A preparation method and application of wood airgel for oxygen and hydrogen production by alkaline seawater electrolysis

An aerogel and wood technology, which is applied in electrolysis components, electrolysis process, electrodes, etc., can solve the problems of insufficient activity of full electrolysis bifunctional catalysts, catalyst poisoning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0036] Specific Embodiment 1: In this embodiment, a method for preparing wood airgel for alkaline seawater electrolysis to produce oxygen and hydrogen is completed according to the following steps:

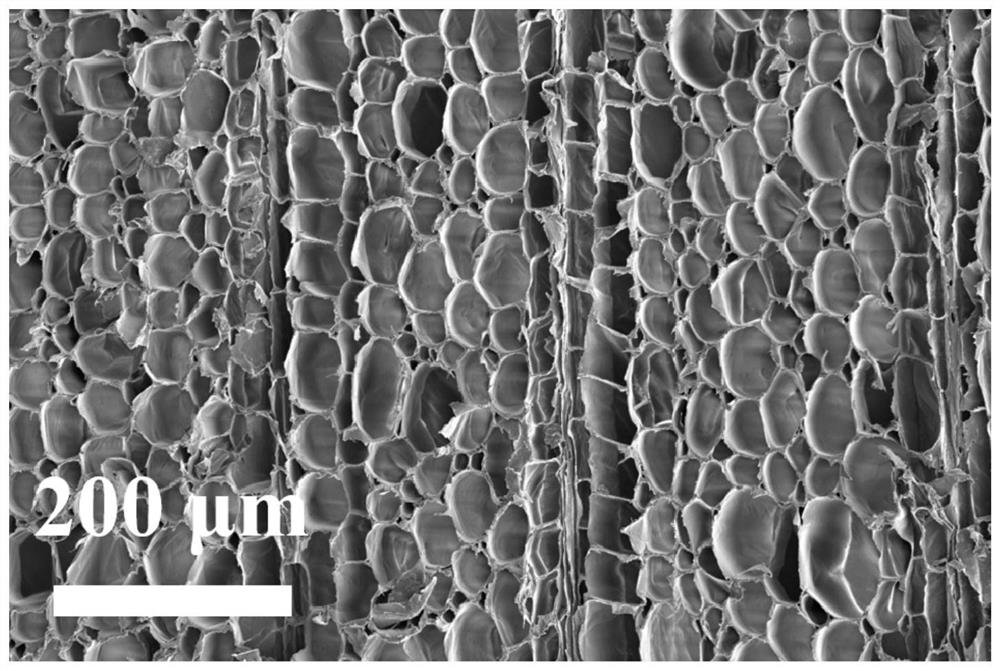

[0037] 1. First remove lignin and hemicellulose from natural porous wood, then wash, and finally freeze-dry to obtain wood airgel from which lignin and hemicellulose have been removed;

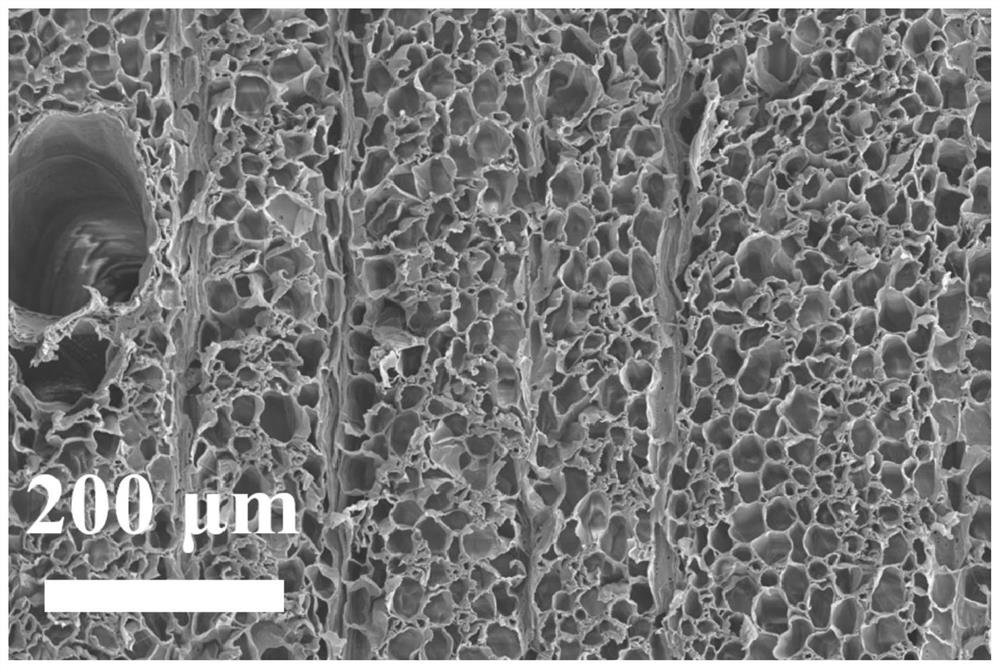

[0038] 2. Immerse the wood airgel with lignin and hemicellulose removed in NaBH 4 / NaOH mixed solution for activation to obtain activated wood airgel;

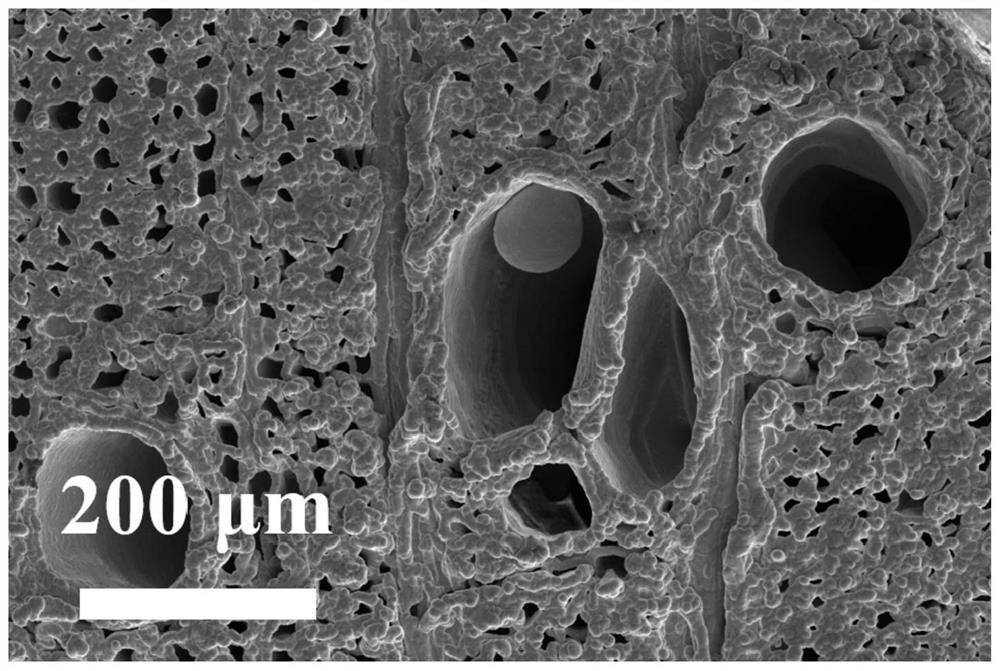

[0039] 3. Immerse the activated wood airgel in the plating solution for plating, take it out and dry it in vacuum to obtain the wood airgel loaded with nickel-molybdenum-phosphorus alloy;

[0040] The plating solution described in the step 3 is made of NiSO 4 ·6H 2 O, Na 2 MoO 4 .2H 2 O, NaH 2 PO 2 ·H 2 O, CH 3 COONa, C 6 h 5 Na 3 o 7 2H 2 O, NH 3 ·H 2 O mixed with water;

[0041] 4. Putting the wood airgel loaded with nickel-mol...

specific Embodiment approach 2

[0047] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the method for removing lignin and hemicellulose of natural porous wood in step 1 is: first, immerse the natural porous wood in a temperature of 90°C to 100°C. NaOH and Na 2 SO 3 8h~10h in the mixed solution, then immersed in the NaOH solution at a temperature of 70°C~80°C for 6h~8h, and finally immersed in 40°C~60°C H 2 o 2 1h~3h in the solution. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0048] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: NaOH and NaOH described in step one 2 SO 3 The concentration of NaOH in the mixed solution is 80g / L~100g / L, NaOH 2 SO 3 The concentration of the NaOH solution is 40g / L~50g / L; the mass fraction of the NaOH solution is 5%~8%; the H 2 o 2 The concentration of the solution is 65g / L-85g / L. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com