SMXP-58 strain for degrading pectin in tobacco leaves and application of SMXP-58 strain

A technology of SMXP-58 and tobacco leaves, which is applied to Bacillus sp. SMXP-58 strain and its application in tobacco leaf alcoholization, can solve problems such as tobacco smoking and adverse effects on safety, incomplete tobacco combustion, and impact on cigarette quality, Achieve the effect of good promotion and application value, improve tobacco leaf quality, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment only briefly introduces the screening and identification process of the SMXP-58 strain as follows.

[0023] The SMXP-58 strain was originally isolated from red-cured tobacco leaves produced in Sanmenxia in 2013. The colony is round or irregular on the NA culture plate, milky white, dull, the surface of the colony is flat or irregular folds and raised, the surface is rough and not smooth, and the colony is opaque. The shape under the oil mirror is as figure 1 As shown, the bacteria can be observed to be evenly distributed, rod-shaped, and rarely chain-shaped, with a size of (0.7~0.9)×(1.6~2)μm.

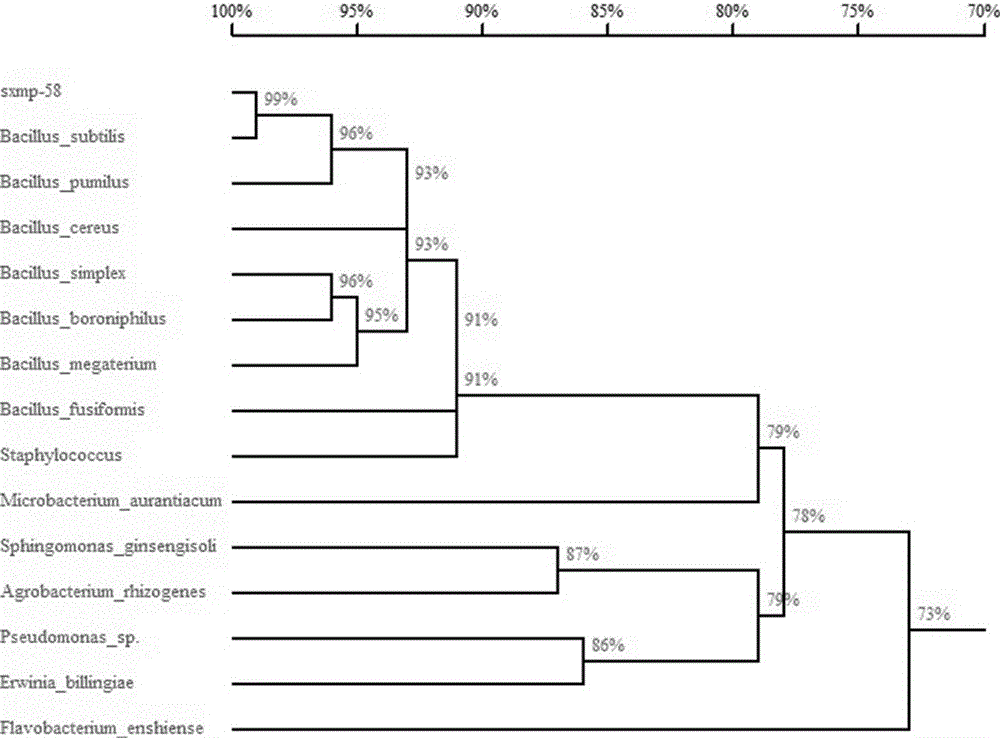

[0024] Using the 16S rDNA gene fragment as a general primer, the strain was subjected to PCR and cloning and sequencing, and a 1416bp sequence was obtained, and phylogenetic analysis showed that the strain SMXP-58 was closely related to Bacillus subtilis ( Bacillus subtilis ) has a homology of up to 99%, that is, the closest relationship with Bacillus subtili...

Embodiment 2

[0027] In order to use the SMXP-58 strain screened in Example 1 to degrade pectin in tobacco leaves, it is first necessary to prepare the strain into an easy-to-use bacterial agent. The specific preparation process is as follows.

[0028] (1) Activated strains: put the SMXP-58 strain on the LB plate, and cultivate it in a biochemical climate chamber at 37°C for 1-2 days;

[0029] (2) Preparation of seed liquid: Scrape the bacteria cultured in step (1) in the ultra-clean workbench, inoculate in a 18×180 test tube containing 5 mL of liquid LB medium, and place on a shaker at 30°C and 150 rpm Overnight culture;

[0030] (3) Expansion culture: Transfer the seed solution in step (2) to a sterile 250mL Erlenmeyer flask containing 100mL liquid LB medium at the ratio of 1 mL bacterial suspension / 100 ml LB medium (1% volume ratio) medium, 30°C, 150 rpm, cultured to OD 600 = about 2.0;

[0031] (4) Preparation of bacterial agent: Centrifuge the bacterial solution in step (3) at 3600 ...

Embodiment 3

[0033] When utilizing bacterial agent prepared in embodiment 2 to process tobacco leaves, concrete steps are:

[0034] When treating the tobacco leaves, use a sprayer to evenly spray the above bacterial agents on the surface of the tobacco leaves, then adjust the moisture content of the tobacco leaves to 25%; finally place them in a constant temperature and humidity box at 30°C (the tobacco leaves after spraying the bacterial agents are placed in a sealed bag, and then placed in a Fermentation in a constant temperature and humidity box under dark conditions, so its humidity is not affected by the humidity in the constant temperature and humidity box), fermentation treatment for 60~84h; Inactivate.

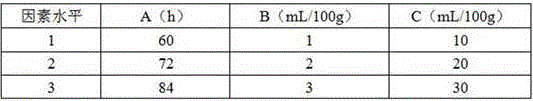

[0035] In order to determine the optimal usage ratio between the bacterial agent and the tobacco leaf material, the inventor further carried out an orthogonal experimental screening, and the related experimental process is briefly introduced as follows.

[0036] Tobacco leaf sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com