Wood gas permeability analysis and testing method

A technique for gas permeability, analytical testing, applied in permeability/surface area analysis, suspension and porous material analysis, analytical materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

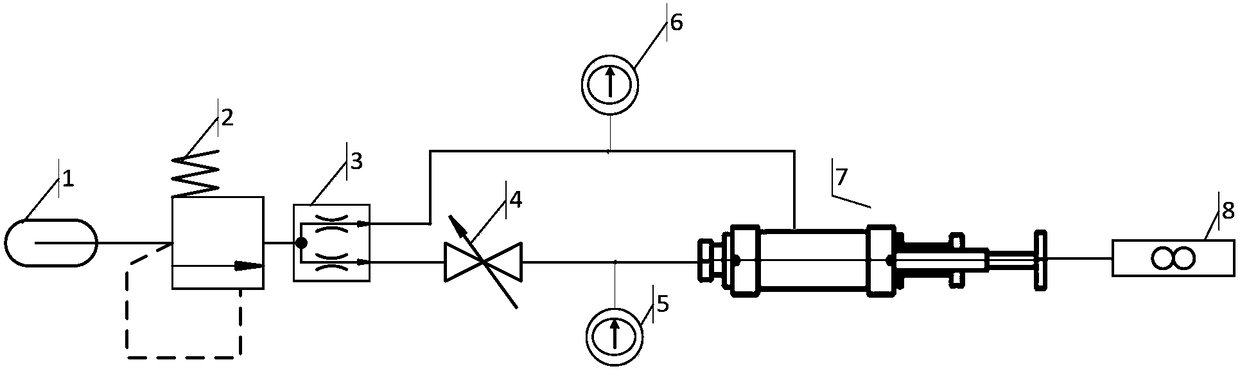

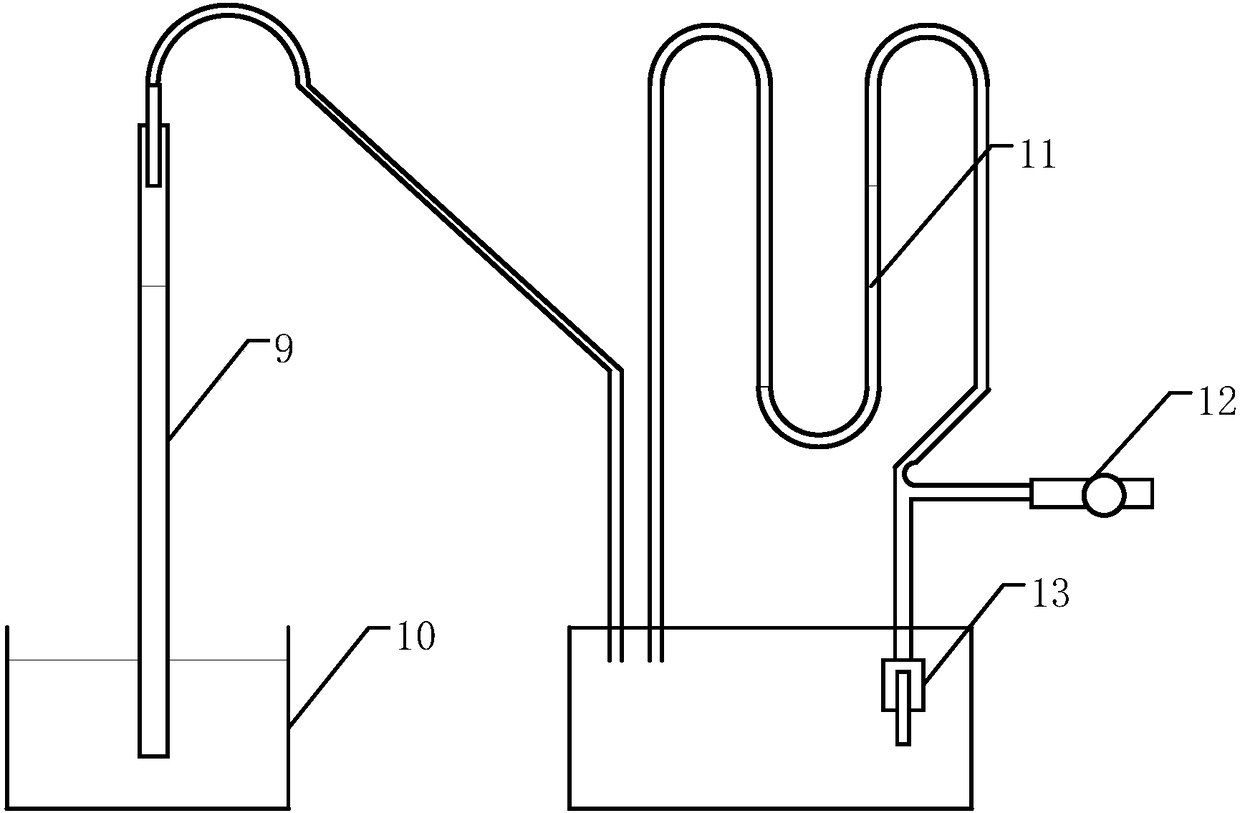

Method used

Image

Examples

Embodiment 1

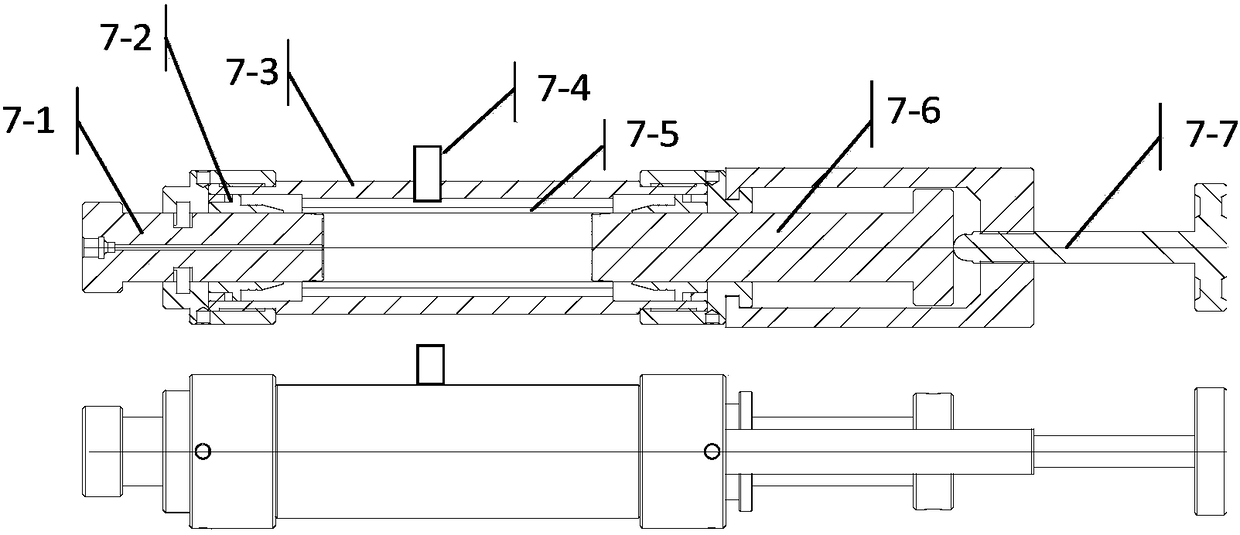

[0053] Longitudinal gas permeability measurement of conventional kiln-dried sawn timber of radiata pine: Use a coring drill to drill a 25mm-diameter wood longitudinal cylinder sample, use a vernier caliper to measure the appearance size of the wood sample before the test, the sample length L is 42.00mm, and the sample diameter 25.00mm, so the cross-sectional area A of the sample is 491mm 2 ;

[0054] Remove the low-pressure end plug of the wood sample holder, take out the fixed sample rubber sleeve in the sample chamber, place the wood sample to be tested in it, and then put the rubber cylinder containing the wood sample into the sample chamber. The ends are respectively connected to the high-pressure end plug and the low-pressure end plug, and the adjusting screw is turned to make the high-pressure end plug, the wood sample to be tested, and the low-pressure end plug contact;

[0055] Turn on the gas source switch (gas supplied by a nitrogen cylinder), supply gas to the wood...

Embodiment 2

[0060] Measurement of gas permeability in the chord direction of conventional kiln-dried sawn timber of radiata pine: use a coring drill to drill a wood longitudinal cylinder sample with a diameter of 25 mm, and use a vernier caliper to measure the appearance size of the wood sample before the test. The diameter is 25.00mm, so the cross-sectional area A of the sample is 491mm 2 ;

[0061] Remove the low-pressure end plug of the wood sample holder, take out the fixed sample rubber sleeve in the sample room, place the wood sample to be tested in it, and then put the rubber tube containing the wood sample into the sample room. The ends are respectively connected to the high-pressure end plug and the low-pressure end plug, and the adjusting screw is turned to make the high-pressure end plug, the wood sample to be tested, and the low-pressure end plug contact;

[0062] Turn on the gas source switch (gas supplied by a nitrogen cylinder), supply gas to the wood permeability tester, ...

Embodiment 3

[0067] Longitudinal gas permeability measurement of conventional kiln-dried sawn timber of Chinese fir: Use a coring drill to drill a 25mm diameter wood longitudinal cylinder sample, use a vernier caliper to measure the appearance size of the wood sample before the test, the sample length L is 20.70mm, and the sample diameter is 24.70 mm, so the sample cross-sectional area A is 479mm 2 ;

[0068] Remove the low-pressure end plug of the wood sample holder, take out the fixed sample rubber sleeve in the sample room, place the wood sample to be tested in it, and then put the rubber tube containing the wood sample into the sample room. The ends are respectively connected to the high-pressure end plug and the low-pressure end plug, and the adjusting screw is turned to make the high-pressure end plug, the wood sample to be tested, and the low-pressure end plug contact;

[0069] Turn on the gas source switch (gas supplied by a nitrogen cylinder), supply gas to the wood permeability ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com