Technique for producing concentrated clear peach juice

A production process and juice-clearing technology, applied in application, food preparation, food science and other directions, can solve the problems of fruit juice deterioration, affecting the appearance, flavor, and loss of nutrients, and achieve the goal of accelerating clarification, improving juice yield, and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

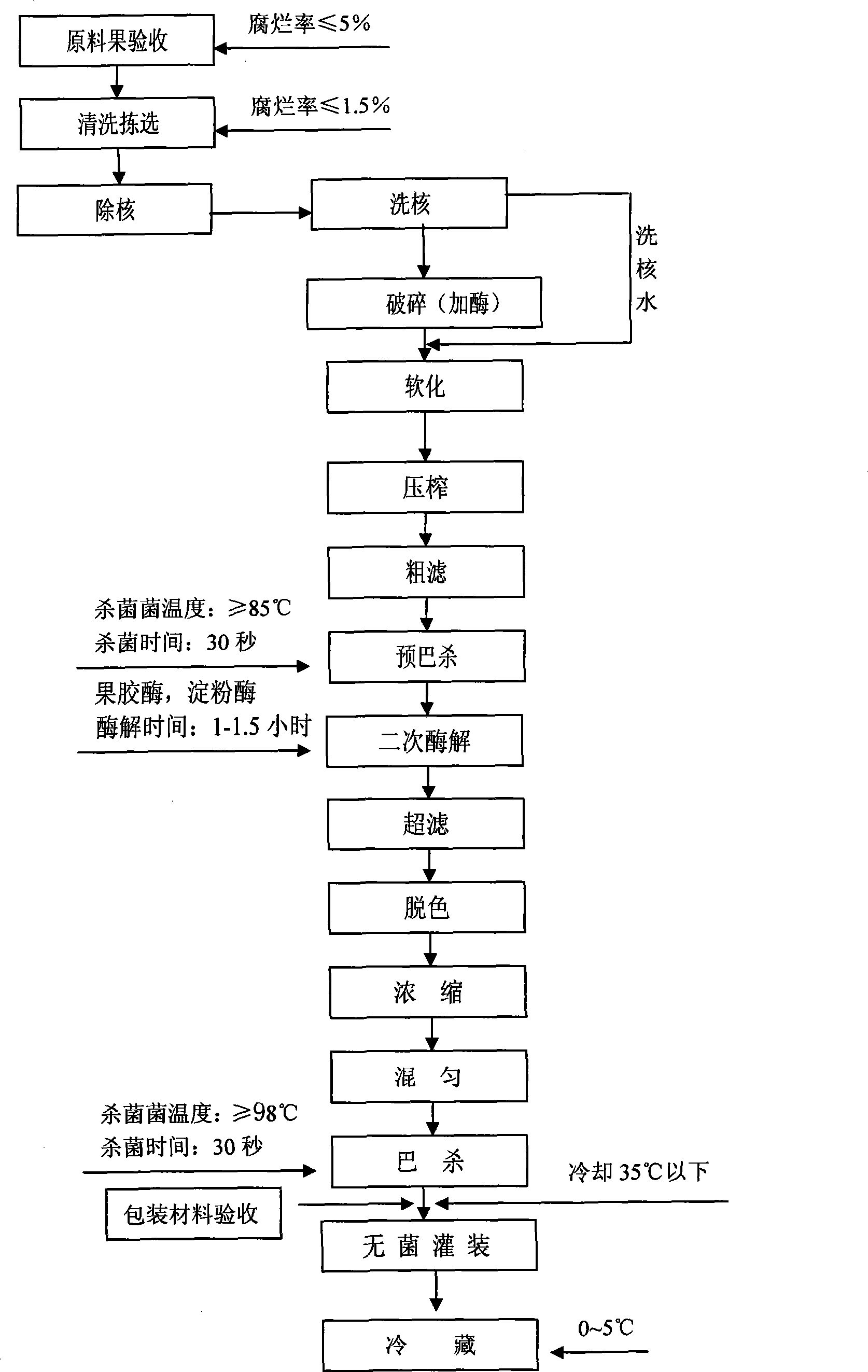

[0031] Embodiment 1 A kind of production technology of concentrated peach clear juice, see figure 1 , including the following steps:

[0032] (1) Cleaning and selecting raw peaches (juicy peaches) require no pests, no pollution, no rot, and a diameter of more than 60mm. The peaches are cleaned by soaking in the circulating water of the fruit storage tank. During the lifting process, the tap water is sprayed and cleaned to reduce or eliminate microorganisms on the surface of the raw materials. Residual pesticides, soil, etc.; pick out mildew, apples and sundries that have deteriorated due to diseases and insect pests (leaves, twigs, packaging bags, weeds, ropes, etc.);

[0033] (2) Core removal and core washing The selected peaches enter the core removing machine to remove the core, and the separated core enters the core washing machine to wash the core, wash off the pulp on the core, and transport it into the crushing storage bucket, which can make full use of the peach fruit ...

Embodiment 2

[0047] Embodiment 2 A kind of production technology of concentrated peach clear juice, see figure 1 , including the following steps:

[0048](1) Cleaning and sorting Soak and clean the Okubo peaches in the circulating water of the fruit storage pool, and spray and clean them with tap water during the lifting process; pick out the apples and sundries that have deteriorated due to mildew, diseases and insect pests;

[0049] (2) Pitting and core washing The selected peaches enter the core removing machine to remove the core, and the separated core enters the core washing machine;

[0050] (3) Breaking and adding enzymes Break the pulp after denuclearization to a particle size of 5-10mm, and add 50-100mL of pulp enzyme and 10-30mL of pectinase to each ton of fruit pulp at the same time;

[0051] (4) Soften the pulp in the core by steam, add an appropriate amount of water to wash the core, and after the core washing water and pulp are collected, heat it to 49-54°C with a tubular h...

Embodiment 3

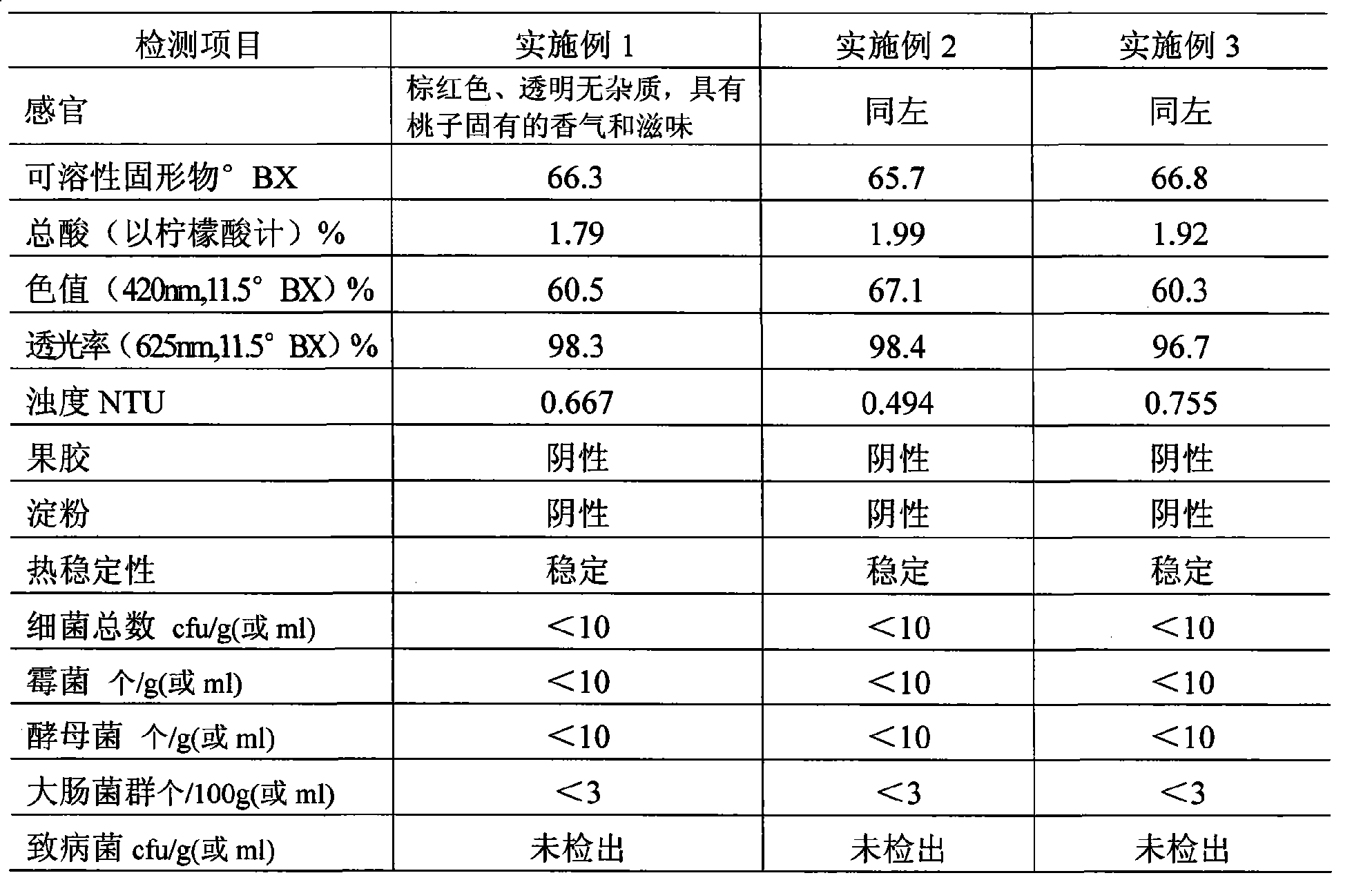

[0063] Embodiment 3 A kind of production technology of concentrated peach clear juice is basically the same as embodiment 1, the difference is: step (3) adds 55mL of pulp enzyme and 15mL of pectinase to every ton of fruit pulp; step (8) enzyme Cool the pre-pasteurized fruit juice to 50°C and enter the enzymatic hydrolysis tank. At the same time, add 40mL of pectinase and 30mL of amylase per ton of fruit juice, and do not add after enzymatic hydrolysis until the detection of pectin and starch shows "-". Activated carbon. The quality index of gained concentrated peach clear juice is shown in Table 1.

[0064] Table 1 Quality index of concentrated peach clear juice

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com