of 1.880mL of ester and 0.02g of initiator azobisisobutyronitrile for 0.4h; nitrogen gas flow for 8min, thermal polymerization in water bath at 57℃ for 22h;

[0037] (2) The polymer in step (1) was pulverized, placed in a Soxhlet extractor, and 270 mL of methanol and 30 mL of glacial acetic acid were added as extraction solvents, and the extraction was continued for 42 hours until no amecarb was detected in the extract. Vacuum-dry at 55°C for 9 hours, and dimethocarb upconverts the fluorescent molecularly imprinted poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com