Rotor untwisting toothed plate with low feeding resistance

A tooth plate and rotor technology, applied in the field of cellulose fiber preparation, pulping and papermaking, can solve the problems of easy broken teeth, high service life, high power consumption, and unsmooth feeding, so as to adjust the length of cellulose fibers, improve the The beating degree and yield, the effect of improving the degree of brooming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

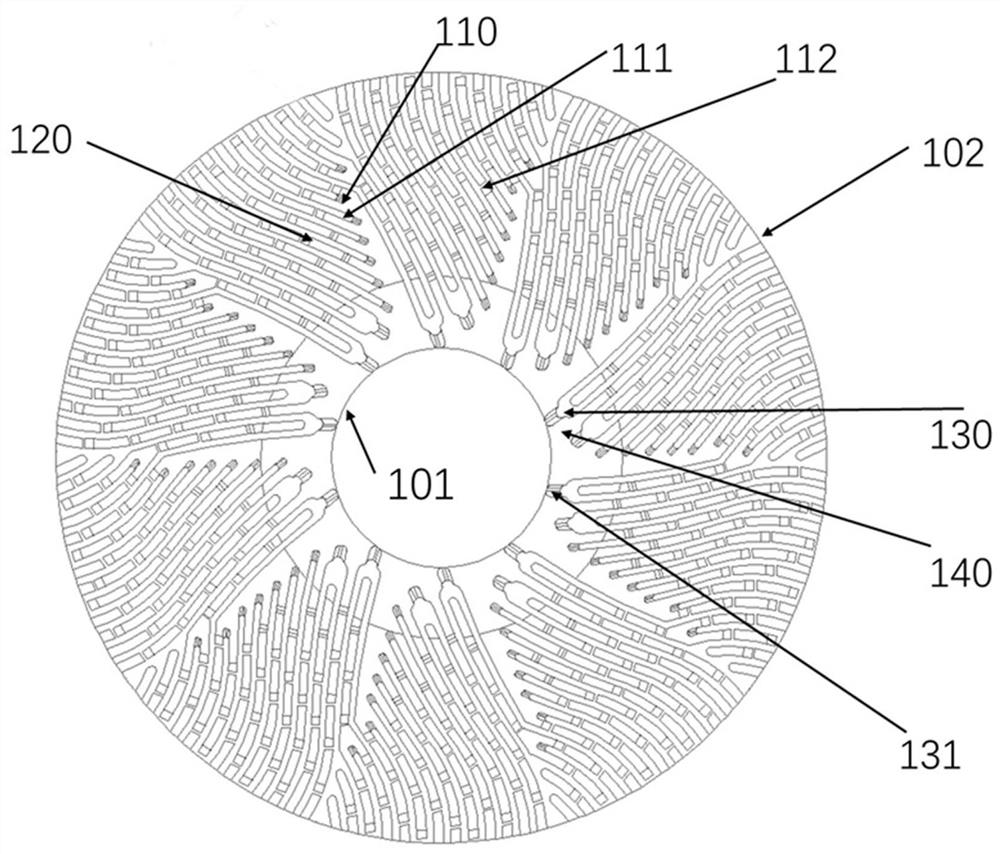

[0021] Such as figure 1 As shown, a rotor deflaking tooth plate with low feed resistance, the rotor deflaking tooth plate is installed on the rotating seat of the deflaking machine, and the rotor deflaking tooth plate is used to cooperate with the stator deflaking tooth plate of the static seat of the deflaking machine.

[0022] The rotor decompression tooth plate faces the stator decompression tooth plate and is set in a plane contact manner, non-engaging, so it can work under the condition of a lower clearance, and has the functions of improving the decomposition and crushing of cellulose fibers, adjusting the length of cellulose fibers, and wear resistance. It has the advantages of high strength, good impact resistance, not easy to break teeth, long service life and saving power consumption.

[0023] There are 10 rack units distributed in the circumferential direction of the rotor loosening tooth plate, and the rack unit is arranged between the inner edge 101 and the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com