Multifunctional high-efficiency aerator and using method thereof

An aerator and multi-functional technology, applied in chemical instruments and methods, water aeration, sustainable biological treatment, etc., can solve problems such as aeration dead zone, achieve the elimination of air bubbles, lower cost, and high mass transfer rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

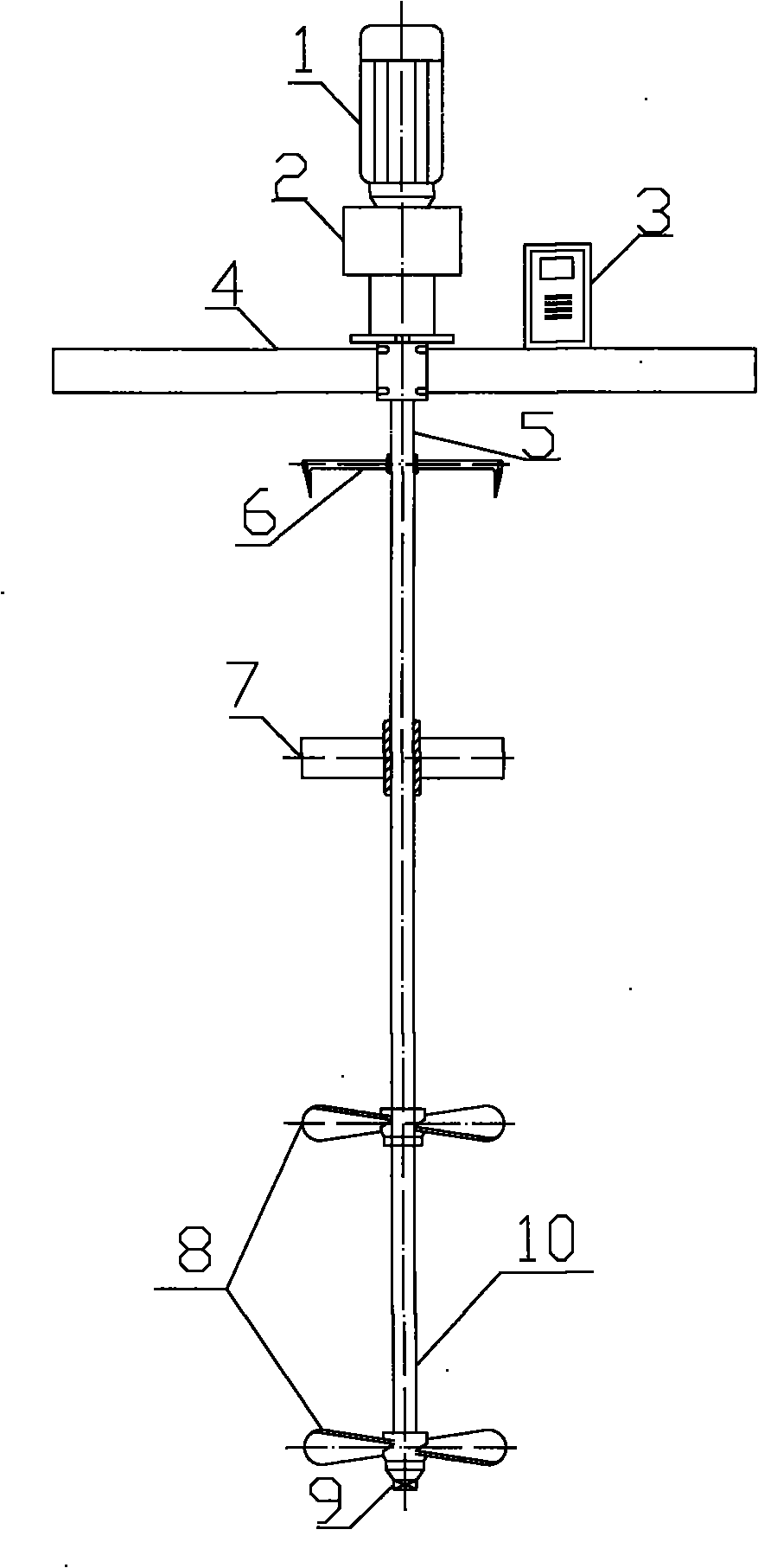

Method used

Image

Examples

Embodiment 1

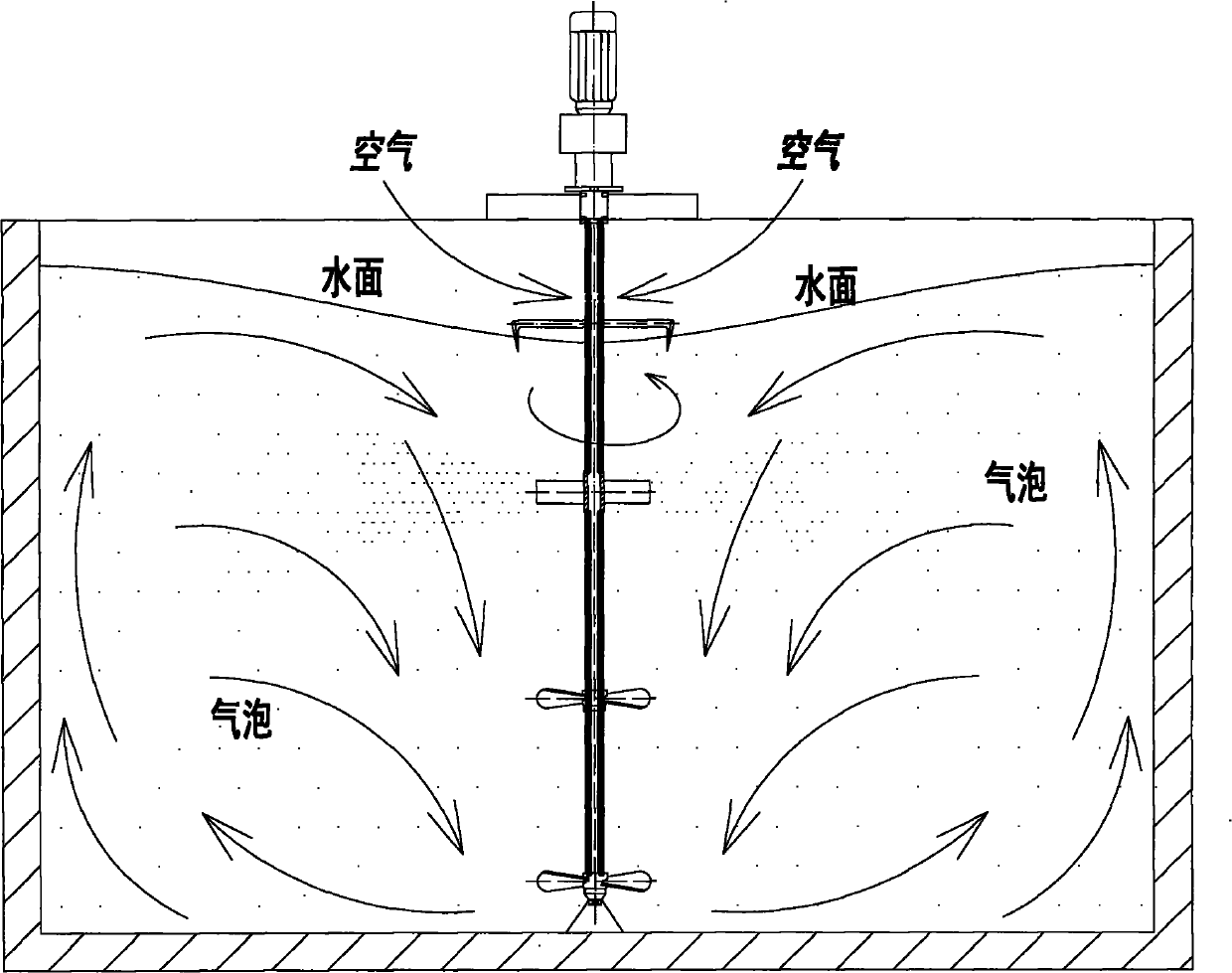

[0017] Embodiment 1: when needing aeration, start motor 1, drive hollow shaft 10 and the impeller on the shaft to rotate, when air-breathing turbine 7 reaches critical speed (200-450r / min), produces enough big near air-breathing turbine 7 Negative pressure, a large amount of air is sucked in through the air hole 5 on the hollow shaft 10, and is ejected from the air outlet hole between the suction turbine 7 through the hollow shaft 10, under the action of the shear force and dynamic pressure change force near the suction turbine 7 , produce very small micro-bubbles, greatly increasing the specific surface area of the bubbles. The defoaming paddle 6 can chop the foam on the water surface, and the upflow and downflow circulating in the pool make the liquid surface constantly updated, bringing the foam on the liquid surface to the bottom of the pool, and the foam is driven to change the local thickness of the bubble surface, while the water flow The pressure on the surface of th...

Embodiment 2

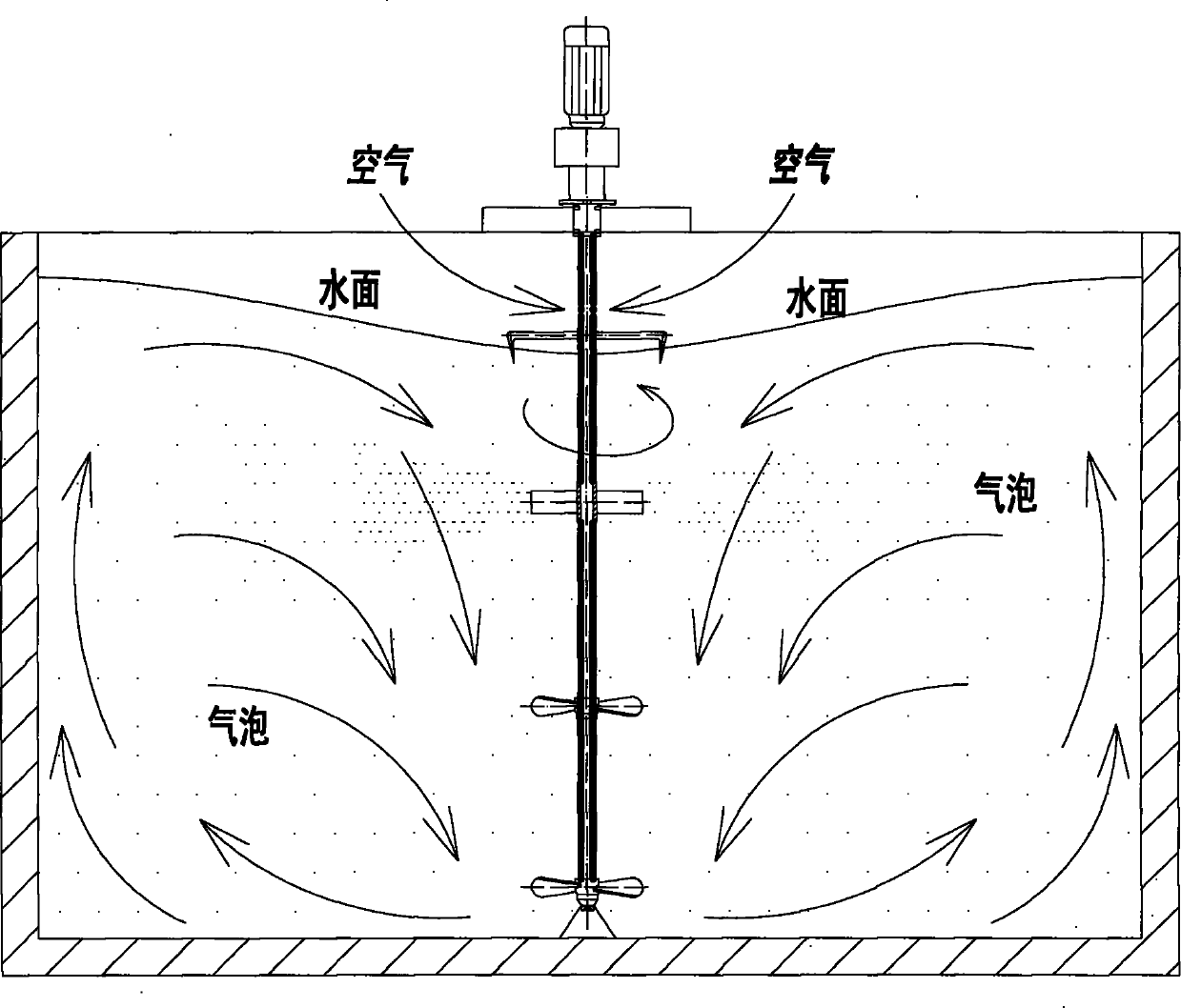

[0018] Example 2: When it is necessary to remove nitrogen and phosphorus from sewage, the sewage treatment process needs to be switched between aerobic, anoxic and anaerobic modes. Start the motor 1 to drive the hollow shaft 10 and the impeller on the shaft to rotate. When the suction turbine 7 reaches the critical speed (200-450r / min), a large enough negative pressure will be generated near the suction turbine 7, and the air will flow from the hollow shaft 10 A large amount of air holes 5 in the air are inhaled, and are ejected from the air outlet holes between the air-intake turbines 7 through the hollow shaft 10. Under the action of the shear force and dynamic pressure change force near the air-intake turbine 7, very small micro-bubbles are generated, which greatly increases the The specific surface area of the bubbles. The defoaming paddle 6 can chop the foam on the water surface, and the upflow and downflow circulating in the pool make the liquid surface constantly upda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com