Machine-made charcoal charring and decoking technology and apparatus thereof

A technology of mechanism carbonization and carbonization, which is used in stationary carbonization furnaces, coke ovens, petroleum industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A mechanism carbonization decoking process, comprising the following steps

[0016] S1) carbonization, carbonizing the biomass raw material in a carbonization furnace;

[0017] S2) Coarse decoking, the wood gas produced in the carbonization process is mixed with impurities, smoke, etc., and part of the smoke and tar are filtered through this step;

[0018] S3) High-voltage electrostatic decoking. The function of the electrostatic decoking device is to use the effect of a strong electric field to make the fine particles such as dust and oil mist in the semi-water gas negatively charged and move to the cathode. After neutralization, they are adsorbed, precipitated and discharged. To achieve the purpose of removal, remove most of the smoke and tar;

[0019] S4) liquid phase separation;

[0020] S5) Activated carbon purification, absorbing residual impurities by activated carbon;

[0021] S6) supercharging, easy to collect after supercharging;

[0022] The process flow ...

Embodiment 2

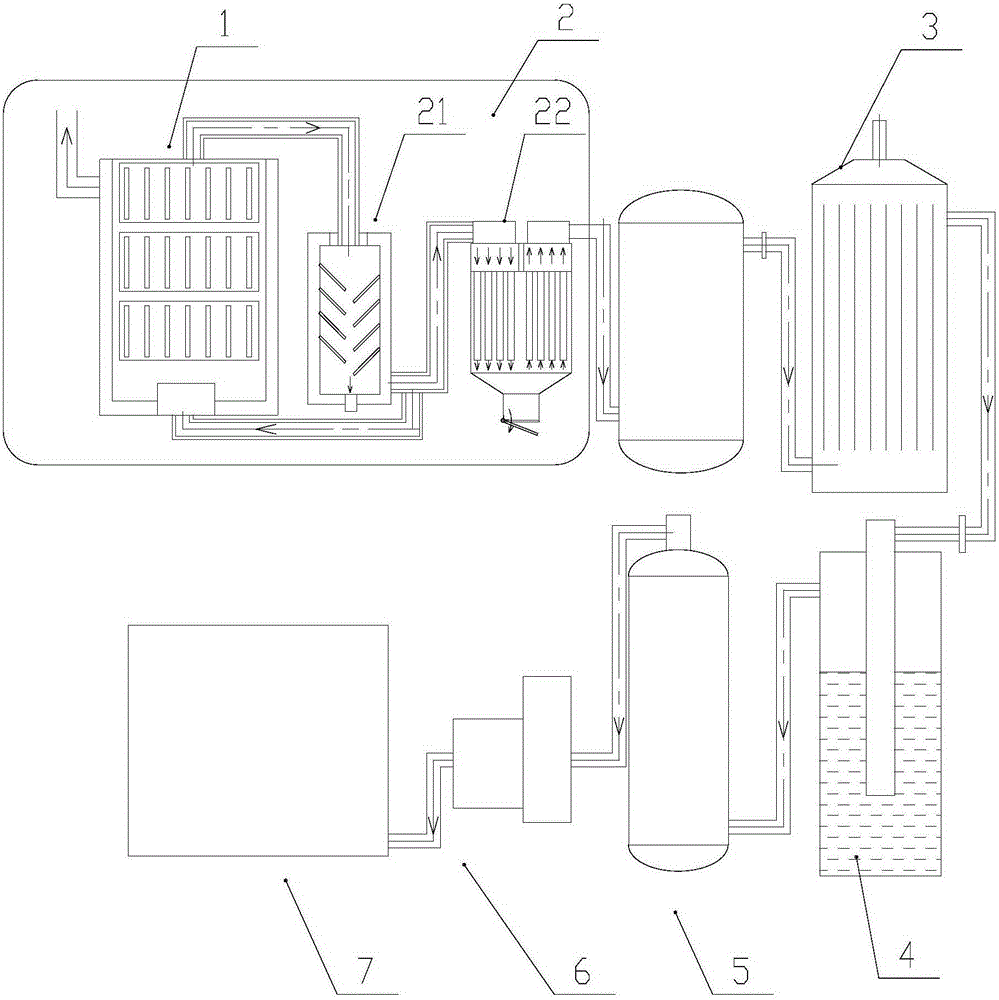

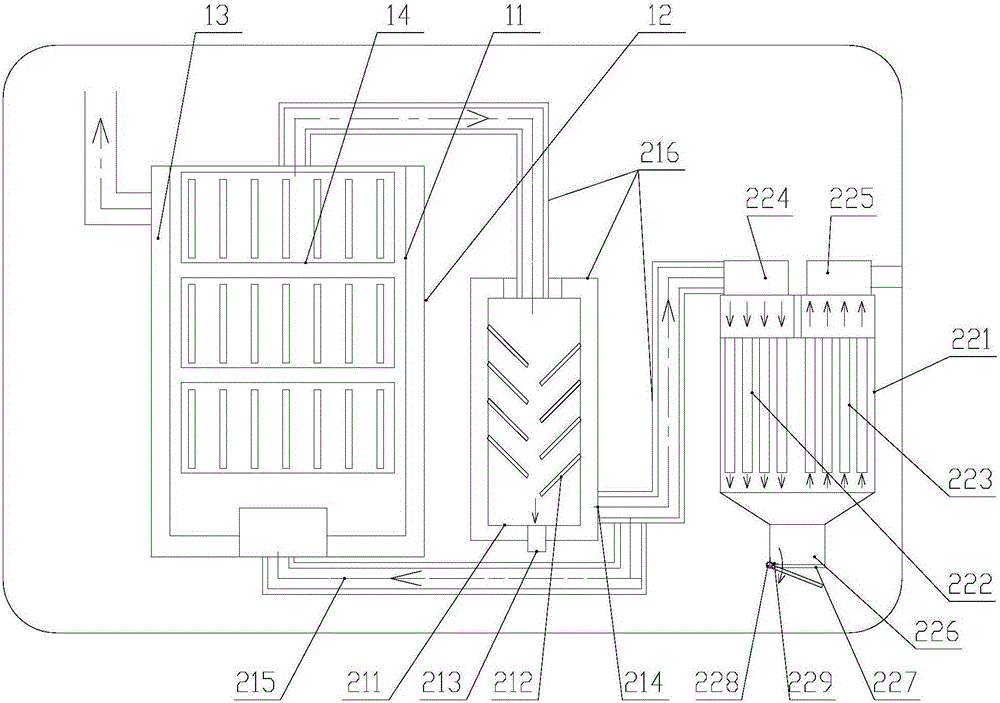

[0024] A mechanical carbonization and decoking device, including a carbonization furnace 1, a rough decoking device 2, a high-voltage electrostatic decoking tower 3, a liquid phase separator 4, an activated carbon purification tower 5, a compressor 6 and a gas storage tank connected sequentially through pipelines 7. Biomass raw materials such as powder or bars made of powder are carbonized in the carbonization furnace 1, and the flue gas generated during the carbonization process passes through the coarse decoking device 2 for coarse dedusting and decoking, and the high-voltage electrostatic decoking tower 3 for fine dedusting and decoking , the liquid phase separator 4 separates the liquid, the activated carbon purification tower 5 absorbs harmful substances, and finally is stored in the gas storage tank 7 after being compressed and boosted by the compressor 6, and the gas in the gas storage tank 7 can be used for generator power generation. Wherein the gas storage tank 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com