Cleaner production system of carbonization furnace group

A clean production and carbonization furnace technology, which is applied in carbonization furnaces, coke ovens, biofuels, etc., can solve the problems of intermittent carbonization furnaces that cannot transfer mass and heat between furnaces, and achieve increased output value and profit, efficient production, and improved thermal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

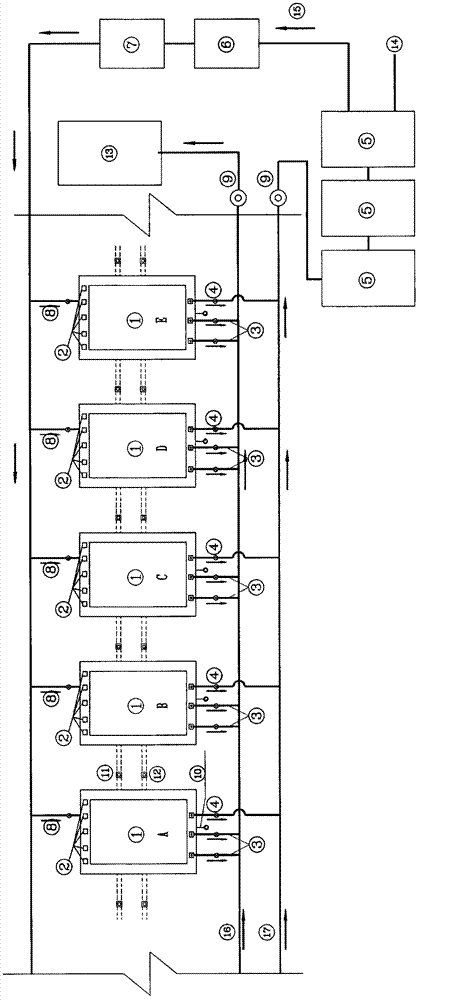

[0028] The pyrolysis furnace designed by this patent belongs to the intermittent production pyrolysis furnace, but works in the mode of furnace group, and its main production process is as follows ( figure 1 ):

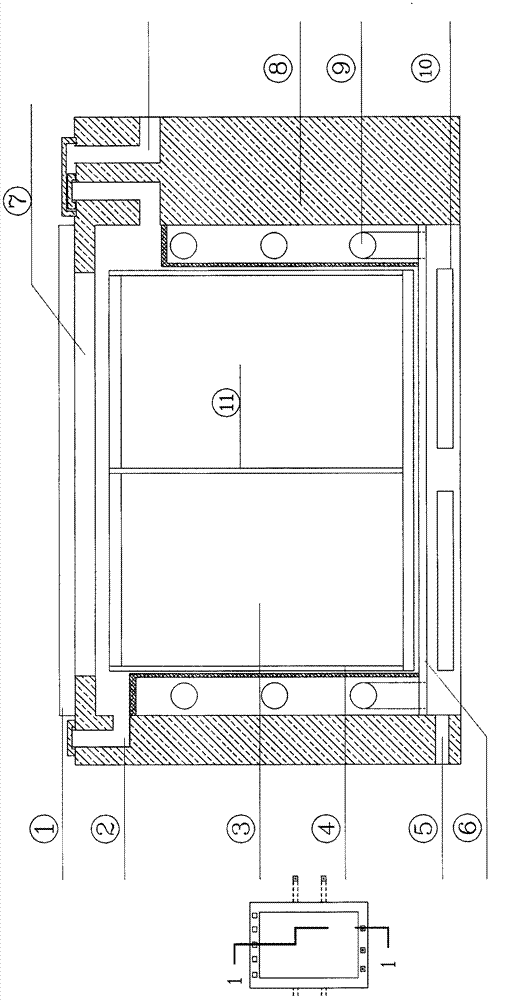

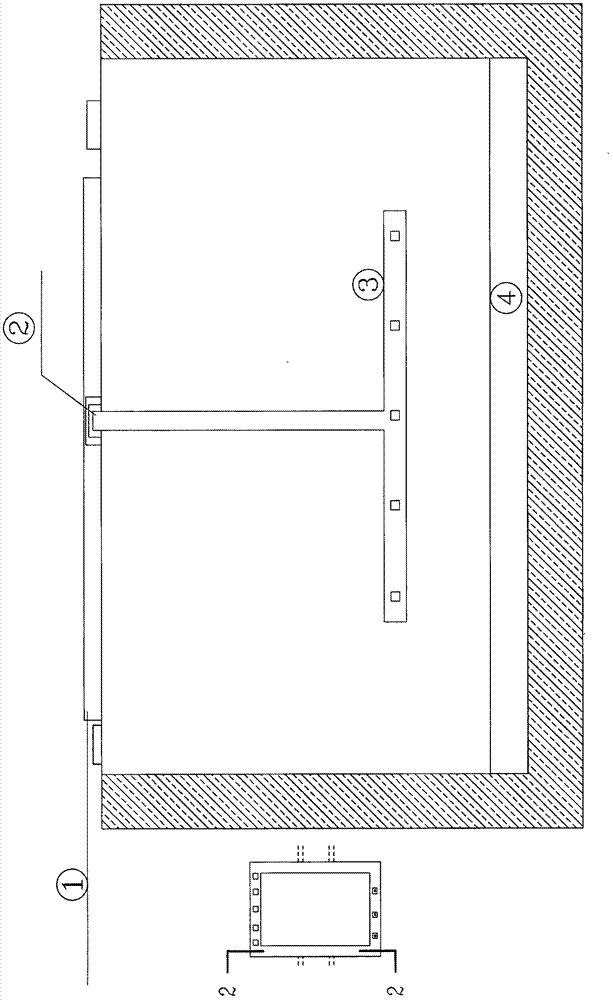

[0029] In the carbonization chamber (ABCD) ① the carbonization cage ( figure 2 ) is filled with biomass, and the air inlet of A carbonization chamber ② ( Figure 5 ) to open (it must be closed when no spontaneous combustion heating is required), and the mass transfer between furnaces heat transfer aisle( image 3 , Figure 4 , Figure 6 , Figure 7 ) connected, close the flue gas and oil gas outlets of the furnace and carbonization chamber ③( Figure 5 ), start the exhaust fan ⑨, ignite the biomass in the carbonization cage or ignite the furnace combustion device, and cover the cover plate of the ABCD carbonization chamber ① ( Figure 8 , Figure 9 ). At the same time, the carbonization furnace in the next 3 (BCD) process closes the air inlet ②, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com