Multifunctional fire gathering cover and infrared energy gathering and flame dividing net cover for clean type firewood-gas stove

A fire-gathering hood and infrared technology, applied in the field of diesel gas furnaces, can solve the problems of slow temperature rise, unfavorable gasification reaction, and insufficient combustion of wood-fired furnaces, so as to prolong the residence time, increase the heat extraction area, and improve the thermal efficiency. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

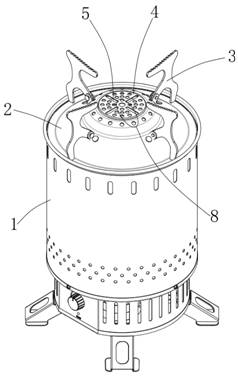

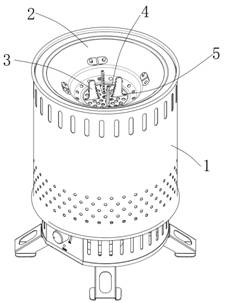

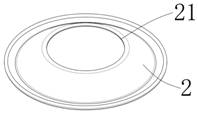

[0034] Example 1 please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 In one embodiment shown, a multi-functional flame gathering cover for a clean type diesel gas stove and an infrared ray energy-gathering flame-distributing net cover include a diesel gas furnace body 1, and a fire gathering flame is installed on the furnace fire outlet of the diesel gas furnace body 1. Cover 2, the upper surface of the fire gathering cover 2 is hinged with a plurality of overturned pot supports 3 uniformly distributed along the circumferential direction, and the infrared ray gathering energy distribution flame net cover 4 is installed on the fire gathering cover 2, and the infrared ray gathering energy dividing The flame net cover 4 is provided with a bar hole 5 for accommodating the inverted pot support 3; wherein,

[0035] The fire-gathering cover 2 and the infrared-ray energy-gathering flame-distributing screen cover 4 are metal thin-walled conical ci...

Embodiment 2

[0044] On the basis of the above-mentioned embodiment 1, please refer to the embodiment 2 Figure 7 , Figure 8 , Figure 9 and Figure 10 In one embodiment shown, the infrared ray energy-gathering flame-distributing screen cover 4 is provided with a single burner port 7 or a plurality of uniform flame-distributing holes 8, and the inner surface of the burner port 7 or the flame-distributing holes 8 is provided with The refractory material mesh 6 .

[0045] Preferably, the sub-flame hole 8 is set as the first mixing hole 41 of the rod hole plus the round hole, or the second mixing hole 42 of the bar hole 5 plus the round hole, or the third mixing hole of the annular auxiliary hole plus the main hole. Hole 43, or the fourth mixing hole 44 of circular waist hole plus round hole.

[0046] The infrared ray energy-gathering flame-distributing net cover 4 is provided with a single flame spout 7, and with the refractory material net 6, the effect of flame concentration and infrar...

Embodiment 3

[0050] On the basis of the above embodiments, embodiment 3 shows an embodiment, the refractory material mesh 6 is a nickel wire mesh, and the mesh number of the nickel wire mesh is 30 mesh to 80 mesh.

[0051] After the conical opening of the infrared energy-gathering flame-distributing net cover 4 is equipped with nickel wire mesh, the combustion effect can be further enhanced, and the high temperature state of the conical opening can be continuously maintained in the form of infrared heat radiation, thereby improving the heat utilization rate, while the nickel wire mesh The mesh number is 30 mesh-80 mesh to prevent most of the furnace ash from running out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com