MXene electromagnetic shielding fabric as well as preparation method and application thereof

An electromagnetic shielding and fabric technology, applied in textiles and papermaking, physical treatment, fiber treatment, etc., can solve the problems of poor durability and poor electromagnetic shielding effect, and achieve the improvement of wave absorption performance, protection of human health, and skin-friendly fabrics. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) The preparation process of MXene:

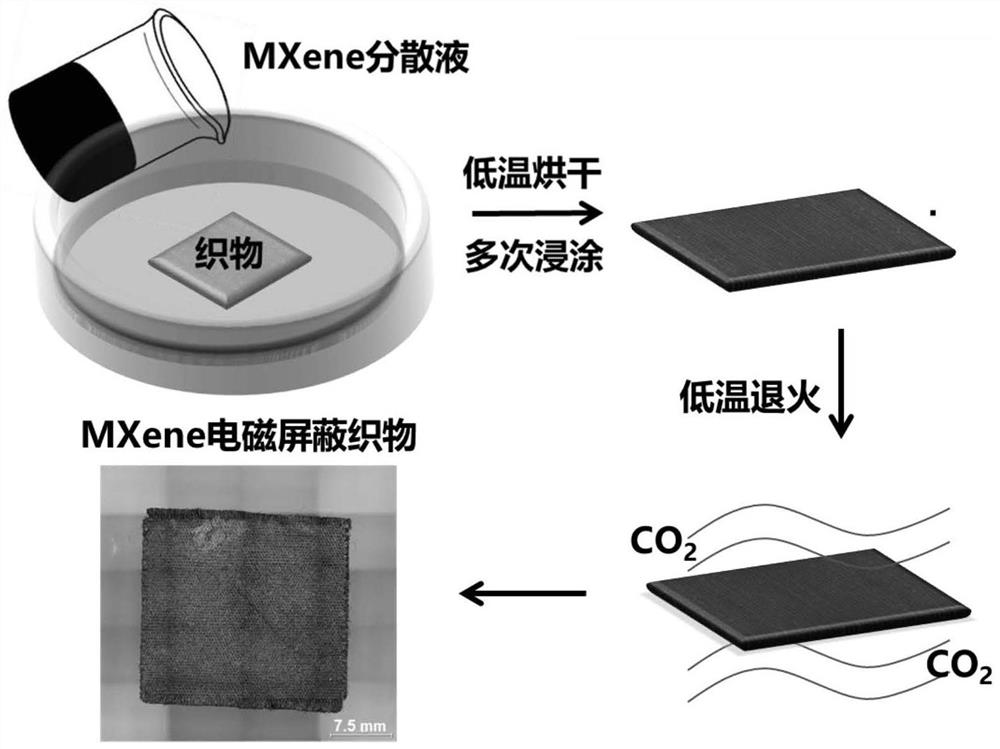

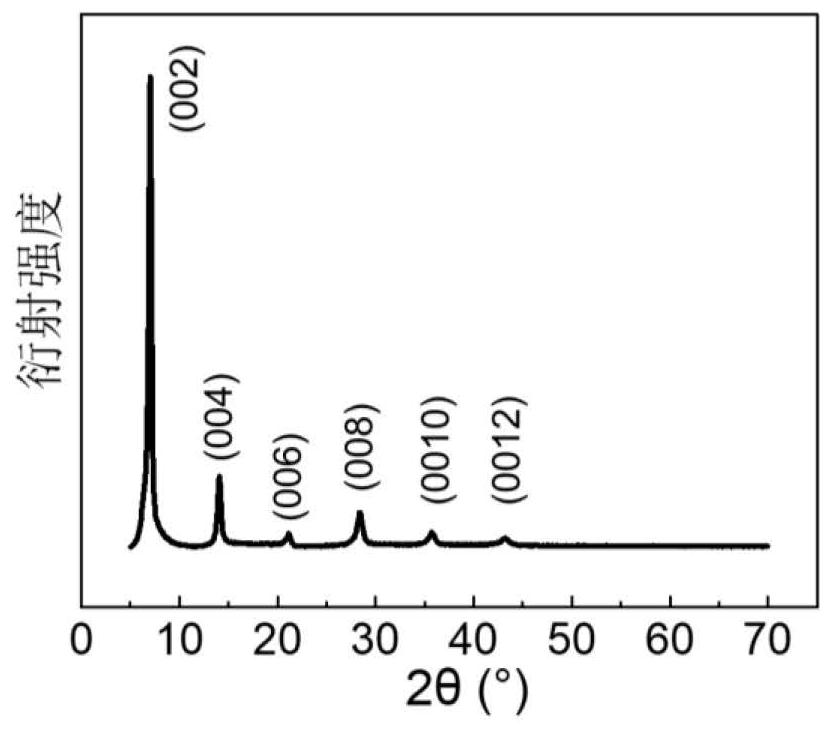

[0045] Fully stir the etching solution of 1.6g LiF, 19.25g HCl, and 5.5mL ultrapure water, and slowly add 1g MAX phase (Ti 3 AlC 2 ) powder, the reaction temperature is 27°C, the stirring rate is 700r / min, and the stirring is continued for 24h until the etching is complete. Centrifuge several times at 3500r / min for washing until the pH of the supernatant is close to 7. Then the obtained precipitate was fully dispersed in deionized water, centrifuged at 3500r / min for 5min to collect the upper black liquid, which was the MXene dispersion. figure 2 The XRD pattern of the MXene prepared in Example 1 shows that the MXene is completely etched.

[0046] (2) Fabric pretreatment:

[0047] Divide 2.5×2.5cm 2 Pure cotton cloth (thickness 2mm) is put into the plasma processor, and setting power is 60W, and processing time is 5min, in O 2 The pure cotton cloth is pretreated under the atmosphere.

[0048] (3) Put the pure cotton cloth p...

Embodiment 2

[0054] (1) The preparation process of MXene:

[0055] Fully stir the etching solution of 1g LiF, 12.5g HCl, and 5.5mL ultrapure water, and slowly add 1g MAX phase (Ti 3 AlC 2) powder, the reaction temperature is 25°C, the stirring rate is 650r / min, and the stirring is continued for 22h until the etching is complete. Wash by centrifugation several times at 3000r / min until the pH of the supernatant is close to 7. Then the obtained precipitate was fully dispersed in deionized water, centrifuged at 3000r / min for 3min to collect the upper black liquid, which was the MXene dispersion.

[0056] (2) Fabric pretreatment:

[0057] Divide 2.5×2.5cm 2 The pure linen (thickness 3mm) is put into the plasma processor, and the set power is 50W, and the processing time is 3min. 2 Pure sackcloth is pretreated under atmosphere.

[0058] (3) Put the pretreated pure sackcloth in the step (2) into the petri dish containing the 7.5mg / mLMXene / water dispersion obtained in the step (1), soak it f...

Embodiment 3

[0064] (1) The preparation process of MXene:

[0065] Fully stir the etching solution of 2g LiF, 30g HCl, and 5.5mL ultrapure water, and slowly add 1g MAX phase (Ti 3 AlC 2 ) powder, the reaction temperature is 30°C, the stirring speed is 750r / min, and the stirring is continued for 26h until the etching is complete. Centrifuge several times at 4000r / min to wash until the pH of the supernatant is close to 7. Then the obtained precipitate was fully dispersed in deionized water, centrifuged at 4000r / min for 8min to collect the upper black liquid, which was the MXene dispersion.

[0066] (2) Fabric pretreatment:

[0067] Divide 2.5×2.5cm 2 Bamboo fiber cloth (thickness 4mm) is put into the plasma processor, and setting use power is 70W, and processing time is 8min, and in O 2 Bamboo fiber cloth is pretreated under atmosphere.

[0068] (3) Put the pretreated bamboo fiber cloth in step (2) into the petri dish containing the 10mg / mL MXene / water dispersion obtained in step (1), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com