A kind of microwave wood tar cracking method and its device

A cracking device and wood tar technology, applied in the field of microwave wood tar cracking and its devices, can solve problems such as economic loss, equipment operation obstacles, production process interruption, etc., and achieve the effects of high quality and simple cracking process structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

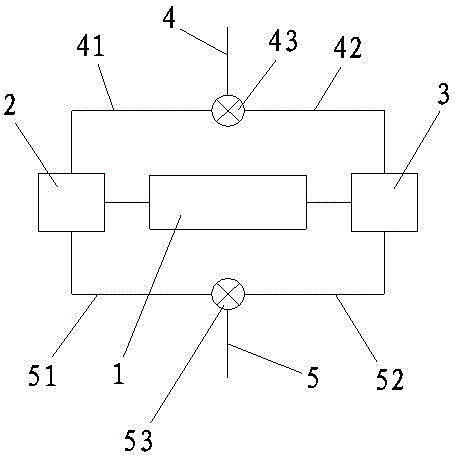

[0021] Embodiment one: if figure 1 As shown, a microwave wood tar cracking device includes a microwave oven 1, honeycomb activated carbon is arranged inside the microwave oven 1, a regenerator A (2) is arranged at the air inlet of the microwave oven 1, and the microwave oven 1 A regenerator B (3) is installed at the gas outlet, and the inlet of the regenerator A (2) is connected with a first air intake branch pipe 41 and a first gas outlet branch pipe 51, and the regenerator B (3) The entrance is connected with a second air intake branch pipe 42 and a second air outlet branch pipe 52, and the first air intake branch pipe 41 and the second air intake branch pipe 42 are all connected with an air intake main pipe 4, and the connection is provided with first three Through the switch valve 43, the first outlet branch pipe 51 and the second outlet branch pipe 52 are connected to an outlet main pipe 5, and a second three-way switch valve 53 is provided at the connection.

[0022] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com