High-efficiency energy-saving lime kiln

A lime kiln, high-efficiency and energy-saving technology, applied in the kiln field, can solve the problems of unloading and uneven calcination, and achieve the effect of smooth ash discharge, convenient maintenance, and balanced ash discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

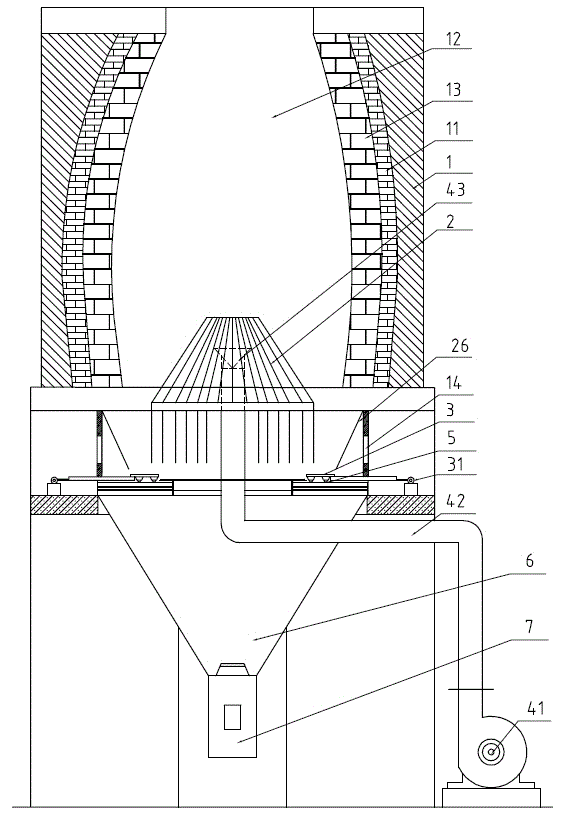

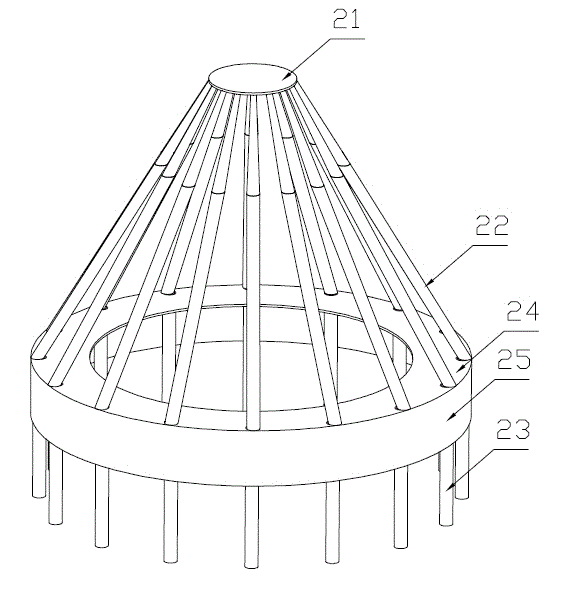

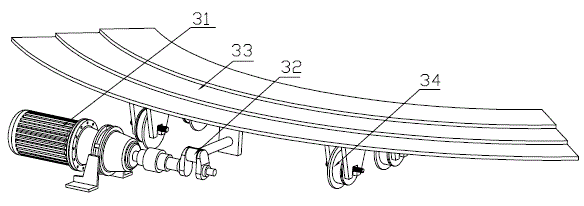

[0017] Such as Figure 1-3 As shown, a high-efficiency and energy-saving lime kiln includes a furnace body 1, a furnace 11, a main furnace grate 2, a side furnace grate 26, an ash unloading system and an air supply system. The slag and cement mixture layer 13 is covered with iron sheets. The top of the furnace body 1 is provided with a flue. 7. The main furnace grate 2 is fixed in the middle of the hearth 11, the upper part of the main furnace grate 2 is a conical structure, the upper part has a reinforcement ring 21, the middle part has a circular skeleton 24 and a grate support 25, the reinforcement ring 21 and the circular skeleton There are 22 cone-shaped furnaces evenly distributed between 24, and the lower part of the circular skeleton 24 is evenly and vertically provided with hanging fireplace bars 23, and the side grates 26 are fixed around the main furnace grate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com