Biomass high-rise cold wood burner and its application method

A biomass and high-level technology, applied in the manufacture of combustible gas, petroleum industry, mechanical details of gasification devices, etc., can solve the problems of low conversion efficiency of wood gas and inconvenient cleaning and maintenance of slag, so as to improve conversion efficiency and combustion speed, realize Clean up work, cleverly structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

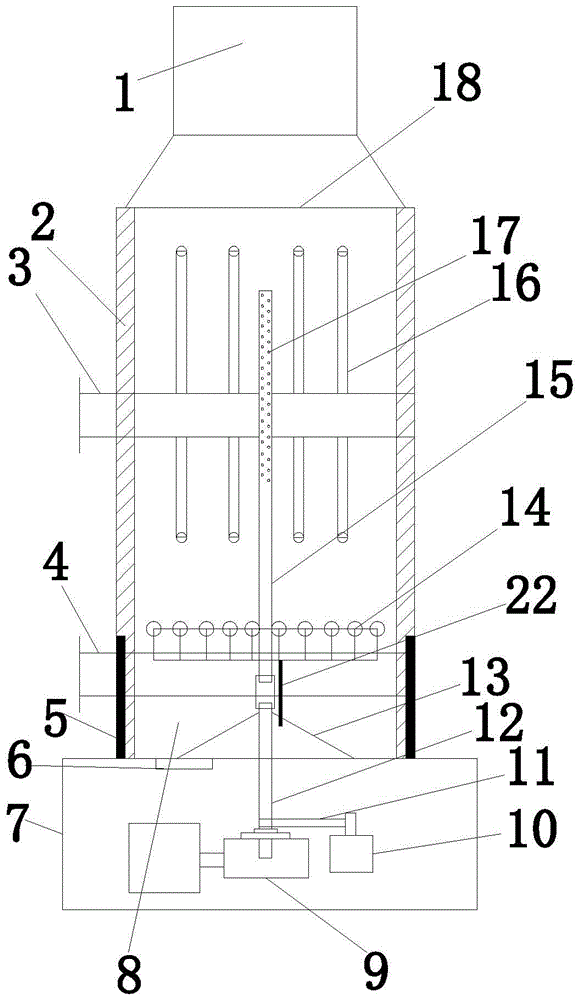

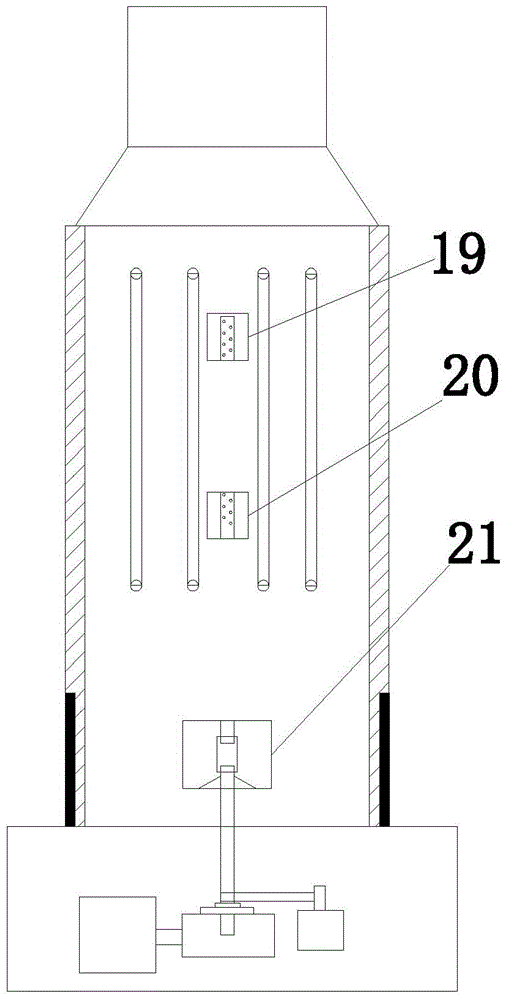

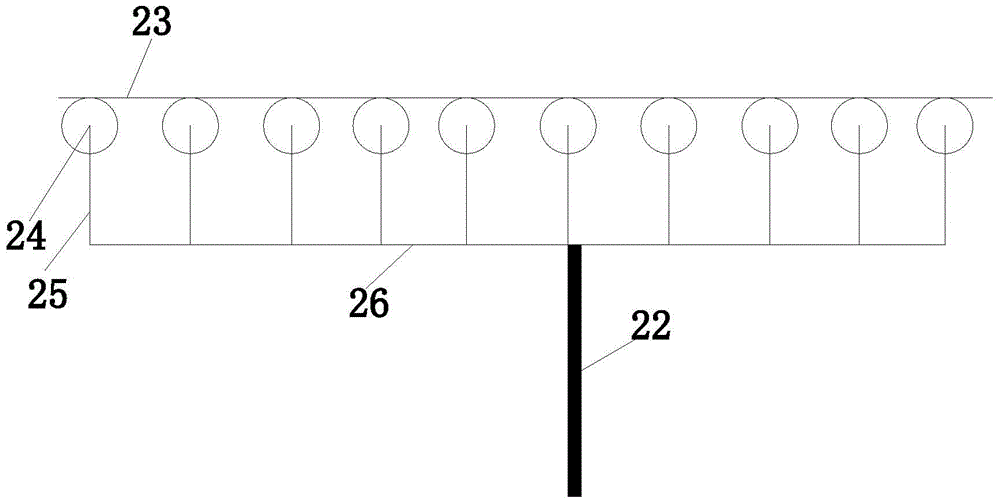

[0019] Example. Biomass high-rise cold wood burner, constituted as Figure 1-3 Shown, comprise the furnace body 18 that is arranged on the frame 7, the upper end of the furnace body 18 is provided with feed inlet 1, is provided with wood gas upper outlet 3 and wood gas lower outlet 4 on the side wall of furnace body 18, the bottom of furnace body 18 There is an ash chamber 8, on which there is a flap ash discharge pan 14, a carbon discharge port 6 is provided at the bottom of the ash chamber 8, an ash discharge mechanism is provided under the furnace body 18, and an ash discharge power mechanism is provided. Connected with a hollow rotating tube 12, the lower end of the rotating tube 12 is set in the air inlet box 9, the upper end is provided with a number of scrapers 13 and set in the ash chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com