Internal circulation biomass carbonization device

A biomass charcoal and chemical device technology, which is applied in the fields of biofuels, direct heating dry distillation, special forms of dry distillation, etc., can solve the problems of low heat exchange efficiency and bulky heating equipment, so as to improve heat exchange efficiency and accurately control the carbonization temperature. , the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

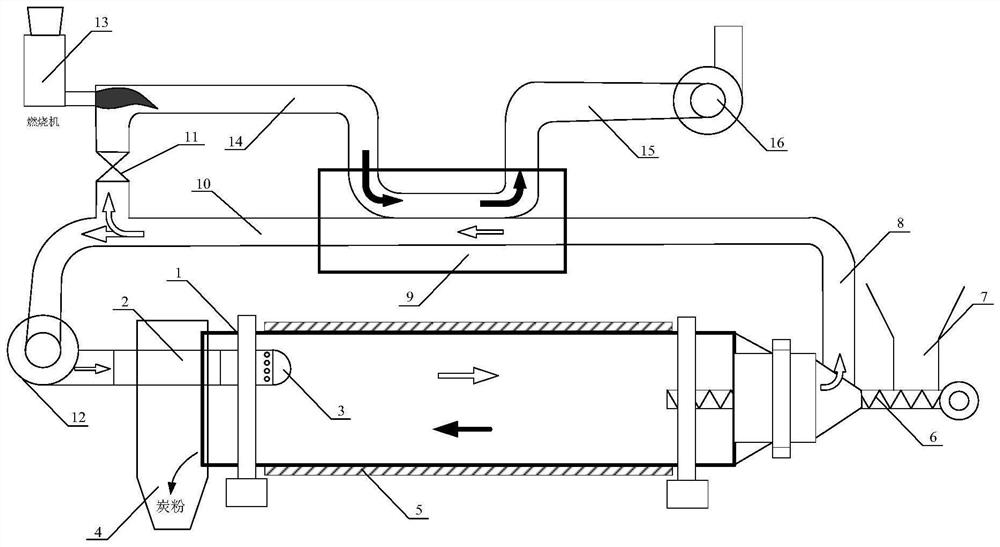

[0031] The technology and beneficial effects of the internal circulation biomass carbonization device provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments. The dimensions of each component are not limited to those listed in the following examples, and can be manufactured according to actual needs, and commercially available conventional products can also be used for components not specified in detail.

[0032] see figure 1 , an internal circulation biomass carbonization device, including a rotary kiln 1, a rotary kiln intake pipe 2, a wind cap 3, a blanking port 4, an insulating material 5, a feeder 6, a feed hopper 7, a low-temperature wood gas pipe 8, Gas heat exchanger 9, high-temperature wood gas pipeline 10, gas valve 11, high-temperature fan 12, burner 13, high-temperature flue 14, low-temperature flue 15, tail gas fan 16; The gas pipeline 2 is connected to the air outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com