Preparation method for high-strength poplar veneer

A poplar veneer, high-strength technology, used in wood treatment, impregnating wood, manufacturing tools, etc., can solve problems such as poor mechanical properties and limited application scope, achieve modified mechanical properties, increase total free energy, and improve porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

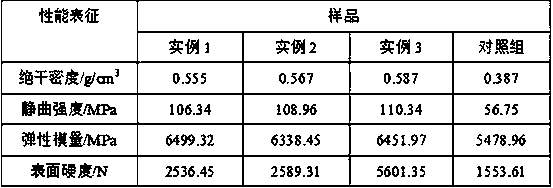

Examples

example 1

[0019] Take a poplar veneer with a thickness of 2mm, dry it at 65°C until the moisture content is 8%, polish the surface of the poplar veneer with water-resistant sandpaper, and then dry it at 100°C to constant weight to obtain a dry poplar veneer. board, take the dry poplar veneer and place it at 105°C for pre-steaming for 10 minutes, collect the steamed veneer and soak the steamed veneer until the mass fraction of 2% xylanase solution is placed in the After soaking in a beaker at 35°C for 6 hours, take the impregnated poplar veneer and rinse it with deionized water for 3 times, and dry it in vacuum to obtain the enzymatically modified poplar veneer; Put 45 parts of deionized water, 3 parts of peach gum, and 2 parts of sugar alcohol in a beaker, and ultrasonically disperse at 200W for 10 minutes to obtain a dispersion coating solution; apply the dispersion coating solution evenly to the enzymatically modified poplar veneer On the surface, the coating thickness is controlled t...

example 2

[0021] Take a poplar veneer with a thickness of 2mm, dry it at 67°C until the moisture content is 9%, polish the surface of the poplar veneer with water-resistant sandpaper, and then dry it at 105°C to constant weight to obtain a dry poplar veneer. board, take the dry poplar veneer and place it at 105°C for pre-steaming for 12 minutes, collect the steamed veneer and soak the steamed veneer until the mass fraction of 2% xylanase solution is placed in the After soaking in a beaker at 37°C for 7 hours, take the impregnated poplar veneer, rinse it with deionized water for 4 times, and dry it in vacuum to obtain the enzymatically modified poplar veneer; Put 47 parts of deionized water, 4 parts of peach gum, and 2 parts of sugar alcohol in a beaker, and ultrasonically disperse at 250W for 12 minutes to obtain a dispersion coating solution; apply the dispersion coating solution evenly to the enzymatically modified poplar veneer On the surface, the coating thickness is controlled to b...

example 3

[0023] Take a poplar veneer with a thickness of 2mm, dry it at 70°C until the moisture content is 10%, polish the surface of the poplar veneer with water-resistant sandpaper, and then dry it at 110°C to constant weight to obtain a dry poplar veneer. board, take the dry poplar veneer and place it at 105°C for pre-steaming for 15 minutes, collect the steamed veneer and soak the steamed veneer until the mass fraction of 2% xylanase solution is placed in the After soaking in a beaker at 40°C for 7 hours, take the impregnated poplar veneer, rinse it with deionized water for 5 times, and dry it in vacuum to obtain the enzymatically modified poplar veneer; Put 50 parts of deionized water, 5 parts of peach gum, and 3 parts of sugar alcohol in a beaker, and ultrasonically disperse at 300W for 15 minutes to obtain a dispersion coating solution; apply the dispersion coating solution evenly to the enzymatically modified poplar veneer On the surface, the coating thickness is controlled to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com