Biochar production equipment

A technology for production equipment and biochar, which is applied in the direction of biofuel, combustion equipment, lighting and heating equipment, etc., and can solve the problems that wood gas cannot be recycled, increased labor intensity of workers, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

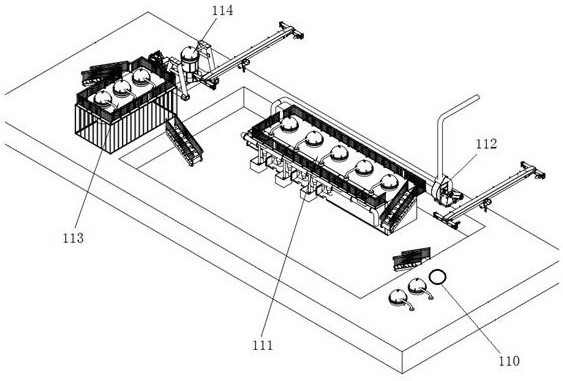

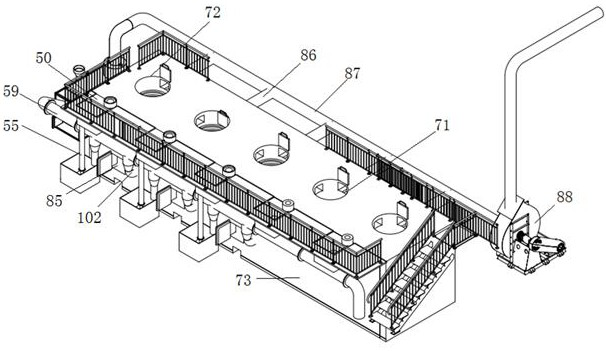

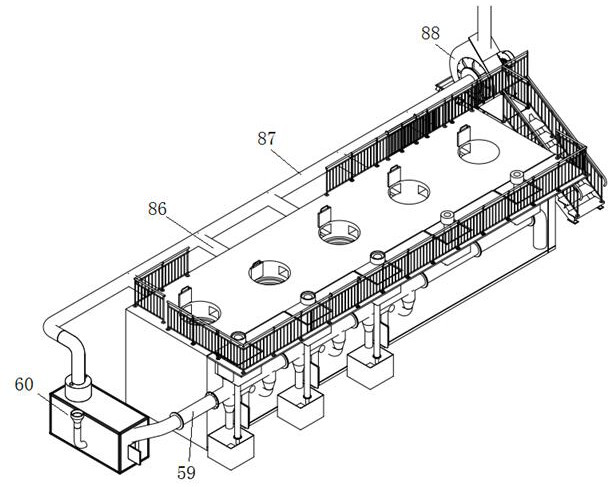

[0089] For the biochar production equipment of this embodiment, please refer to Figure 1-Figure 25 , including a plurality of reaction kettle placement areas 110 opened under the ground foundation, a combustion mechanism 111 for heating the reaction kettle, an air induction mechanism 112 for exhausting the exhaust gas from the combustion system to an external dust removal device, and an air induction mechanism 112 for completing the reaction. The reactor after the reactor carries out the cooling mechanism 113 of the reactor for cooling treatment, and the charcoal outlet mechanism 114 for taking out the biochar in the reactor;

[0090] The top of the reactor placement area 110 is open and flush with the ground, the reactor placement area is cylindrical, and the inner diameter of the reactor placement area is larger than the outer diameter of the reactor.

[0091] The specific structure of the reaction kettle: the reaction kettle includes a kettle body 1 and a kettle cover 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com