Super-capacitance carbon prepared by utilizing apple trimmed scrap branches, as well as preparation method and application thereof

A technology for supercapacitors and capacitive carbons, applied in applications, hybrid capacitor electrodes, chemical instruments and methods, etc., can solve the problems of unstable raw material sources, complex preparation processes, and poor electrochemical performance of supercapacitor activated carbons, and achieve excellent electrochemical performance. performance, reduce environmental pollution, and reduce transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

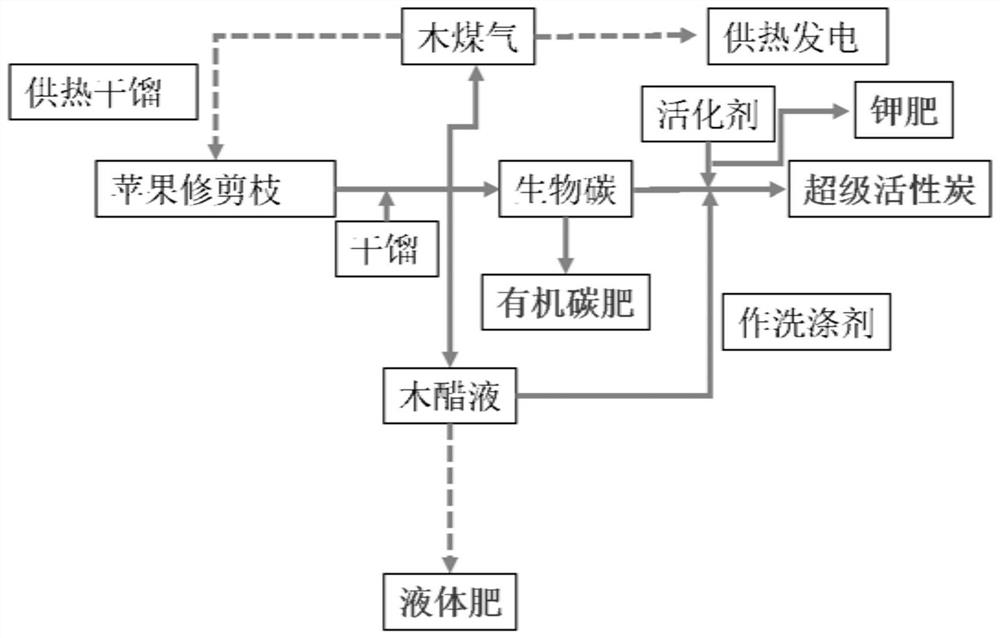

[0039] see figure 1 , the preparation method of the supercapacitor carbon provided by the present embodiment comprises the following steps:

[0040] 1) Apple pruning branches are crushed to 5 cm long small sections of waste branches;

[0041] 2) A small section of waste branches is added to the retort, and the condensing device and the tail gas purification and absorption device are turned on at the same time; the retort is heated to 500°C at a heating rate of 5°C / min, and kept at this temperature for 2 hours, and the condensed gas is collected during the process. Liquid and tail gas to obtain pre-carbonized products, dry distillation liquid and wood gas;

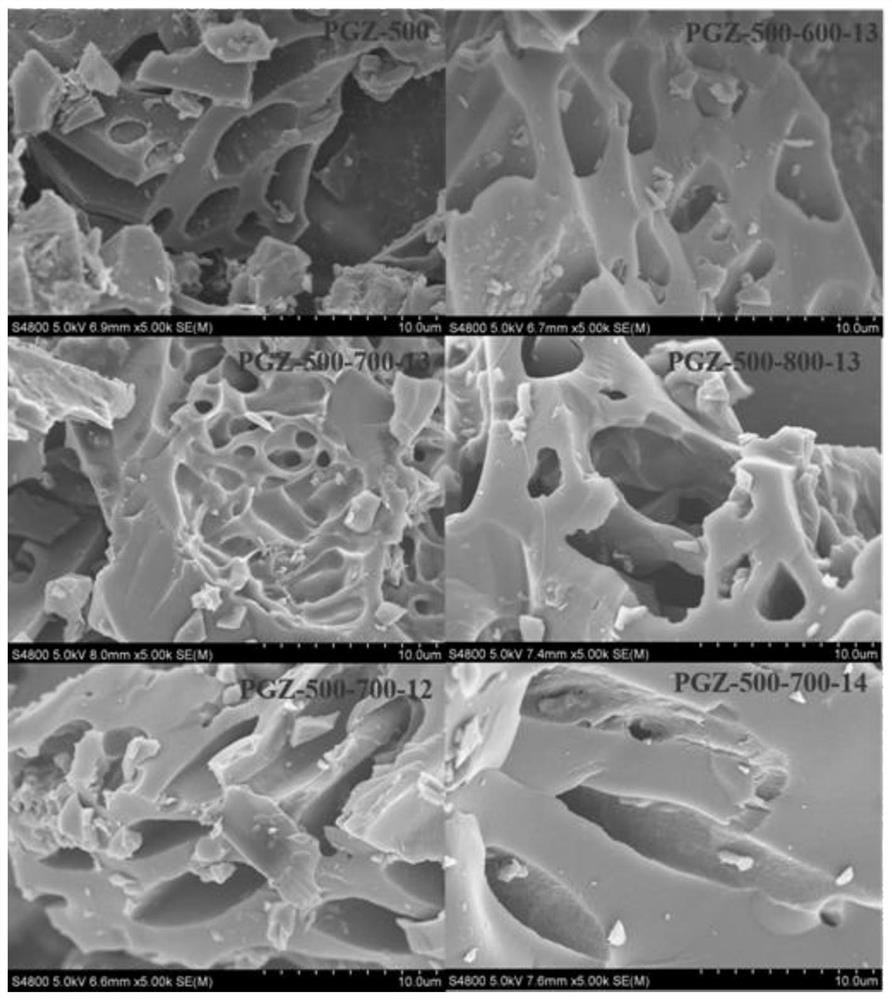

[0042] 3) After dry distillation, cool down at room temperature naturally, fully mix and grind the pre-carbonized product and activator (potassium hydroxide) at a mass ratio of 1:3 (carbon:alkali), and transfer the mixture to an activation furnace. Raise the temperature to 600°C at a heating rate of 5°C / min, and keep at t...

Embodiment 2

[0047] see figure 1 , the preparation method of the supercapacitor carbon provided by the present embodiment comprises the following steps:

[0048]1) Apple pruning branches are crushed to 3 cm long small sections of waste branches;

[0049] 2) A small section of waste branches is added to the retort, and the condensing device and the tail gas purification and absorption device are turned on at the same time. The retort is heated up to 500°C at a heating rate of 5°C / min, and kept at this temperature for 2 hours. During the process, the condensed liquid and tail gas are collected to obtain pre-carbonized products, dry distillation liquid and wood gas;

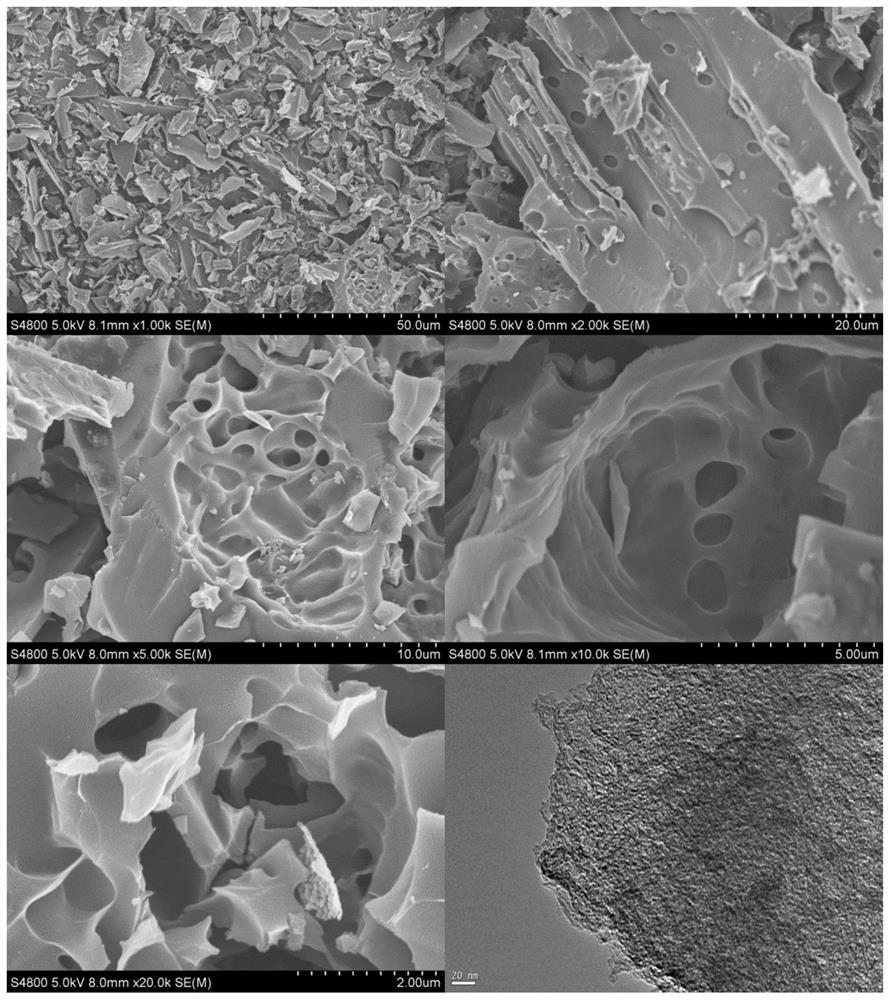

[0050] 3) After dry distillation, cool down at room temperature naturally, fully mix and grind the pre-carbonized product and activator (potassium hydroxide) at a mass ratio of 1:3 (carbon:alkali), and transfer the mixture to an activation furnace. Raise the temperature to 700°C at a heating rate of 5°C / min, and keep at this t...

Embodiment 3

[0055] see figure 1 , the preparation method of the supercapacitor carbon provided by the present embodiment comprises the following steps:

[0056] 1) Apple pruning branches are crushed to 4 cm long small sections of waste branches;

[0057] 2) A small section of waste branches is added to the retort, and the condensing device and the tail gas purification and absorption device are turned on at the same time. The retort is heated up to 500°C at a heating rate of 5°C / min, and kept at this temperature for 2 hours. During the process, the condensed liquid and tail gas are collected to obtain pre-carbonized products, dry distillation liquid and wood gas;

[0058] 3) After dry distillation, cool down at room temperature naturally, fully mix and grind the pre-carbonized product and activator (potassium hydroxide) at a mass ratio of 1:3 (carbon:alkali), and transfer the mixture to an activation furnace. Raise the temperature to 800°C at a heating rate of 5°C / min, and keep at this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com