Continuous carbonization furnace for waste wood chips

A technology of carbonization furnace and waste wood chips, which is used in coke ovens, coke ovens with mechanical devices, and biofuels, etc., can solve the problem of not providing purified wood gas, etc., and achieves high operational flexibility, low energy consumption, and improved utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

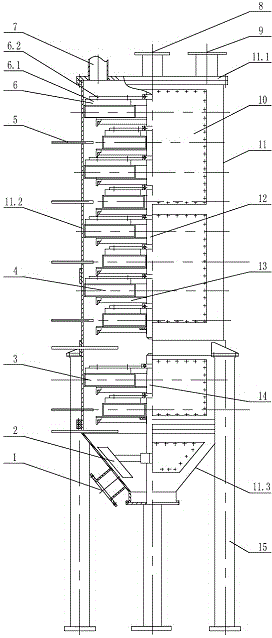

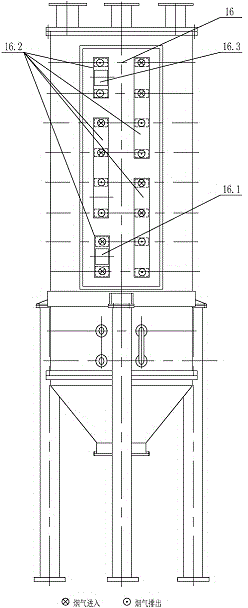

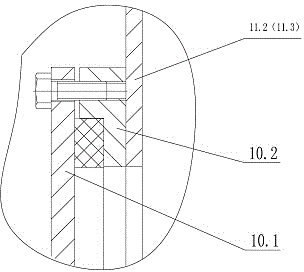

[0026] like figure 1 , figure 2 As shown, the present invention has a closed tower body 11, on the upper end cover 11.1 of the tower body 11, a reaction gas outlet pipe 7, a nitrogen gas inlet pipe 8 and a waste sawdust inlet pipe 9 are arranged, and the cylinder body 11.2 top of the tower body 11 is along the A plurality of angle steel brackets 13 are installed in the axial direction, and a large heating plate 4 and a small heating plate 4 are respectively fixed on each angle steel bracket. , each angle steel bracket is fixed with a large cooling plate 3 and a small cooling plate 3 alternately; the flow channels of multiple heating plates 4 are connected in series with the flue gas distribution system 16 outside the tower body 11, and the multiple heating plates 4 are The scraping and stirring device 6 is driven to rotate by the upper transmission shaft 12, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com