Wood-gas combinative integrated stove

A technology that integrates stoves and firewood gas, applied in household stoves, household stoves/stoves, gaseous heating fuel, etc., can solve the problems of wasting kitchen space, poor installation of exhaust gas outlets, and inconvenient house design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

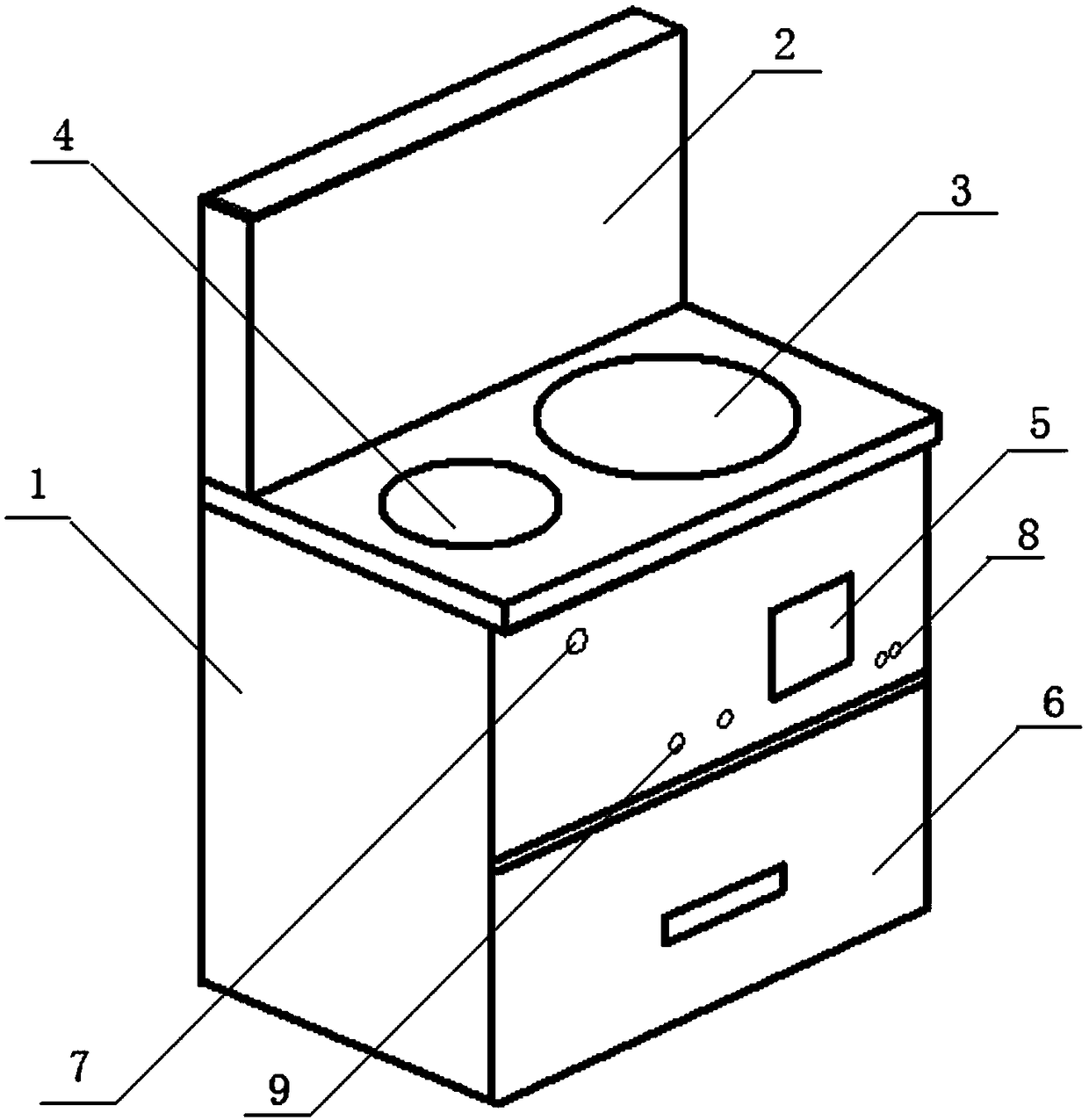

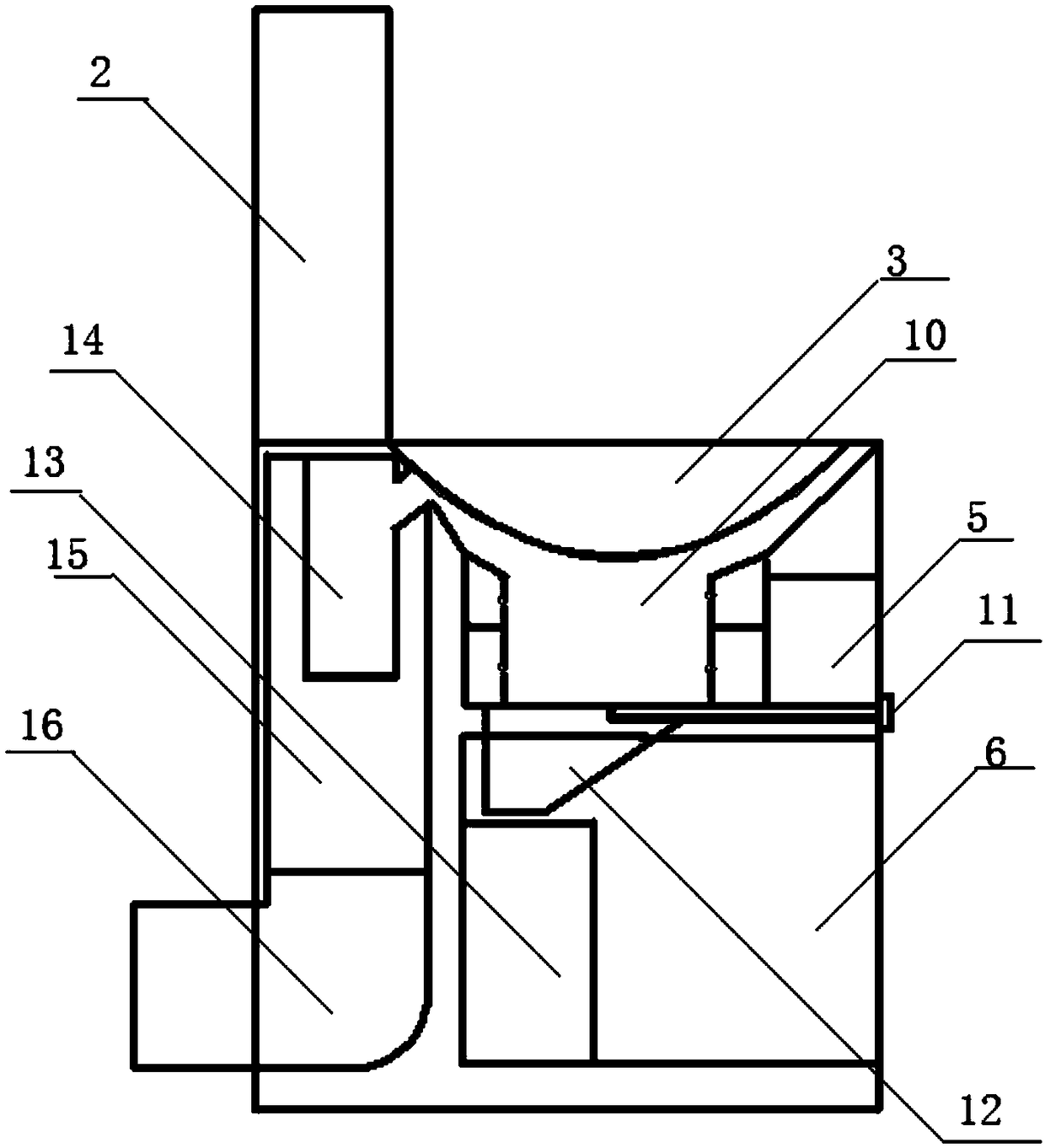

[0017] Embodiment 1: An integrated firewood and gas stove according to the present invention. There are two stoves, a firewood stove 3 and a gas stove 4, on the table of the stove body 1. The opening and closing of the furnace 4 and the size of the firepower, the firewood stove 3 is provided with a combustion chamber 10, and the combustion materials required for the firewood stove 3 are input from the feed port 5 on the side of the combustion chamber 10, and the top of one side of the combustion chamber 10 is connected with a combustion chamber Exhaust gas inner pipe 14, oil fume and exhaust gas outer pipe 15. Negative pressure is generated at the exhaust gas discharge inner pipe 14 when the oily fume exhaust gas is discharged, so that the exhaust gas during combustion is automatically sucked out to discharge the exhaust gas. There is an ash leakage funnel 12 under the combustion chamber 10 furnace bridge. A pull-rod-shaped ash leak switch 11 is arranged between the furnace bri...

Embodiment 2

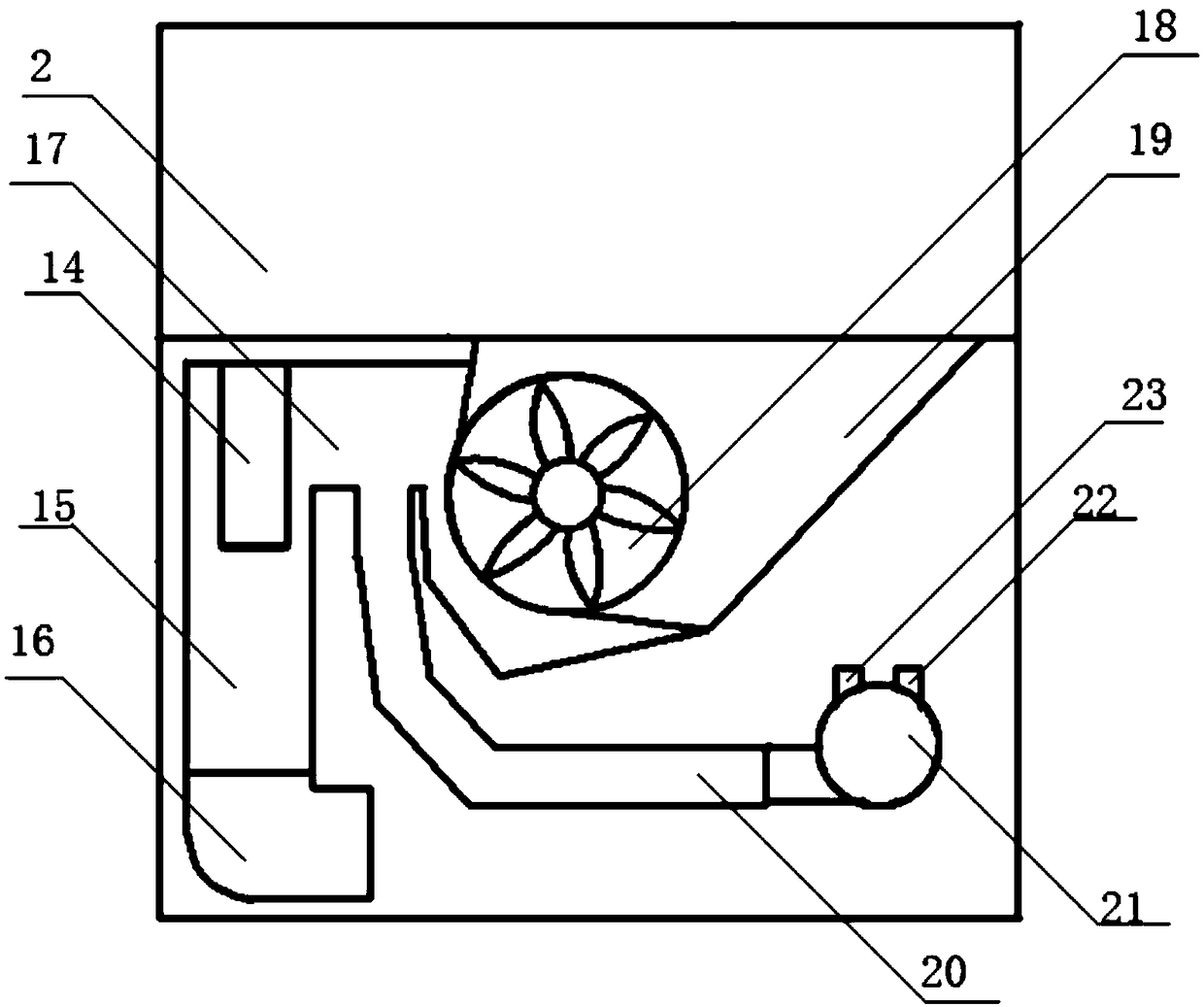

[0018] Embodiment 2: An integrated firewood and gas stove according to the present invention. Two stoves, a firewood stove 3 and a gas stove 4, are arranged on the table of the stove body 1. The gas stove 4 controls the gas through the gas stove switch 7 set in front of the stove body 1. The opening and closing of the furnace 4 and the size of the firepower, the firewood stove 3 is provided with a combustion chamber 10, and the combustion materials required for the firewood stove 3 are input from the feed port 5 on the side of the combustion chamber 10, and the top of one side of the combustion chamber 10 is connected with a combustion chamber Exhaust gas inner pipe 14, oil fume and exhaust gas outer pipe 15. Negative pressure is generated at the exhaust gas discharge inner pipe 14 when the oily fume exhaust gas is discharged, so that the exhaust gas during combustion is automatically sucked out to discharge the exhaust gas. There is an ash leakage funnel 12 under the combustion...

Embodiment 3

[0019] Embodiment 3: an integrated firewood and gas stove according to the present invention is characterized in that two firewood stoves 3 and a gas stove 4 are arranged on the table of the stove body 1, and the gas stove 4 is controlled by the switch 7 provided in front of the stove body 1 Opening and closing and size, there is a combustion chamber 10 under the firewood stove 3, and the raw materials required for using the firewood stove 3 are input from the feed port 5 on the side of the combustion chamber 10, and the top of one side of the combustion chamber 10 is connected with a combustion chamber exhaust gas inner pipe 14. Oily fume and exhaust gas outer pipe 15. When the oily fume exhaust gas is discharged, a negative pressure is generated at the exhaust gas discharge inner pipe 14, so that the exhaust gas during combustion is automatically sucked out to discharge the exhaust gas. There is an ash funnel 12 under the furnace bridge of the combustion chamber 10, and the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com