Biochar processing system

A processing system and biochar technology, applied in the fields of biofuels, petroleum industry, special forms of dry distillation, etc., can solve the problems of environmental pollution, low utilization rate of resources, inability to separate tar and wood gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

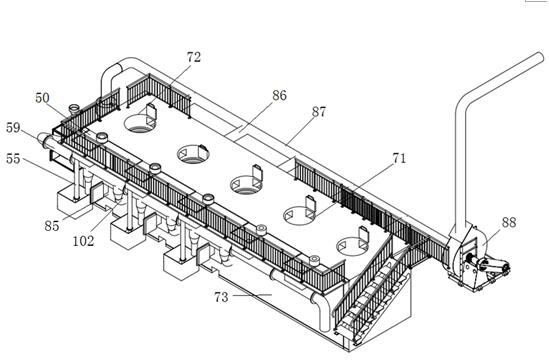

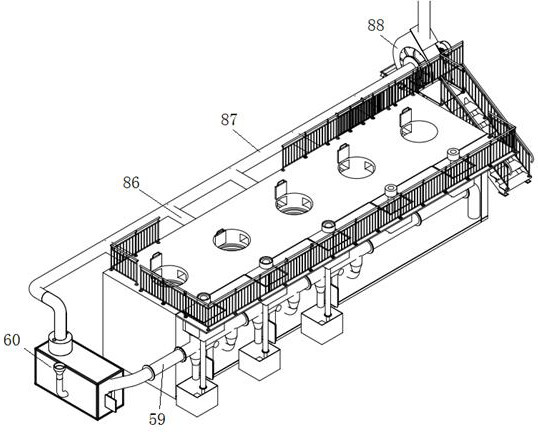

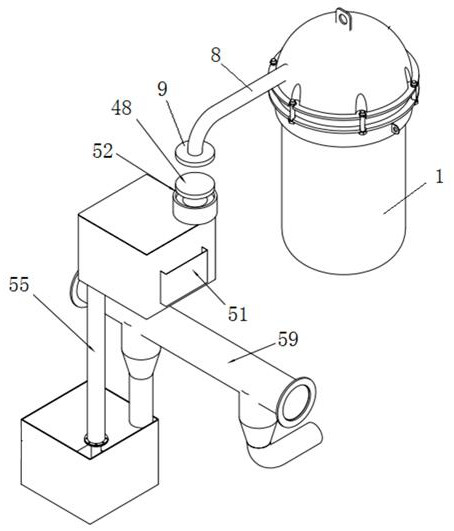

[0051] For the biochar processing system of this embodiment, please refer to Figure 1-Figure 16 , including a combustion base 73 with multiple preheating chambers 71 and multiple combustion chambers 72, the multiple preheating chambers 71 and multiple combustion chambers 72 communicate with each other, and multiple flue gas channels 81 are opened on the combustion base 73. The flue gas channel 81 connects multiple preheating chambers 71 and multiple combustion chambers 72 with each other. The combustion base 73 is provided with a wood gas delivery pipe 59, and the wood gas delivery pipeline 59 is connected with a plurality of branch pipes extending into the combustion chamber 72. 102, one end of the wood gas delivery pipe 59 is connected with the wood gas combustion furnace, the exhaust chimney 61, the preheating chamber 71, and the combustion chamber 72 of the wood gas combustion furnace are all connected with the flue gas induced draft fan, and the discharge pipe 8 of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com