Device and process method for preparing light calcined magnesia by suspension calcination

A kind of light burning magnesia, suspension calcining technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

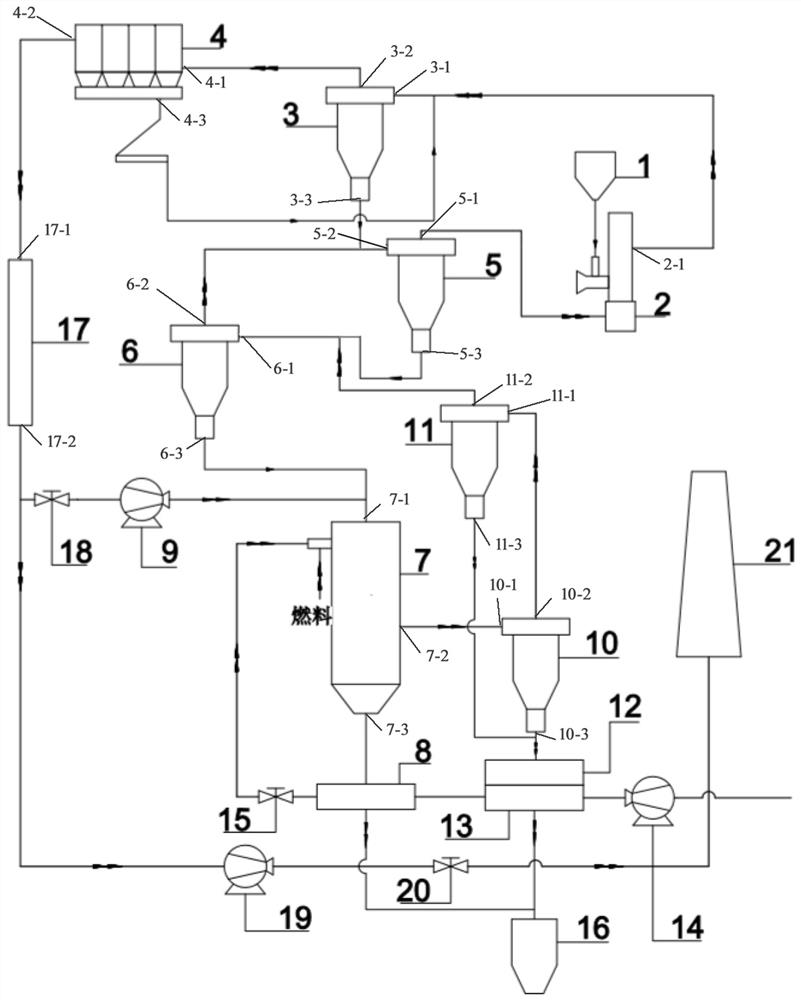

[0090] The feeding port of the raw material bin 1 is connected with the feeding port of the flash dryer 2 through the conveying equipment (existing screw feeder and other equipment with conveying function); the air inlet of the flash dryer 2 is connected with the secondary preheating cyclone 5 The gas outlet Ⅲ5-1 of the flash dryer 2 is connected, and the gas outlet Ⅰ2-1 of the flash dryer 2 is connected with the gas inlet Ⅰ3-1 of the first-stage preheating cyclone 3; the gas outlet Ⅰ3-2 of the first-stage preheating cyclone 3 It communicates with the gas inlet Ⅰ 4-1 of the bag filter 4, and the material outlet Ⅰ 3-3 of the primary preheating cyclone 3 is connected with the gas material inlet Ⅱ 5-2 of the secondary preheating cyclone 5; the gas outlet Ⅱ 4-2 of the bag filter 4 It is connected with the gas inlet II17-1 of the waste gas treatment device 17, and the material outlet II4-3 of the bag filter 4 is connected with the gas material inlet I3-1 of the primary preheating cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com