Isolating layer used for lithium-sulfur battery

A lithium-sulfur battery and interlayer technology, which is applied to battery components, circuits, electrical components, etc., to achieve the effects of reducing battery internal resistance, improving cycle and rate performance, and improving ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

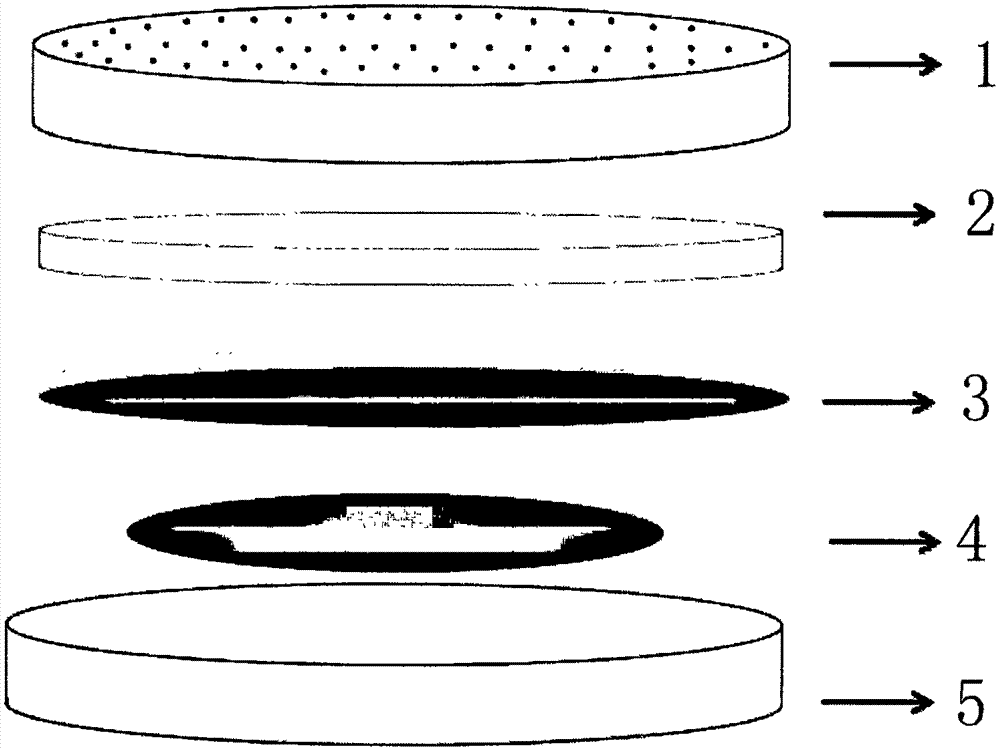

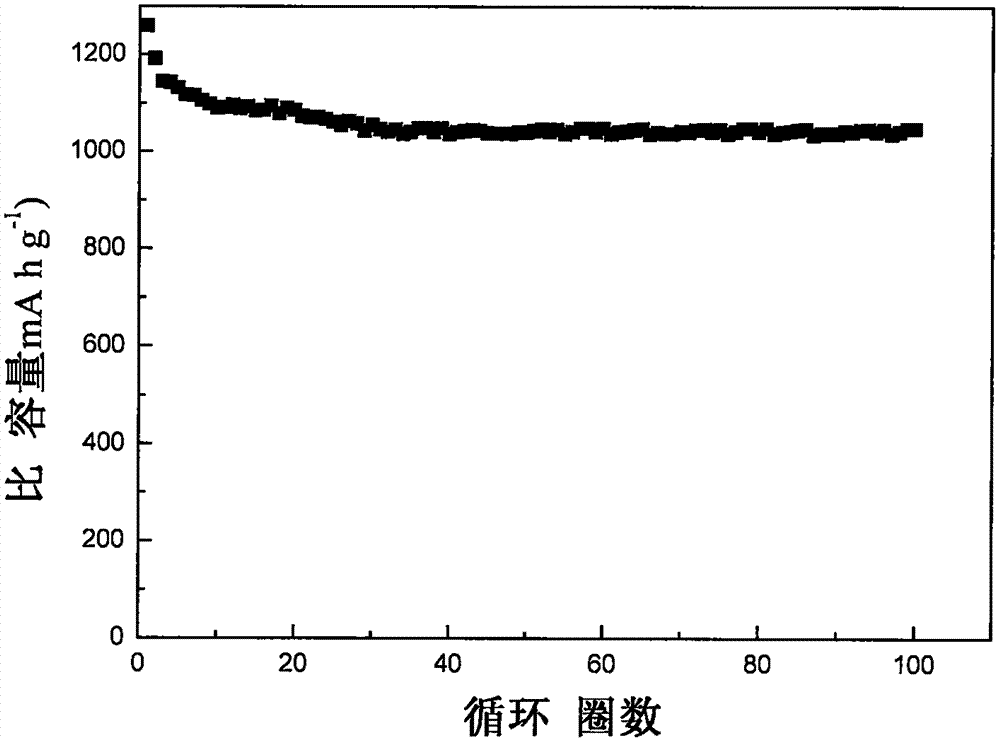

[0014] Add 0.4g of sulfonic acid lithiated multi-walled carbon nanotubes, 0.05g of acetylene black, 0.05g of LA132 binder, 2g of isopropanol and water in a volume ratio of 1:3 to prepare a mixed solution, stir at room temperature for 24 hours Finally, it was evenly coated on the polypropylene separator with a film applicator, dried naturally to form a protective interlayer, and then assembled into a lithium-sulfur battery according to the way that the interlayer was attached to the positive electrode for electrochemical performance testing. The battery structure is as follows: figure 1 shown. At 0.1C (1C=1675mA h g -1 ), the first discharge specific capacity of the battery assembled with the separator modified by sulfonate lithiation modified coating reached 1259mA h g -1 , the 100-cycle cycle capacity is stable at 1048mAhg -1 , the single-turn attenuation rate is about 0.15%, which is much lower than that of lithium-sulfur batteries (0.35%) with ordinary diaphragms, and its...

Embodiment 2

[0016] Add 0.4g of sulfonic acid lithiated graphene, 0.02g of Ketjen carbon, 0.08g of polytetrafluoroethylene, 2g of n-propanol and water in a volume ratio of 1:3 to prepare a mixed solution, stir at room temperature After 24 hours, it was evenly coated on the positive electrode sheet by spraying method, and formed a protective interlayer after drying, and then assembled into a lithium-sulfur battery according to the normal assembly method for electrochemical performance testing.

Embodiment 3

[0018] Add 0.3g of sulfonic acid lithiated activated carbon, 0.1g of alumina, 0.05g of Super P, 0.05g of gelatin, 2g of n-propanol and water in a volume ratio of 1:3 to prepare a mixed solution, stir at room temperature for 24 hours, In the glove box, it is evenly coated on the negative electrode lithium sheet by spraying method, after drying, a protective interlayer is formed, and then assembled into a lithium-sulfur battery according to the normal assembly method for electrochemical performance testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com