Composite material of nitrogen doped three-dimensional graphene supported nano silver and preparation method thereof

A composite material, graphene technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of reducing the excellent properties of graphene, prone to stacking and agglomeration, and achieve easy reaction process. Control, catalytic activity enhancement, and spin density enhancement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Preparation of graphene materials:

[0021] With graphite paper as anode, carbon rod as cathode, and concentrated sulfuric acid (concentration 98%) as electrolyte, the graphite paper is oxidized and peeled off at a constant current of 0.2A; after 24 hours of peeling, the electrolyte is diluted 10 times with distilled water, and the solution is After cooling to room temperature, use a high-speed centrifuge at 12,000 rpm to separate and filter. The filtered powder was fully washed with distilled water to neutrality, and dried at 50° C. under a vacuum of 100 Pa to obtain graphene oxide powder.

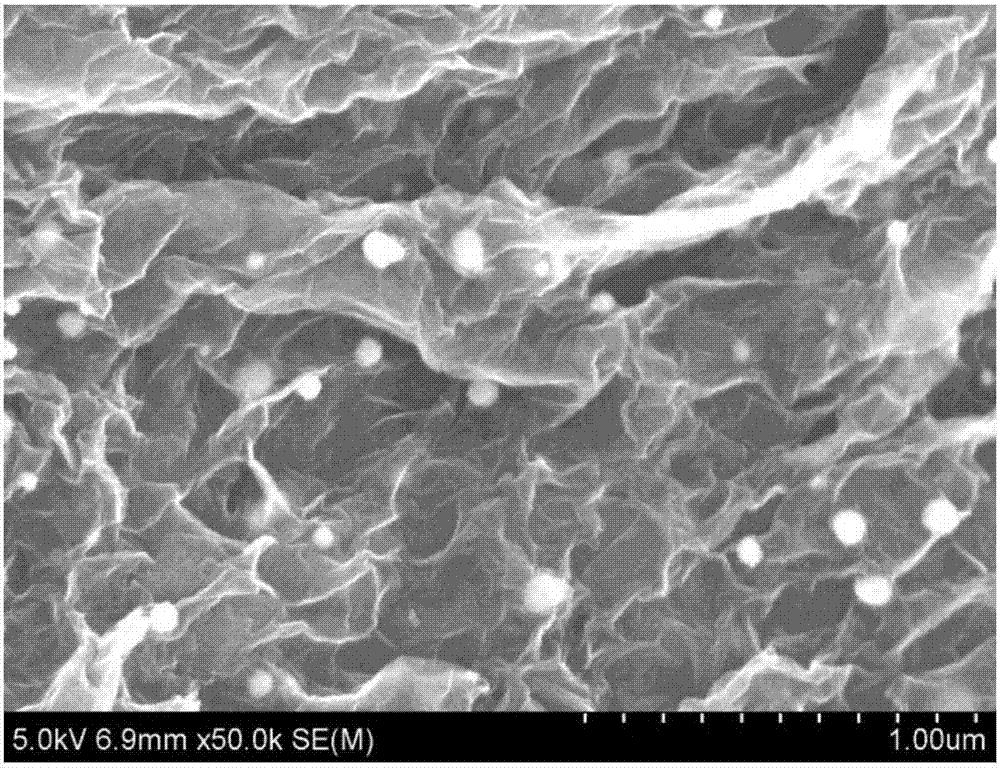

[0022] 2. Preparation of nitrogen-doped three-dimensional graphene-supported nano-silver composite:

[0023] Add 200 mg of the above graphene oxide powder into 100 mL of distilled water, and make a suspension after ultrasonic dispersion for 60 minutes; add 20 mL of ethylenediamine solution into the graphene oxide suspension, ultrasonically disperse for 10 minutes, then weigh 42...

Embodiment 2

[0026] 1. Preparation of graphene materials:

[0027] Using graphite paper as anode, carbon rod as cathode, and concentrated sulfuric acid (98% concentration) as electrolyte, the graphite paper is oxidized and peeled off at a constant current of 0.2A. After stripping for 24 hours, the electrolyte solution was diluted 10 times with distilled water, and after the solution was cooled to room temperature, it was separated and filtered by a high-speed centrifuge at 12,000 rpm. The filtered powder was fully washed with distilled water to neutrality, and dried at 50° C. under a vacuum of 100 Pa to obtain graphene oxide powder.

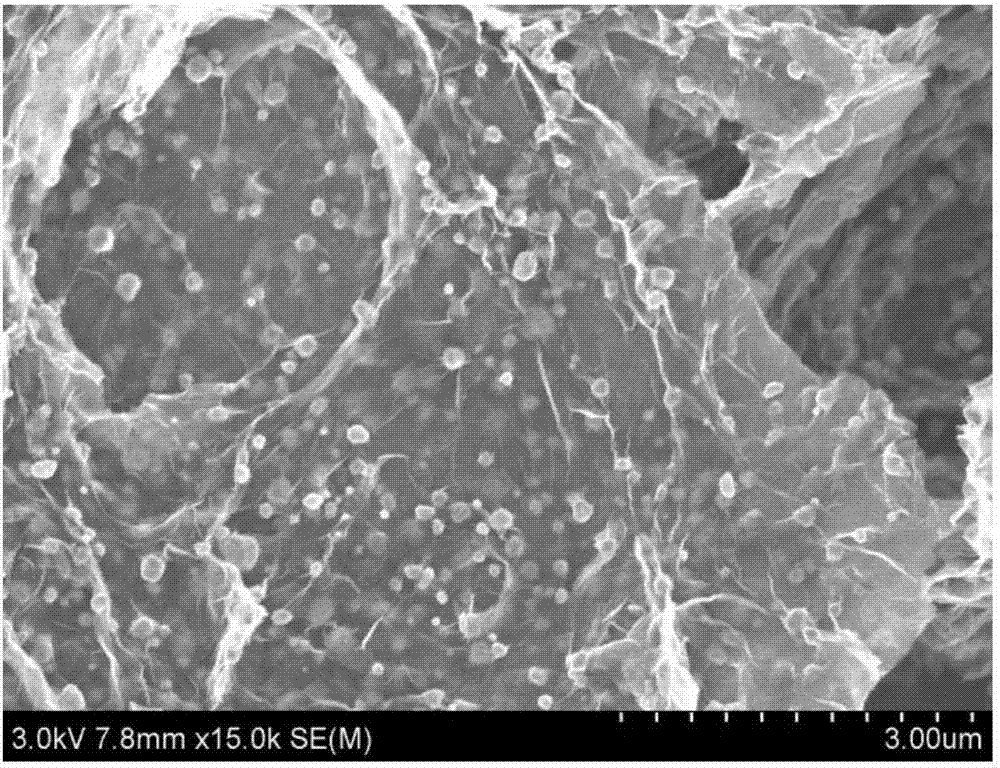

[0028] 2. Preparation of nitrogen-doped three-dimensional graphene-loaded nano-silver composite:

[0029] Take 100 mg of the above-mentioned graphene oxide powder and add it into 100 mL of distilled water, and make a suspension after ultrasonic dispersion for 60 min. Take 10mL of ethylenediamine solution and add it to the graphene oxide suspension, ultrason...

Embodiment 3

[0032] 1. Preparation of graphene materials:

[0033] Using graphite paper as anode, carbon rod as cathode, and concentrated sulfuric acid (98% concentration) as electrolyte, the graphite paper is oxidized and peeled off at a constant current of 0.2A. After stripping for 24 hours, the electrolyte solution was diluted 10 times with distilled water, and after the solution was cooled to room temperature, it was separated and filtered by a high-speed centrifuge at 12,000 rpm. The filtered powder was fully washed with distilled water to neutrality, and dried at 50° C. under a vacuum of 100 Pa to obtain graphene oxide powder.

[0034] 2. Preparation of nitrogen-doped three-dimensional graphene-supported nano-silver composite:

[0035] Take 120 mg of the above-mentioned graphene oxide powder and add it to 100 mL of distilled water, and make a suspension after ultrasonic dispersion for 60 minutes; take 15 mL of ethylenediamine solution and add it to the graphene oxide suspension, ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com