Biomass type intelligently-integrated essence charcoal gasoline extraction technology and system thereof

A biomass and essence technology, applied in the field of biomass refining process and system, can solve the problems of a large amount of waste gas and dust, unsatisfactory environmental protection, and low production profit, so as to improve environmental protection, increase product added value, and increase production profit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

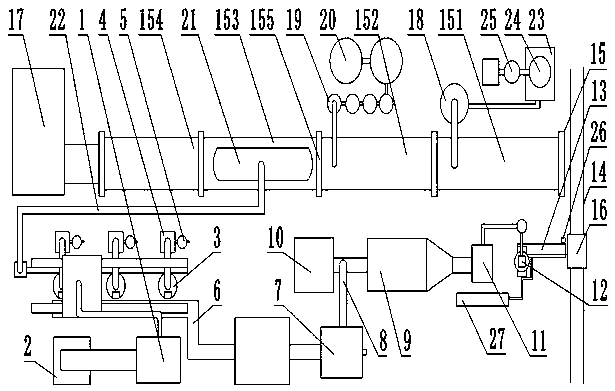

[0025] Example. Biomass intelligent integrated flavor charcoal gasoline refining process, such as figure 1 shown, including the following steps:

[0026] a, Biomass essence refining area, send the sawdust in the hopper 2 to the retort 3 to carry out pyrolysis with conveying fan 1, obtain the sawdust, steam and menthol after distillation;

[0027] b. Send steam and menthol into the cooler 4 in the cooling water tank through the oil-gas delivery pipe for cooling and liquefaction, and then use the oil-water separation box 5 to separate oil and water to obtain menthol;

[0028] c. In the drying rod making area, send the distilled sawdust to the roller sieve 7 to separate the coarse sawdust from the fine sawdust, and send the fine sawdust to the tumble dryer 9 through the stirring cage 8 for overturning and drying to generate wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com