Method for preparing building gypsum by desulfurized gypsum and device of building gypsum

A technology for desulfurization gypsum and building gypsum, which is applied in the field of comprehensive treatment technology of desulfurization gypsum, can solve the problems of inability to change the internal crystal structure, affecting the quality of building gypsum, easily under-burning or over-burning, etc., so as to improve the processing performance and products. Performance, good strength, long residence time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

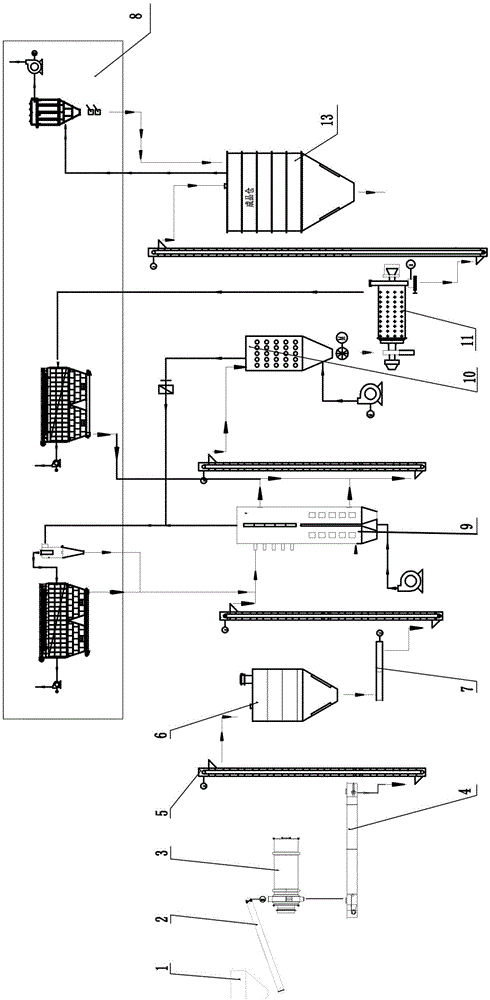

Image

Examples

Embodiment Construction

[0025] The concrete processing step that the present invention adopts is as follows:

[0026] Dry the desulfurized gypsum raw material with hot air, the drying temperature is controlled between 110-130°C, and the attached water content after drying is ≤3%;

[0027] The dried gypsum is calcined, the calcining temperature is between 150-160°C, and the calcining time is 20-40min;

[0028] Lower the temperature of the calcined gypsum to 50-60°C,

[0029] The cooled material is sent to a ball mill for grinding, and the particle size of the material after grinding is above 200 mesh.

[0030] Adopt various equipment among the present invention to carry out the process of manufacturing:

[0031] Firstly, the raw materials will be dried. By comparing various drying equipment, it is found that the tumble dryer is more suitable for the drying of the raw materials in the present invention, because the main components of the raw materials in the present invention are mainly calcium sulfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com