Method for carrying out equipment extraction on charcoal, wood gas, wood tar and wood vinegar

A technology of wood tar and wood vinegar, which can be used in wood gas, charcoal, wood vinegar for equipment extraction, and wood tar field, can solve the problem of air pollution and fire safety hazards, affect traffic and people's health, and affect the village. to promote a virtuous cycle and utilization of biomass energy, prevent soil desertification and soil erosion, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

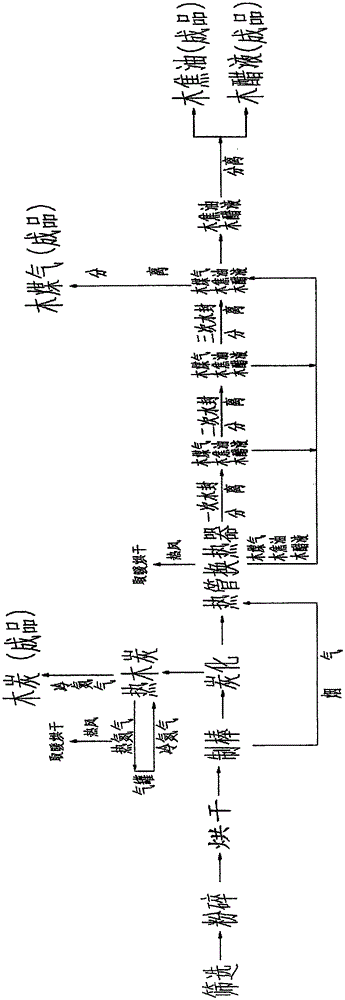

[0023] see figure 1 A method for equipment extraction of charcoal, wood gas, wood tar, and wood vinegar, comprising the following steps:

[0024] (1) Screening: according to the different types of raw materials, the raw materials are stored separately;

[0025] (2) Pulverization: put the raw material with irregular shape and size in the step (1) into a pulverizer, and pulverize it into wood chips with uniform fineness of about 3mm;

[0026] (3) Drying: use a dryer to dry the sawdust in step (2) until the moisture content reaches 8%-12%;

[0027] (4) Rod making: the raw material after pulverizing and drying is utilized a rod making machine to be made into a hollow strip semi-finished fuel rod; the diameter of the semi-finished fuel rod in the step (4) is 50mm, and the length is 360mm-400mm;

[0028] (5) Carbonization: put the semi-finished fuel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com