Device for producing wood charcoal and recovering wood vinegar and wood tar

A technology for wood tar and wood vinegar, which is applied to the device of wood tar, produces charcoal and recovers wood vinegar, can solve the problems of unstable product quality, long production cycle, large fuel consumption, etc., and achieves simple structure and good recovery. The effect of utilizing and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

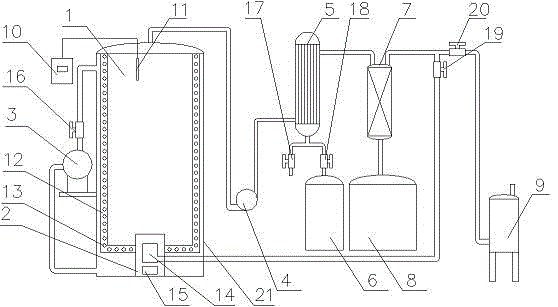

[0014] see figure 1 , a device for producing charcoal and recovering wood vinegar and wood tar, which is composed of a carbonization furnace 21, an induced draft fan 4, a condenser 5, a low-temperature condenser 7 and a flue gas filter 9, the carbonization furnace 21, an induced draft fan 4. The condenser 5, the low-temperature condenser 7 and the flue gas filter 9 are sequentially connected through pipelines, and a branch is provided on the pipeline 9 between the low-temperature condenser 7 and the flue gas filter to connect with the carbonization furnace 21. Described carbonization furnace 21 is made up of carbonization chamber 1 and combustion chamber 2, and described carbonization chamber 1 is provided with temperature probe 11, and described carbonization chamber 1 is provided with temperature indicator 10, and described temperature indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com