Saggar and method for producing abrasive material through saggar

A sagger and abrasive technology, applied in the field of superhard materials, can solve the problems of deformation and cracking of sagger, affect the stability of abrasive quality, and high cost, so as to improve hydrophilicity and grinding performance, improve appearance and grinding ability, The effect of reducing the content of magnetic substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

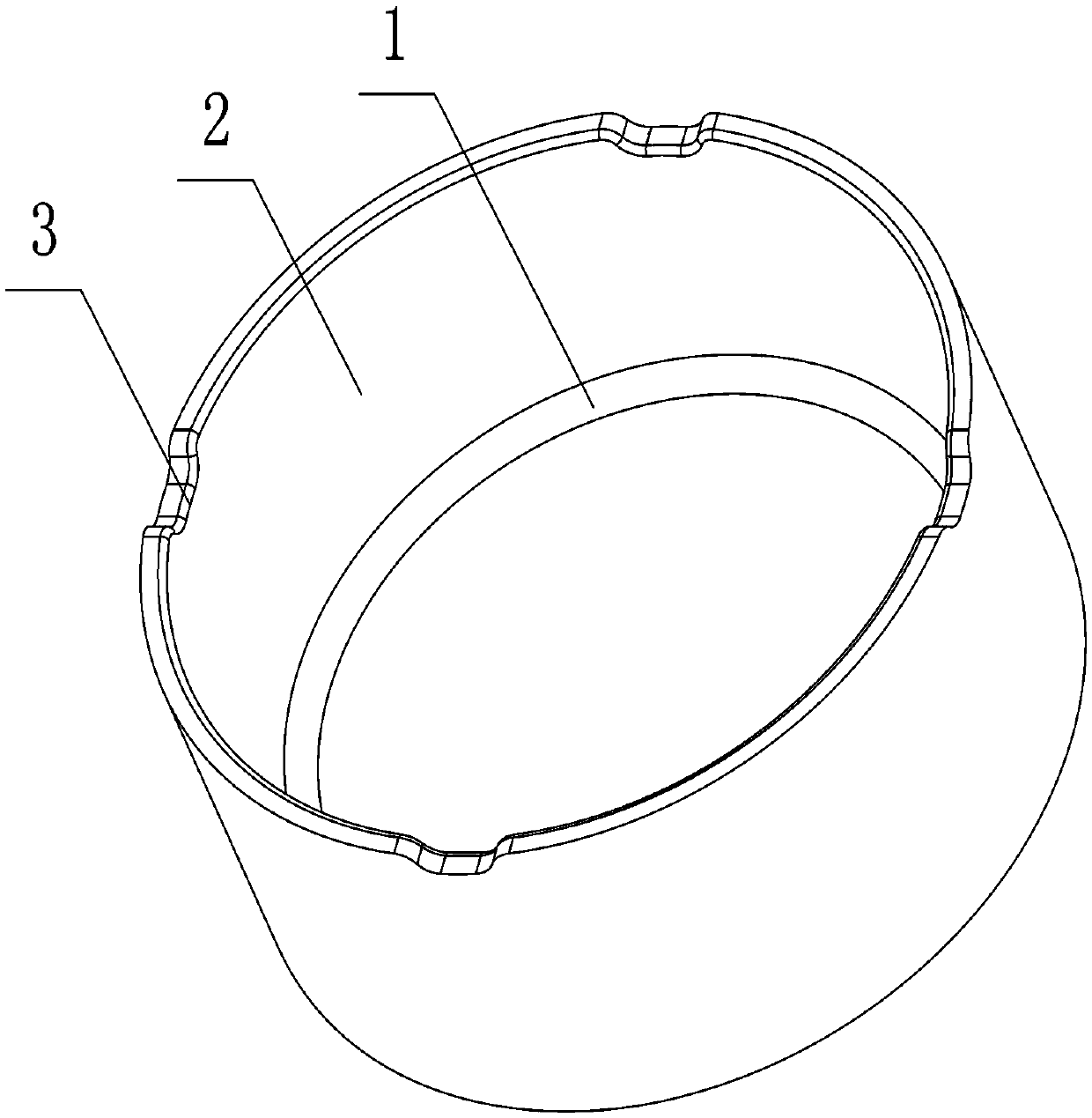

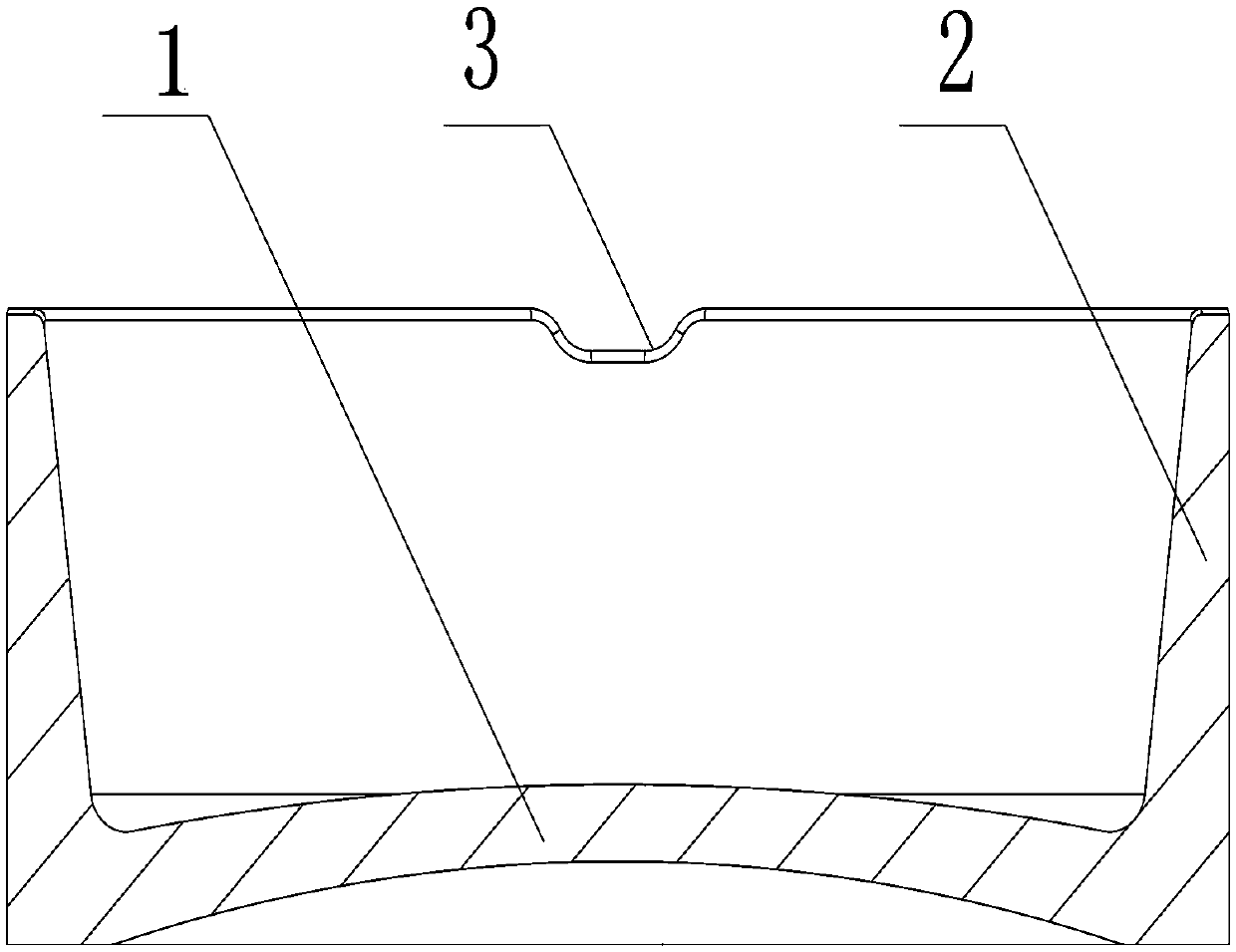

[0026] The present embodiment provides a kind of sagger, such as figure 1 As shown, the sagger includes a circular saggar base 1 and a cylindrical sagger wall 2, the cylindrical sagger wall is thin at the top and thick at the bottom, and four U-shaped ventilation holes 3 are evenly distributed on the top, and the ventilation holes 3 are uniformly distributed on the top of the sagger. The pores 3 ensure the heat convection inside and outside the sagger, so that the material is heated more evenly during the calcination process. Such as figure 2 As shown, the base of the circular sagger is an upward spherical groove. This structure enhances the anti-deformation performance of the sagger at high temperature and ensures the heat exchange of the material during high-temperature calcination. At the same time, the sagger can be reused many times, which reduces the production cost.

[0027] The present embodiment also provides a method for producing abrasive materials using the abov...

Embodiment 2

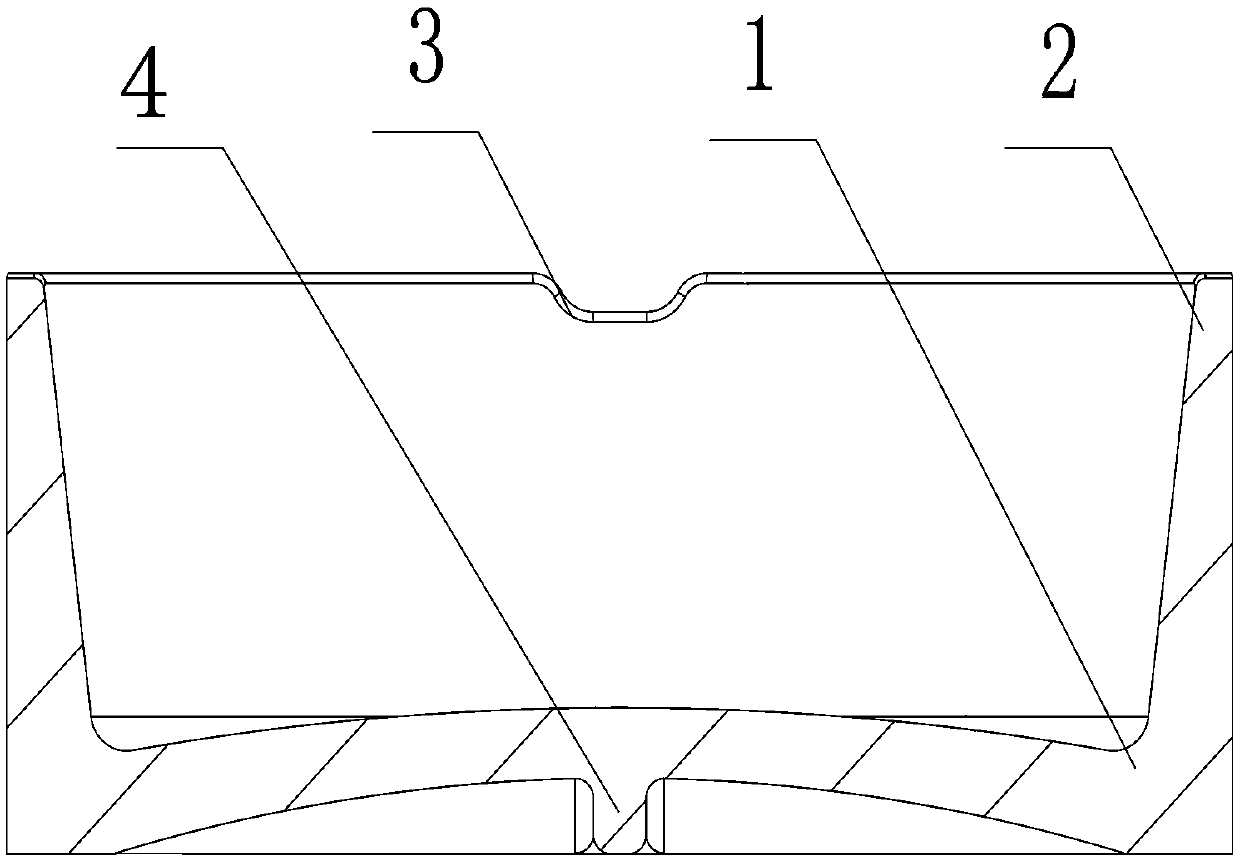

[0031] This embodiment provides a sagger, the structure of the sagger is roughly the same as that in Embodiment 1, the difference is that a layer of corundum reinforcing layer is attached to the surface of the sagger provided in this embodiment; The outer bottom of the spherical groove of the sagger base 1 is also provided with a cross-shaped reinforcing rib 4 that is flush with the sagger base 1, as image 3 with Figure 4 shown. The reserved space formed by the cross-shaped reinforcing rib 4 and the spherical groove ensures the heat and gas exchange of the materials in the upper and lower saggers, and at the same time, the cross-shaped reinforcing rib 4 strengthens the shape of the spherical surface. The strength of the shaped sagger base 1 makes the sagger still have strong deformation and crack resistance after high and low temperature calcination temperature cycles.

[0032] This embodiment also provides a method for producing abrasives using the sagger provided in this...

Embodiment 3

[0034] This embodiment provides a sagger, and the structure of the sagger is roughly the same as that of the sagger in Embodiment 1, the difference is that the outer bottom of the groove located at the sagger base 1 provided in this embodiment is also uniform. The cloth has two strip-shaped reinforcing ribs 4, such as Figure 5 with Image 6 shown.

[0035] This embodiment also provides a method for producing abrasives using the saggar provided in this embodiment. The specific steps are roughly the same as in Embodiment 1, except that in the first step, the upper and lower layers are adjacent to each other. The weight ratio of the abrasive in the sagger is 5:3; the heating rate in the second step is 200°C / h, the calcination temperature is 1200°C, and the calcination time is 2.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com