Patents

Literature

33results about How to "Reduce water absorption rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

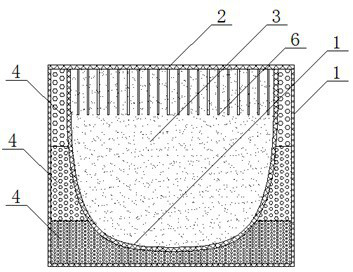

Recycled concrete and production technology thereof

The invention discloses a recycled concrete and a production technology thereof. The recycled concrete is prepared from, by weight, 100-112 parts of coarse aggregates, 68-75 parts of fine aggregates,27-33 parts of cement, 15-22 parts of a mineral admixture, 5-10 parts of fibers, 3-8 parts of rubber particles, 13-19 parts of water and 0.6-1.0 part of an admixture; the coarse aggregates include modified recycled coarse aggregates and ordinary coarse aggregates, and the recycled coarse aggregates are obtained by modifying waste concrete particles with a nano-material and silica sol as modifiers;and the fine aggregates include recycled fine aggregates and ordinary fine aggregates. The production technology improves the compressive strength, the flexural strength and the drying shrinkage of concrete, and improves the flexural property, the impermeability, the corrosion resistance, the impact resistance and the wear resistance of concrete. The preparation method of the recycled concrete includes the following steps: detection, metering, mixing, stirring and curing. The preparation method of the invention has the advantages of simple production process, safety in operation, and easinessin implementation.

Owner:四川衡鼎建材有限公司

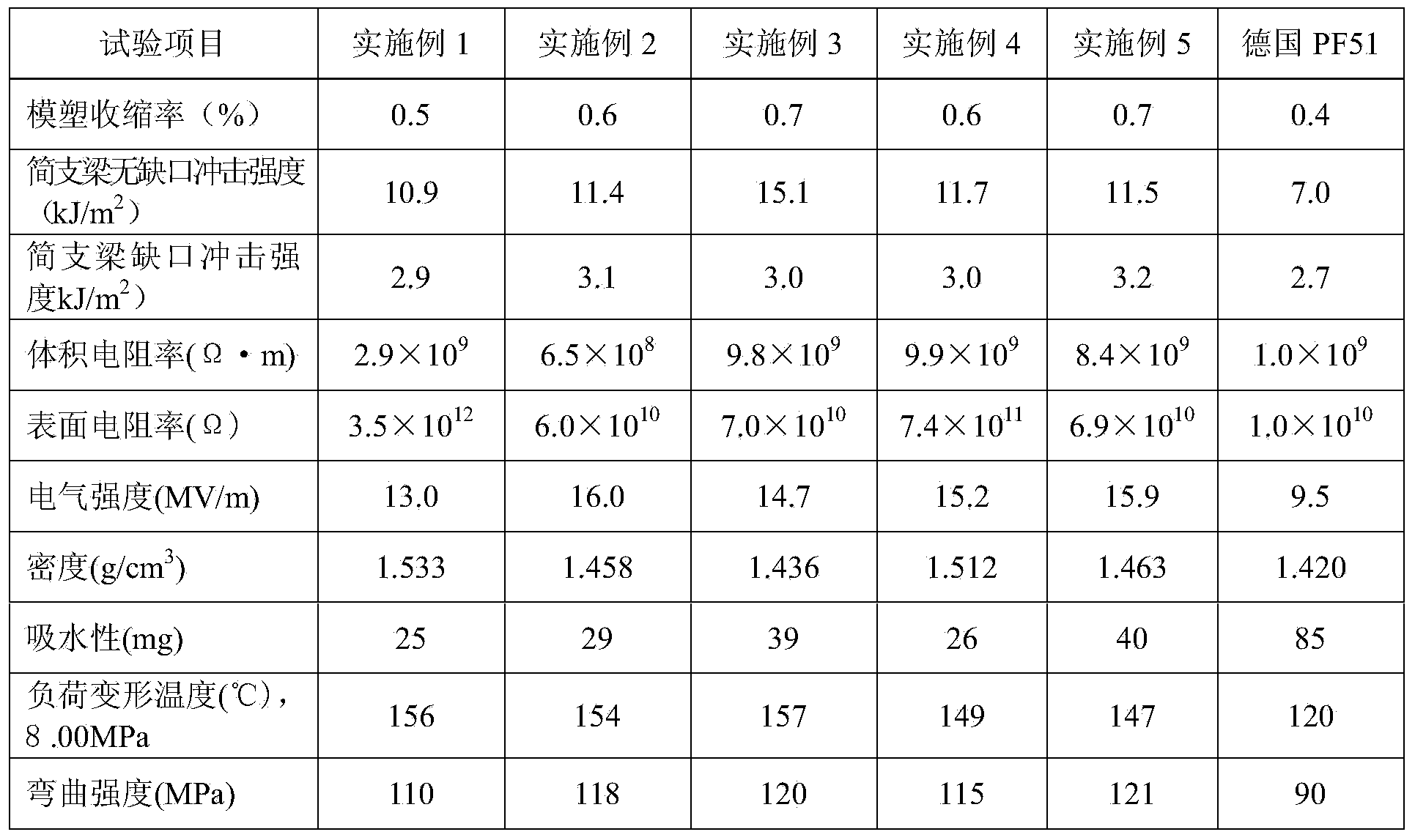

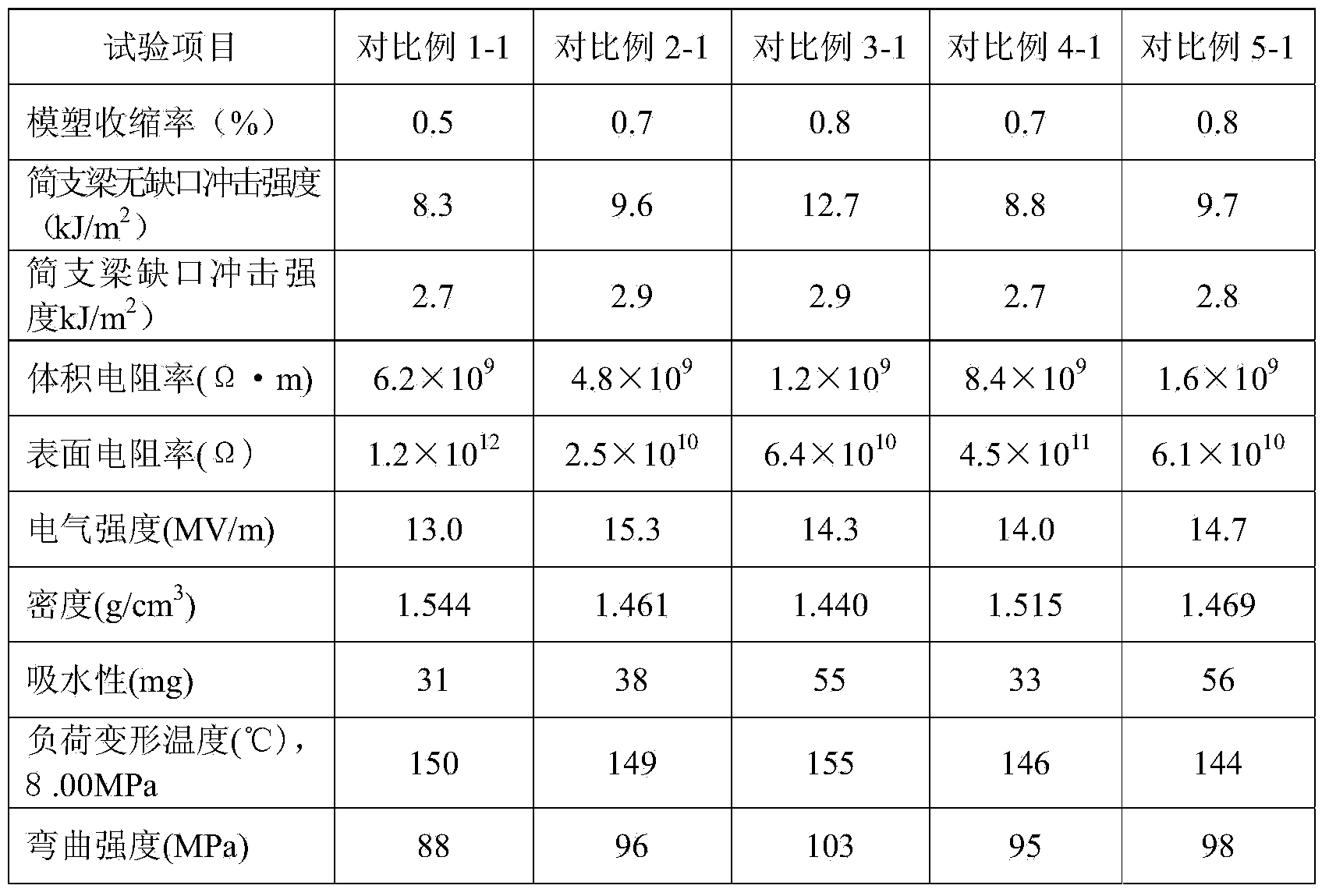

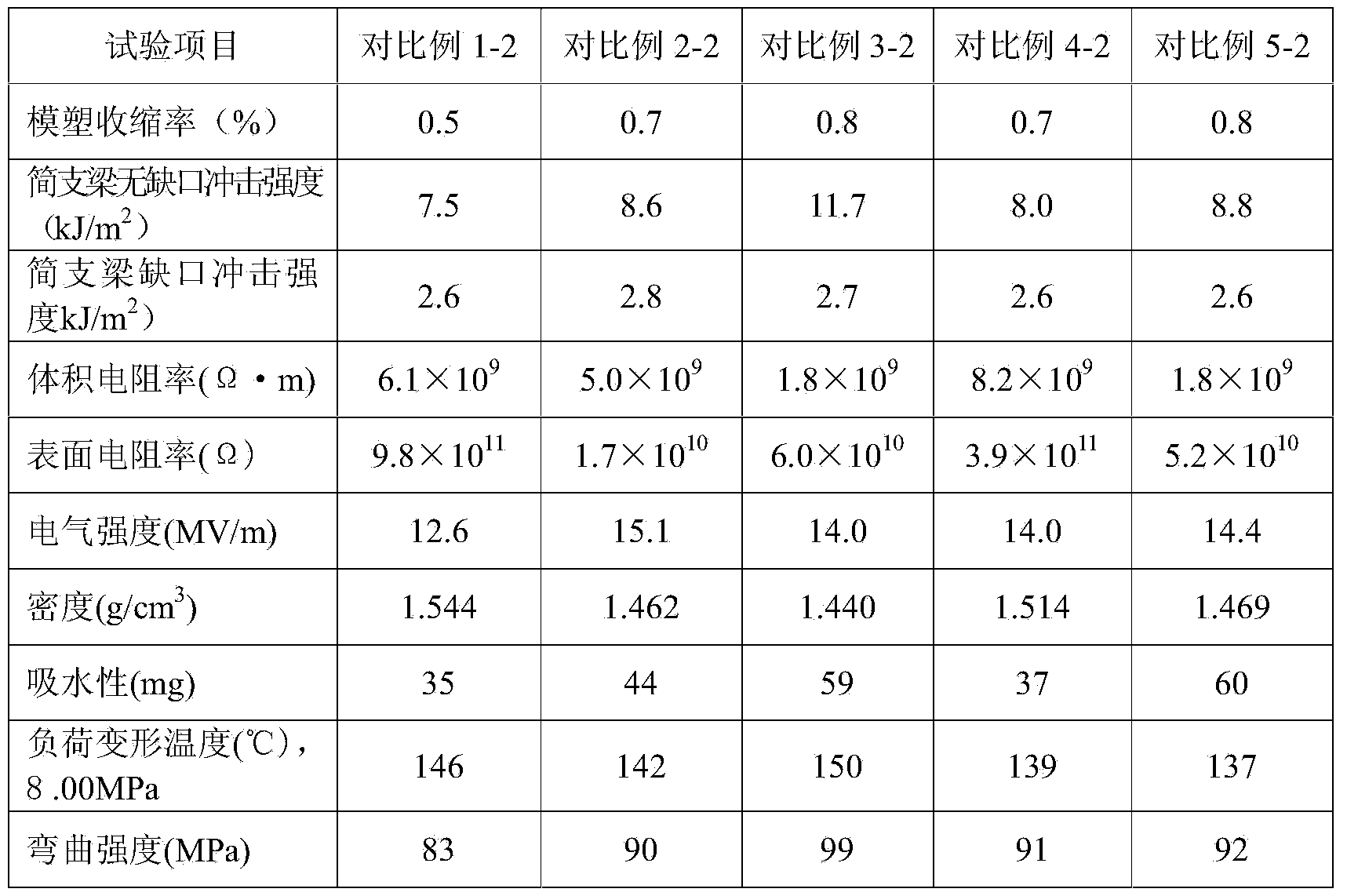

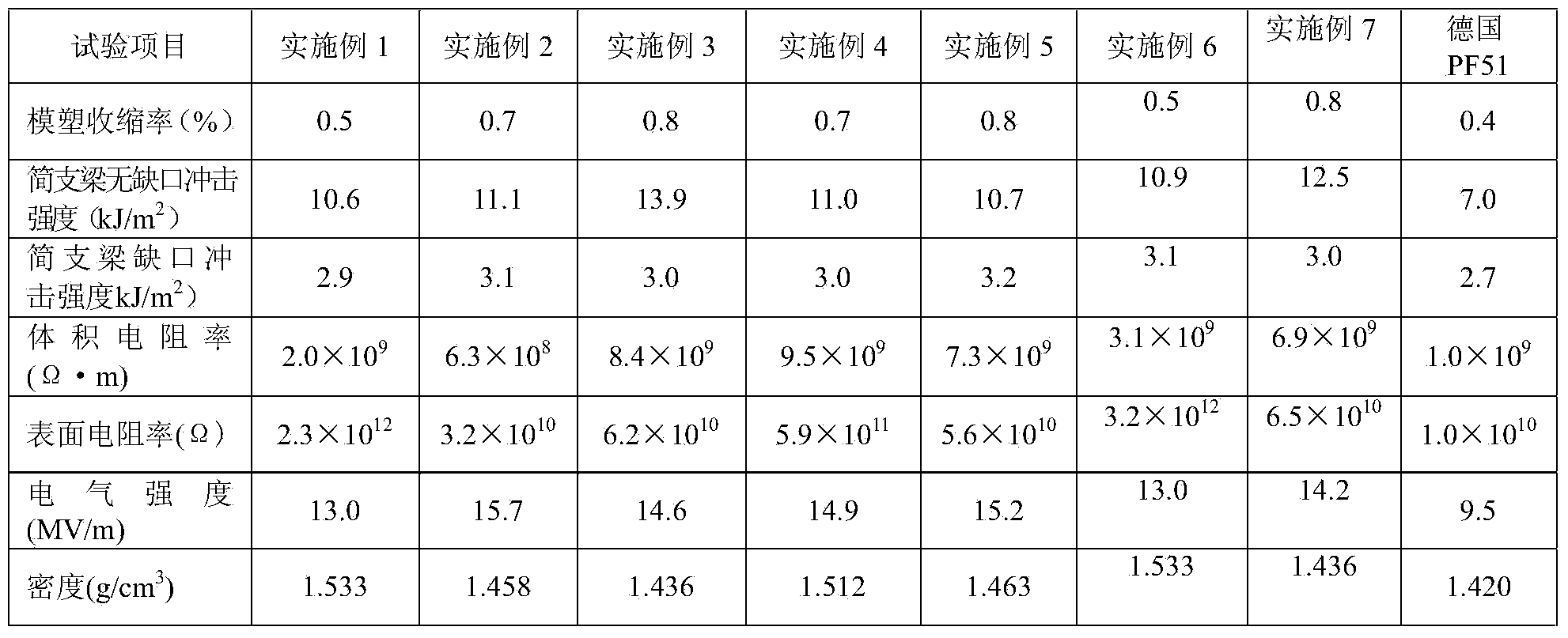

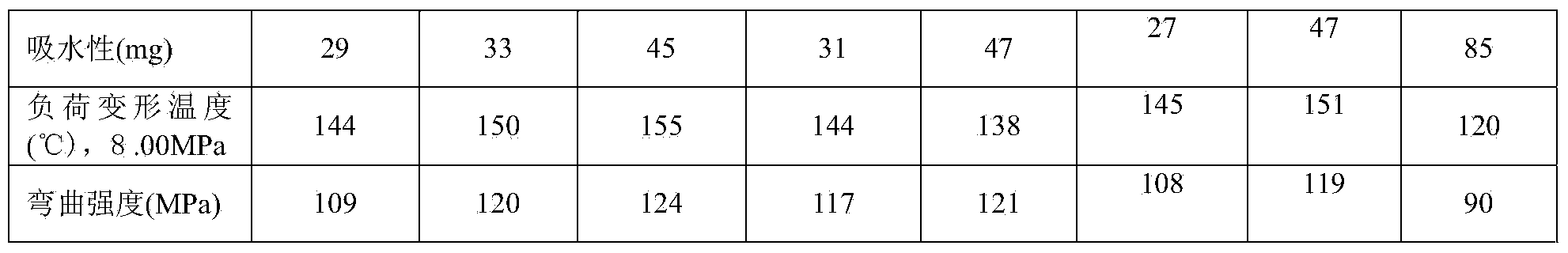

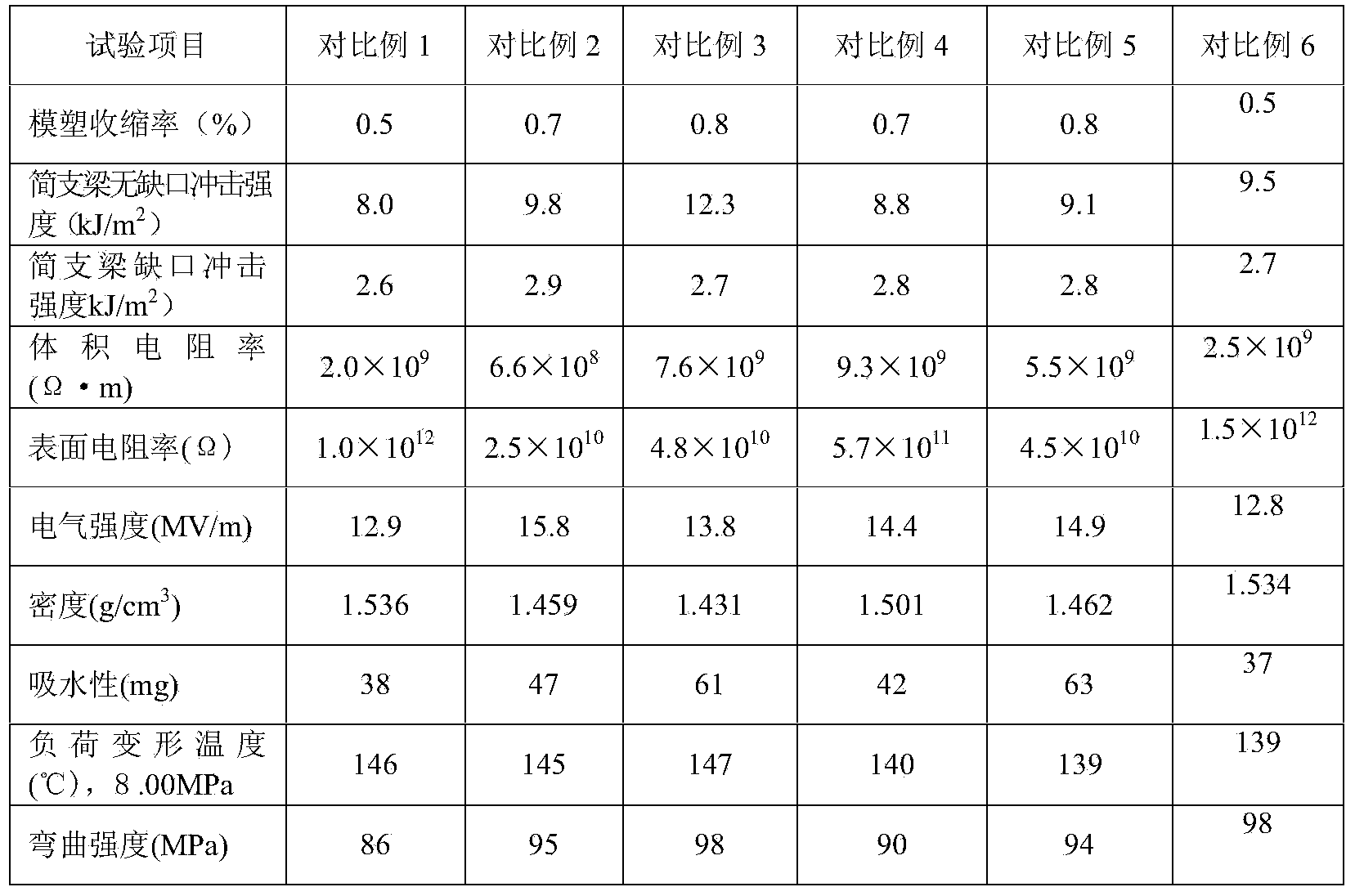

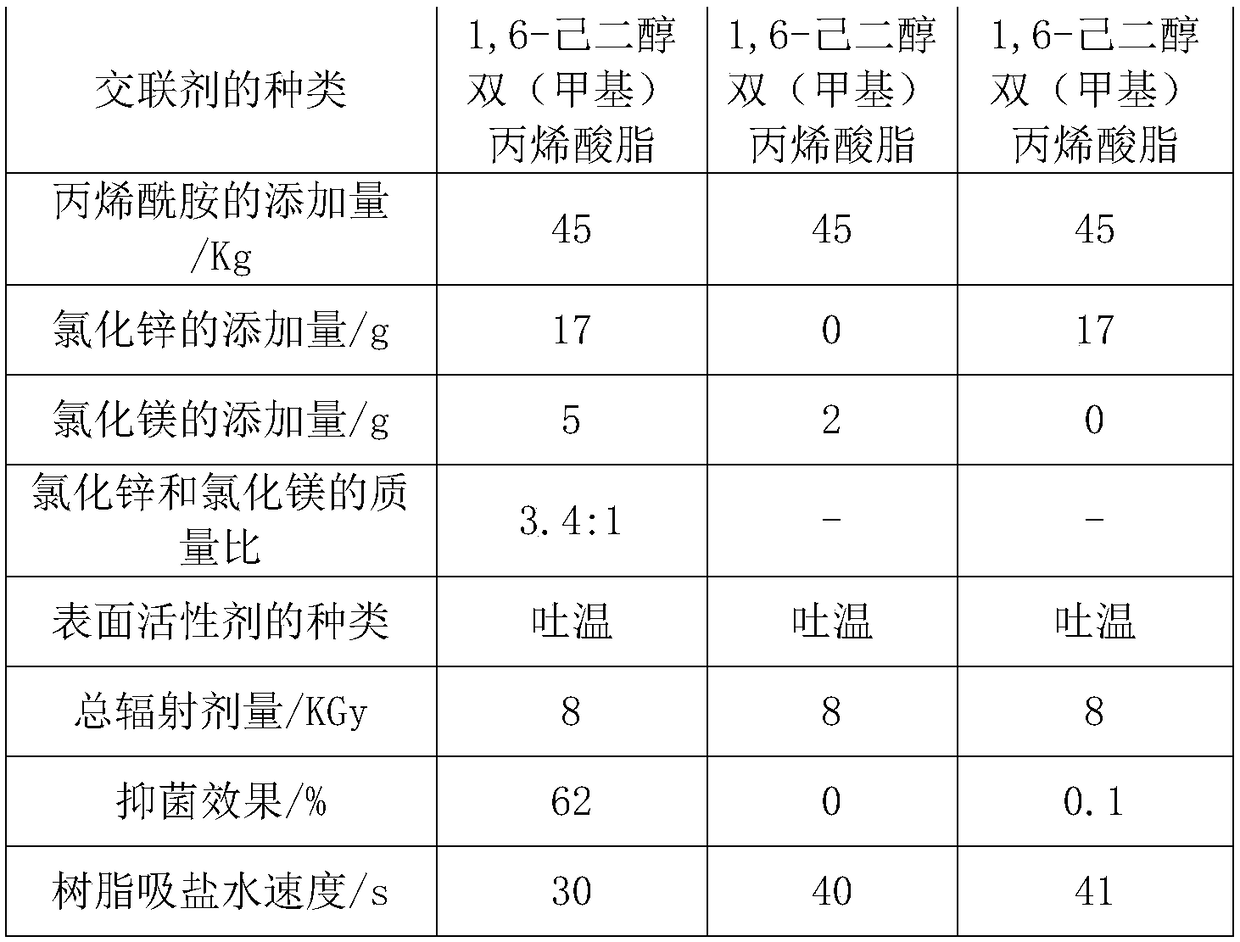

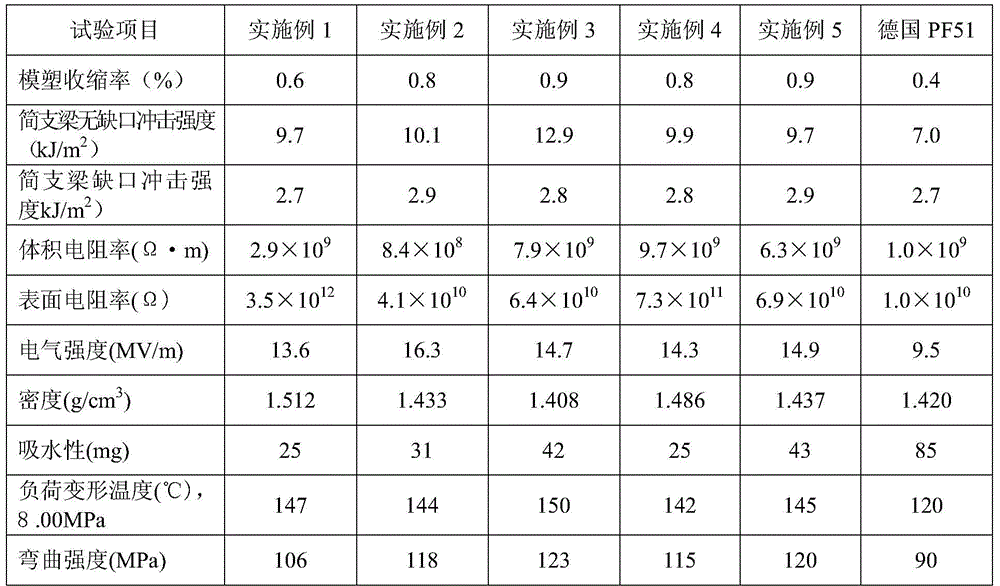

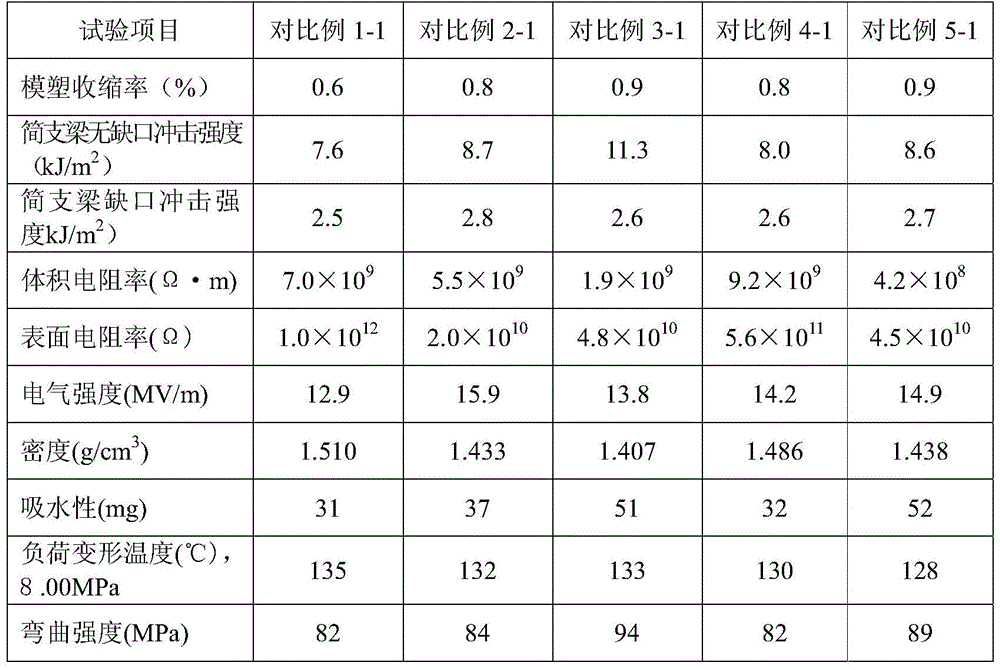

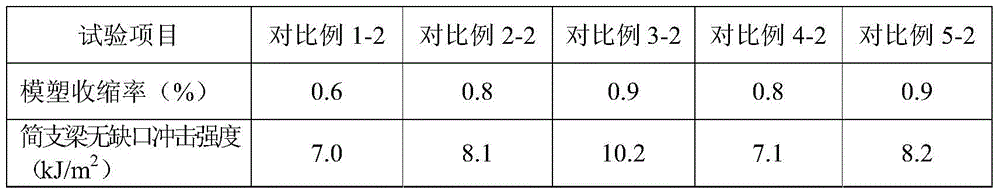

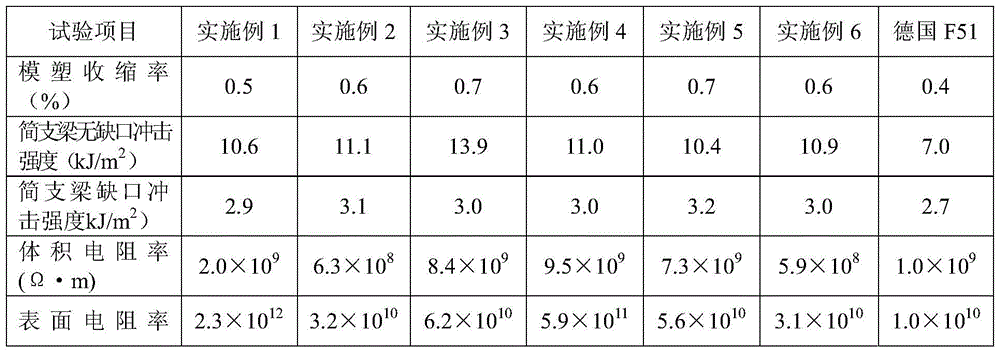

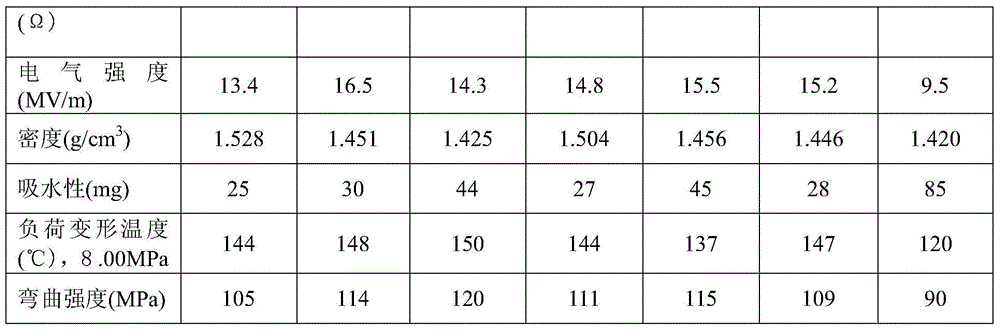

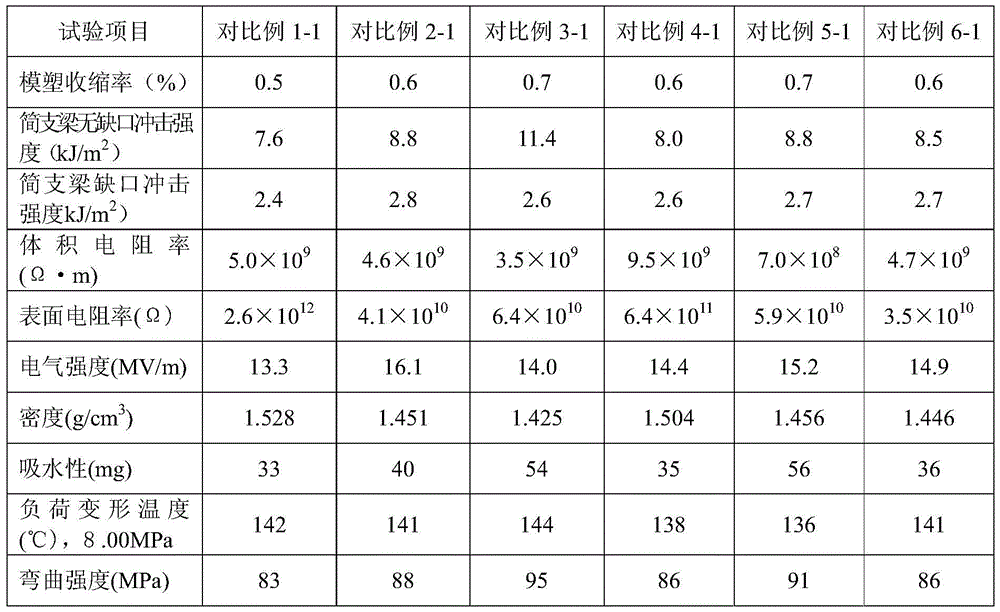

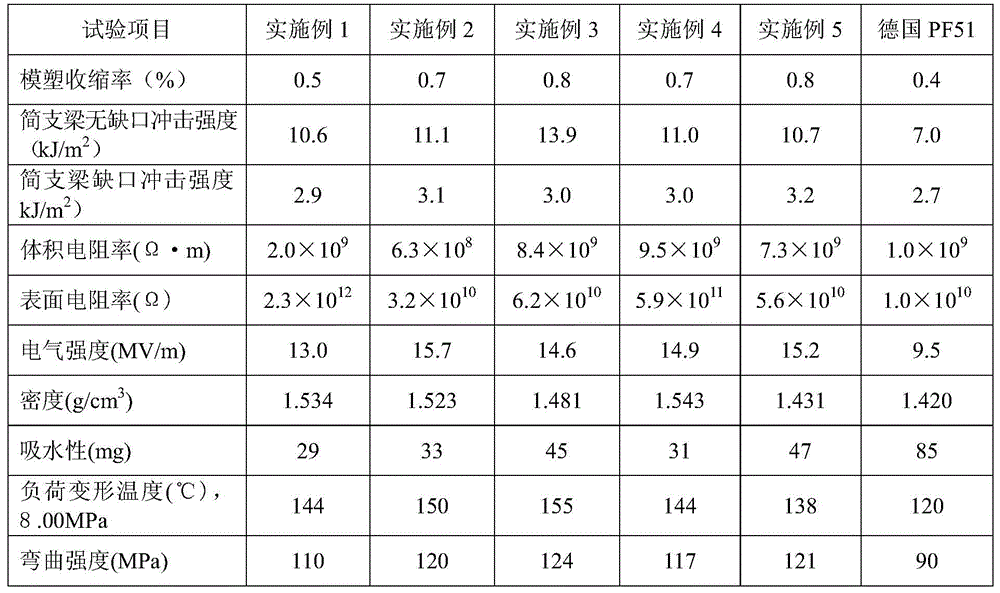

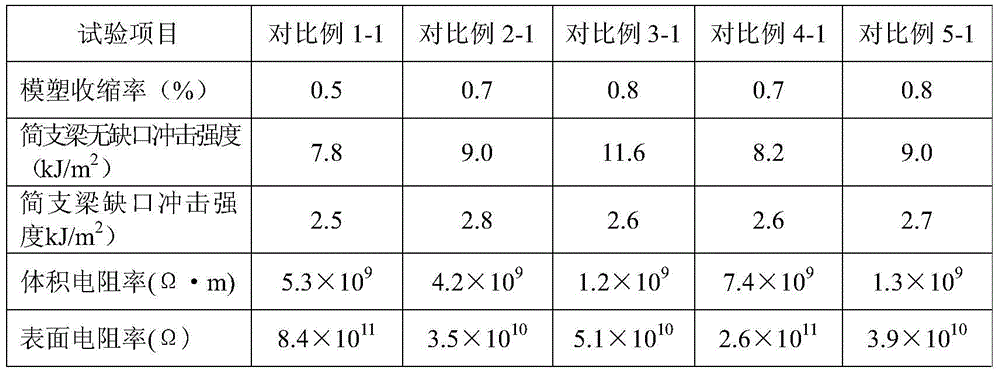

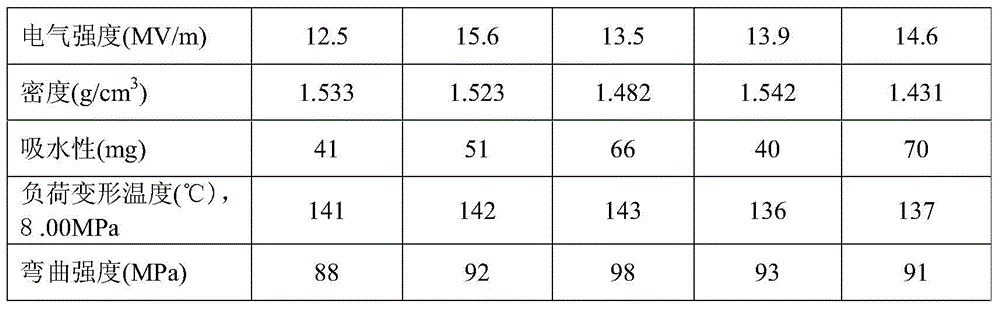

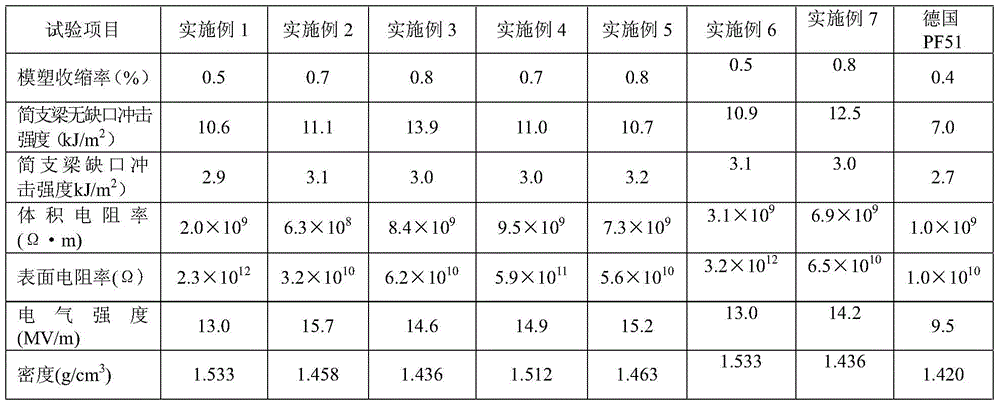

Carbon fiber reinforced injected phenolic moulding plastic and preparation method thereof

The invention discloses a carbon fiber reinforced injected phenolic moulding plastic and a preparation method thereof. The phenolic moulding plastic is mainly prepared from novolac resin, hexamethylenetetramine, inorganic fillers and carbon fibers. The preparation method comprises the following steps: (1) weighing the raw materials for later use; (2) performing uniform ball-milling on the inorganic fillers and a coupling agent in a ball mill or a ball-milling tank, wherein the usage amount of the coupling agent accounts for 0.5wt%-10wt% that of the inorganic fillers, and the inorganic fillers are selected from one or combination of two or more of aluminum hydroxide, silica powder, calcite, talcum, calcium carbonate, glass beads, kaolin and argil powder; (3) grinding hexamethylenetetramine and uniformly mixing with the inorganic fillers and other raw materials subjected to surface treatment to obtain a mixture; (4) extruding the mixture in a double-screw extruder to obtain an extruded material; and (5) cooling and grinding the extruded material to obtain the phenolic moulding plastic. The phenolic moulding plastic prepared by adopting the method is relatively high in mechanical property and relatively low in water absorptivity.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

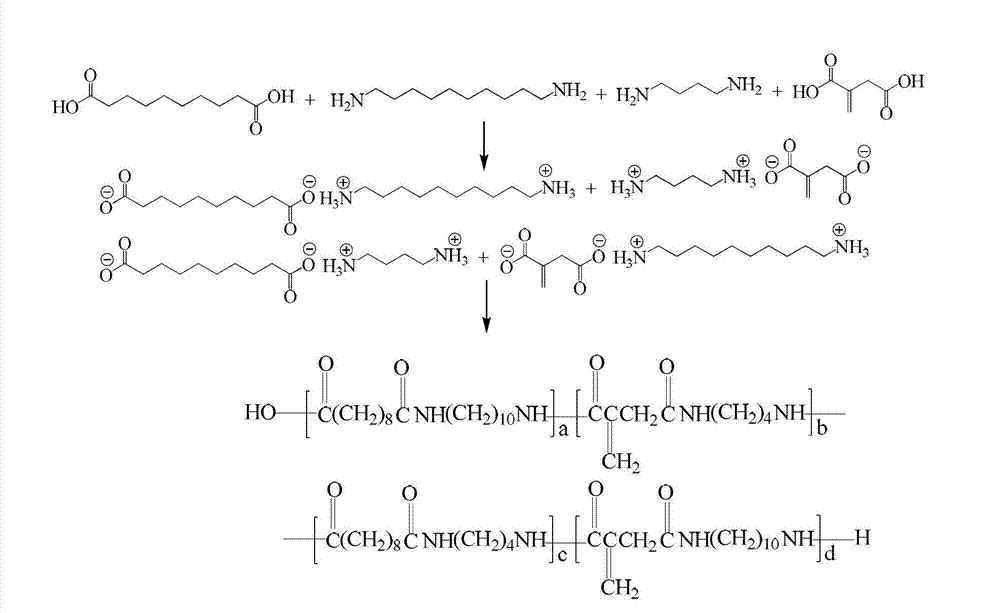

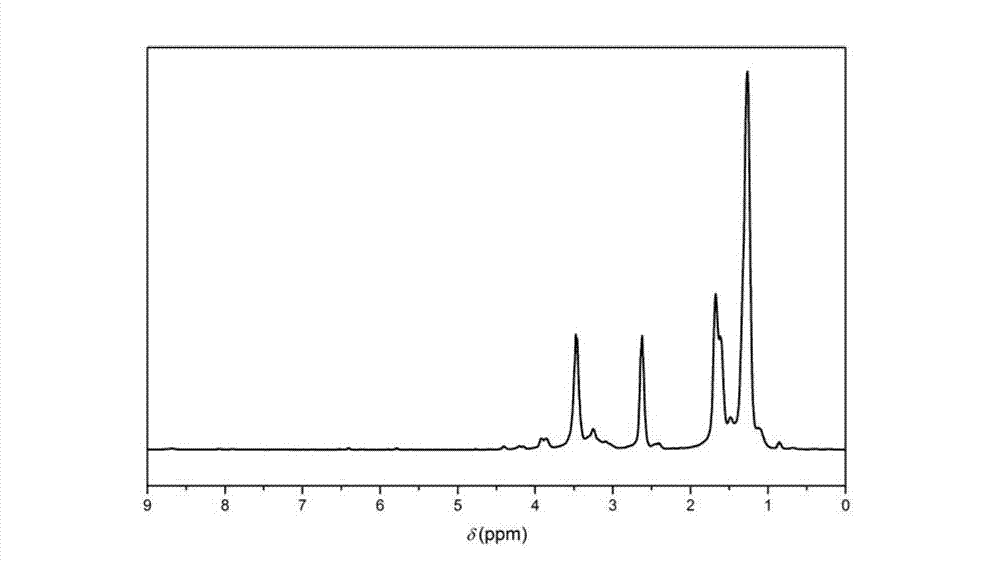

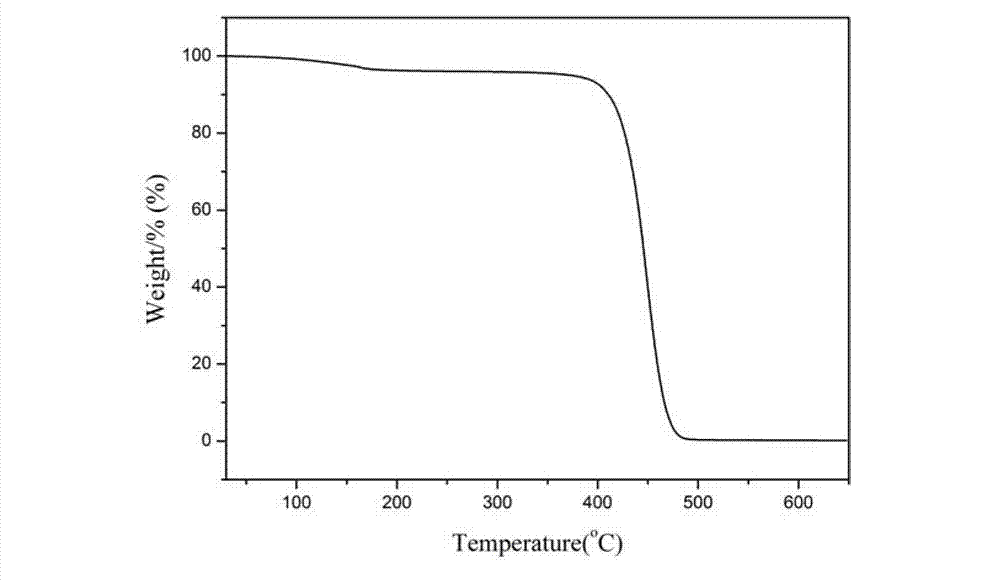

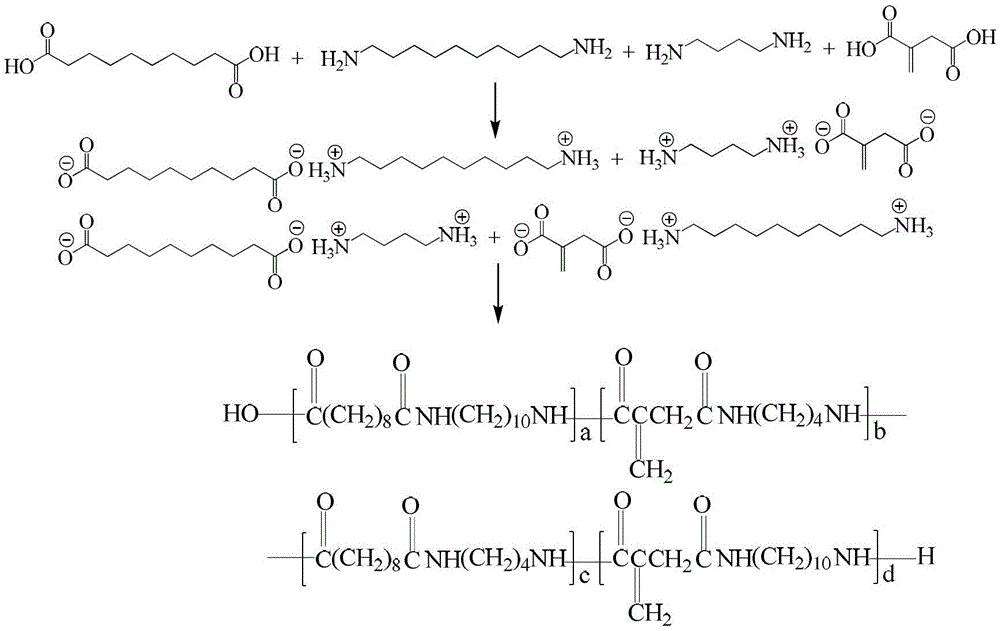

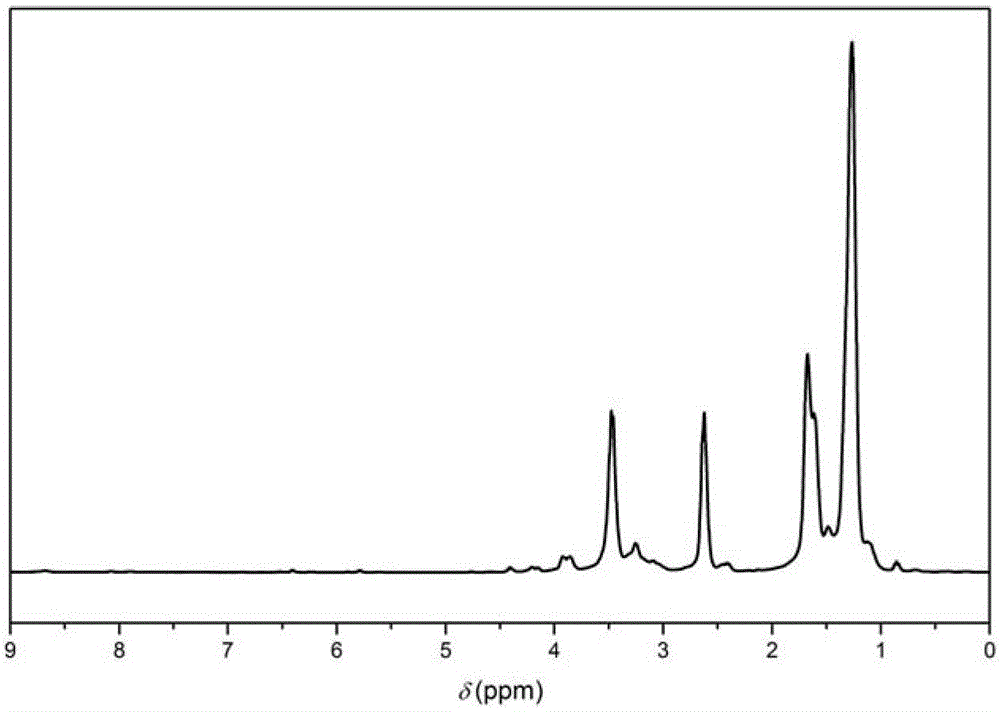

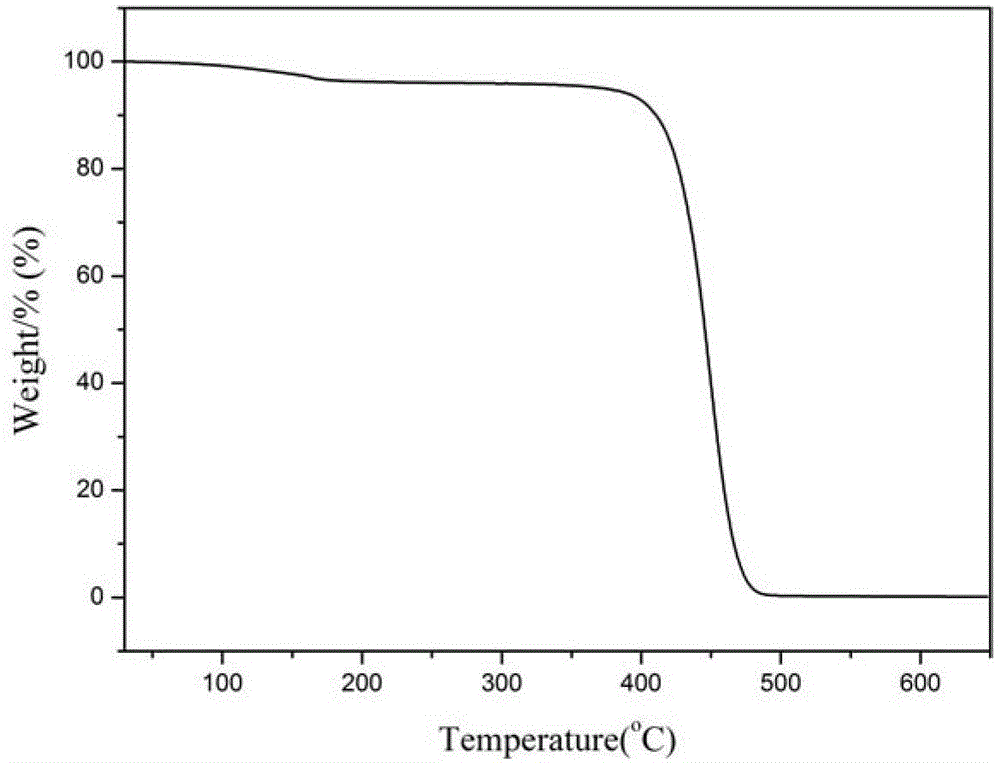

Biologic polyamide quadripolymer and synthesis method thereof

ActiveCN103030803AGood environmental stabilityReduce the degradation ratePolymer scienceSynthesis methods

The invention relates to a biologic polyamide quadripolymer and a synthesis method thereof, and belongs to the field of high molecular materials. The biologic polyamide quadripolymer is characterized in that the structural formula is shown as the specifications, wherein the four chain segments or chain links are arranged randomly. The invention also provides the synthesis method. The biologic polyamide quadripolymer has excellent environmental stability, a thermal crosslinking property, an irradiation crosslinking property and solvent corrosion resistance, and has physical and mechanical properties and a processing property which are equal to those of conventional polyamide.

Owner:BEIJING UNIV OF CHEM TECH

Antibiotic degradable water retaining agent and preparation method thereof

The invention belongs to the field of polymer materials, and concretely discloses an antibiotic degradable water retaining agent and a preparation method thereof. The water retaining agent is prepared from acrylic acid, acrylamide, long-chain quaternary ammonium salt, kaolin and sodium alginate through a redox system aqueous solution polymerization technology with ammonium persulfate or potassium persulfate as an oxidant, sodium bisulfite as a reducing agent and N,N-methylenebisacrylamide as a cross-linking agent. Acrylic acid is neutralized with ammonia water or ammonium bicarbonate, so the problem of soil hardening induced by long-term application of a sodium base water retaining agent to soil is avoided, and nutrients are provided. Kaolin with low price and wide sources and biodegradable sodium alginate are introduced to a copolymerization system, so the preparation cost of the water retaining agent is effectively reduced, and the gelly strength, the water absorption rate, the salt resistance and the biodegradability of the water retaining agent are improved. A wide-spectrum antibiosis material is also introduced, so storage of the degradable water retaining and further prolongation of the service life of the water retaining agent are facilitated. The antibiotic degradable water retaining agent can be widely applied in the fields of agriculture, forestry, gardening, ecologic construction and desert treatment.

Owner:ZHONGKAI UNIV OF AGRI & ENG

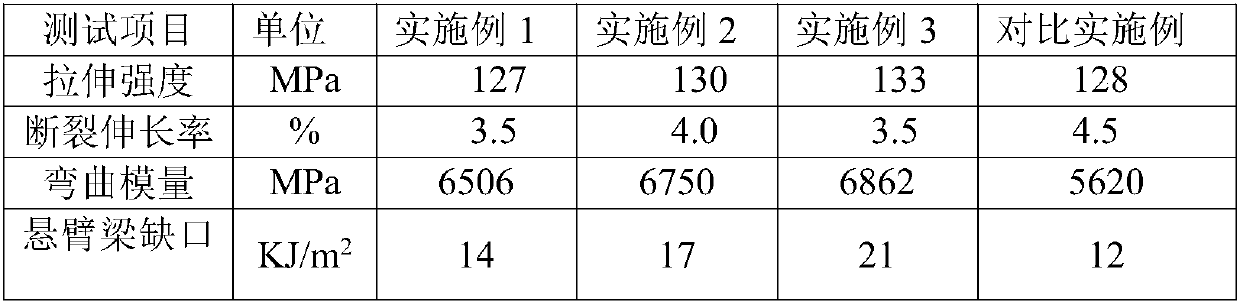

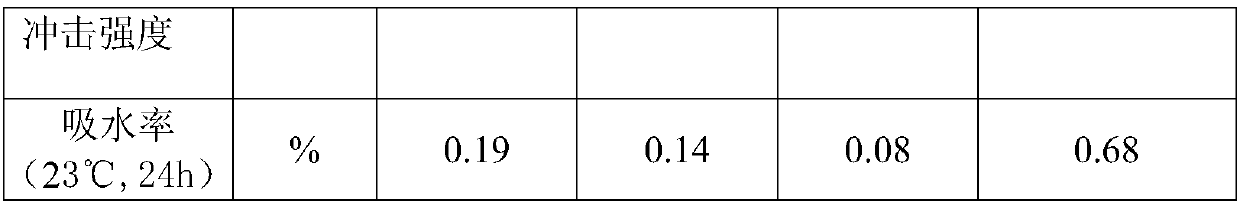

High-rigidity low-water-absorption nylon 6 composite material

The invention discloses a high-rigidity low-water-absorption nylon 6 composite material. The high-rigidity low-water-absorption nylon 6 composite material is characterized by being prepared from the following raw materials in parts by weight: 100 to 120 parts of nylon 6, 10 to 30 parts of barrier, 3 to 5 parts of nano montmorillonite, 30 to 50 parts of alkali-free glass fibers, 1 to 2 parts of silane coupling agent solution, 3 to 5 parts of nano layered silicate, 5 to 10 parts of acrylonitrile-butadiene-styrene-terpolymer, 1 to 10 parts of polytetrafluoroethylene, 3 to 5 parts of toughening agent, 1 to 5 parts of compatilizer, 0.1 to 1 part of heat resisting agent, 0.1 to 1 part of antioxidant, and 0.1 to 1 part of lubricating agent. The high-rigidity low-water-absorption nylon 6 compositematerial can still keep good rigidity in a water environment.

Owner:厦门德丰行塑胶工业有限公司

Preparation method of cotton-fiber-reinforced injection-type phenol aldehyde molding compound

The invention discloses a preparation method of a cotton-fiber-reinforced injection-type phenol aldehyde molding compound. The phenol aldehyde molding compound is mainly prepared from linear phenol aldehyde resin, hexamethylenetetramine, inorganic filler and cotton fiber. The preparation method comprises the following steps: 1) weighing the raw materials for later use; 2) putting the inorganic filler and coupling agent in a ball mill or ball milling tank, and carrying out uniform ball milling, wherein the coupling agent accounts for 0.5-10 wt% of the inorganic filler, and the inorganic filler is one or combination of more than two of aluminum hydroxide, silicon micropowder, calcite, talcum, calcium carbonate, glass microballoon, kaolin and ceramic powder; 3) pulverizing the hexamethylenetetramine, and uniformly mixing with the surface-treated inorganic filler and the other raw materials; 4) adding the mixture into a double screw extruder, and extruding; and 5) cooling the extruded stock, and pulverizing. The phenol aldehyde molding compound prepared by the method has the advantages of higher mechanical properties and lower water absorptivity.

Owner:桂林金格电工电子材料科技有限公司

Health-care fresh-keeping biscuits capable of assisting in lowering blood glucose and production method thereof

InactiveCN104304379AImprove antioxidant capacityPromote decompositionDough treatmentMetabolism disorderExtensibilityMitragyna rotundifolia

The invention provides health-care fresh-keeping biscuits capable of assisting in lowering blood glucose and a production method thereof. The biscuits comprise the following raw materials in weight%: cake flour 55-75%, extract of Prunus dulcis leaf 1.5-3%, extract of myrica rubra leaf 0.5-2%, extract of Streblus asper Lour. leaf 0.5-2%, extract of Mitragyna rotundifolia leaf 0.5-2%, Atriplex triangularis powder 2-5%, Trichosanthes kirilowii maxim seed oil 5-7%, pectin powder 1.5-3%, isomaltitol 5-7%, dried skim milk 1.5-3%, bamboo salt 0.3-0.5%, partridge eggs 6-9%, and instant dry yeast 0.7-1.5%. The raw materials are properly processed and prepared into the biscuits and have strong synergistic effect, thus the biological hypoglycemic activities of the extracts are higher than the simply superimposed biological hypoglycemic activities of the extracts, and the stability, the extensibility, the toughness and the machinability of dough are improved, so that the biscuits are well shaped and not easily broken, have bright color, low absorption rate and long fresh-keeping period, and are intense in fruit aroma and good in taste, and regular intake of the biscuits can assist in controlling and even lowering the blood glucose.

Owner:陆建益

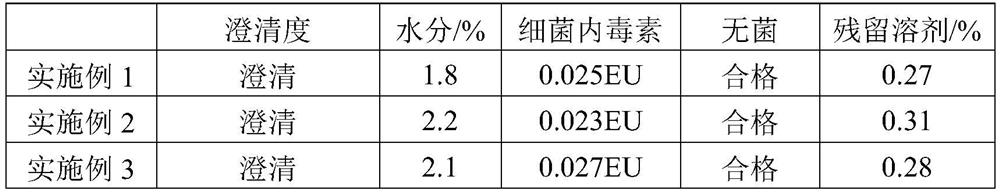

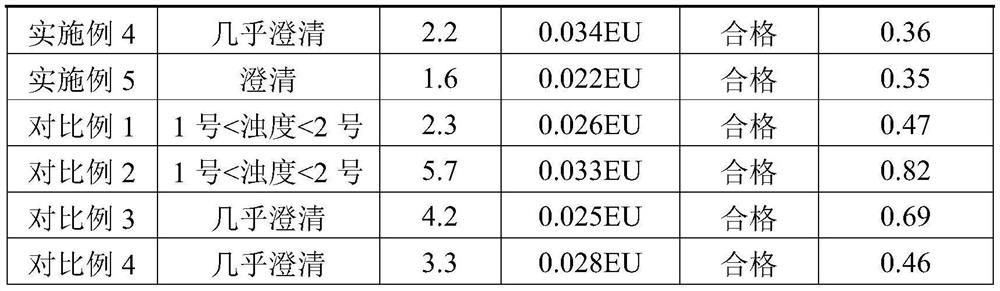

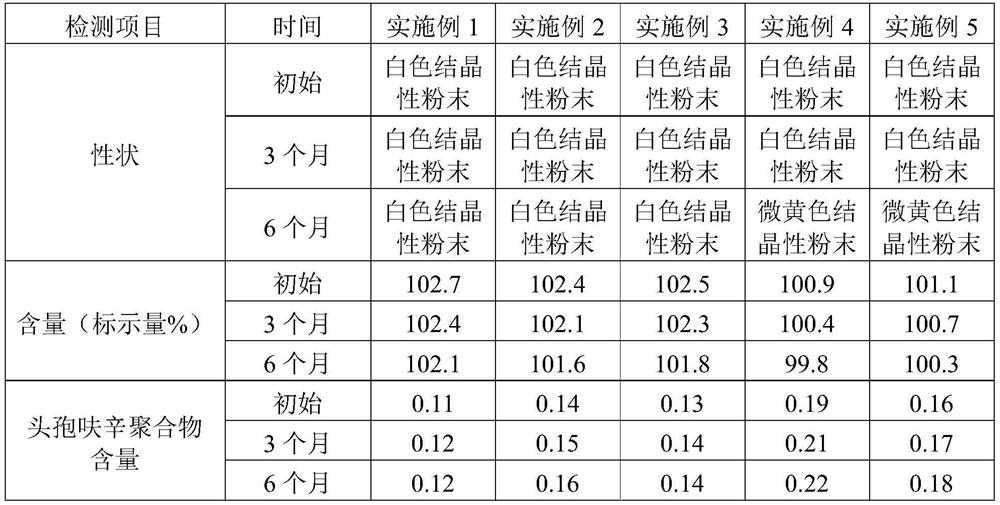

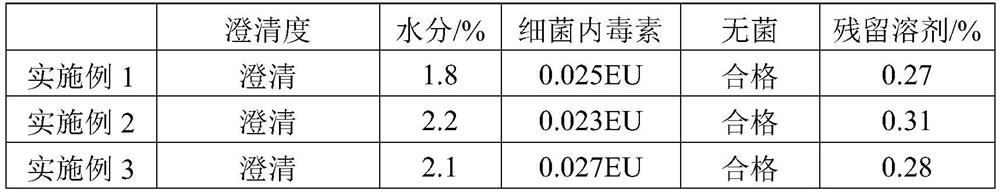

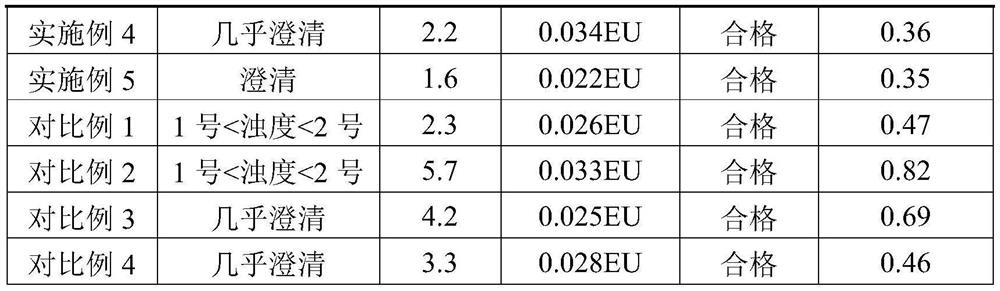

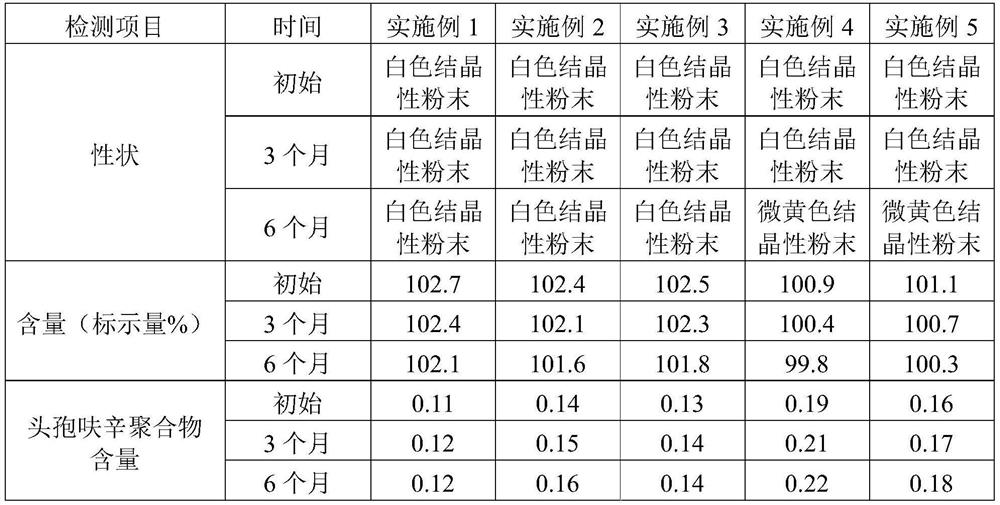

Preparation process of cefuroxime sodium for injection

The invention provides a preparation process of cefuroxime sodium for injection. The preparation process comprises the following steps: dissolving cefuroxime sodium in a phosphate buffer solution, conducting decolorizing with activated carbon, washing a filter cake with water to remove impurities in the cefuroxime sodium and prevent the cefuroxime sodium from being degraded in a decolorizing process, then adding seed crystals, resin and acetone into the cefuroxime sodium solution for crystal growing, and increasing the proportion of the acetone by utilizing the water absorption performance of the resin to absorb water in the solution in a crystallization process so as to improve the crystallization effect of the cefuroxime sodium, reduce residual water in the crystal form and improving the stability of the cefuroxime sodium for injection. According to the invention, pressurizing treatment is carried out once at set intervals, so when crystallization reaches a bottleneck, the water absorption of the resin and the solubility of the cefuroxime sodium can be changed, and the separation of cefuroxime sodium crystals is promoted.

Owner:HAINAN HAILING CHEMIPHARMA CORP

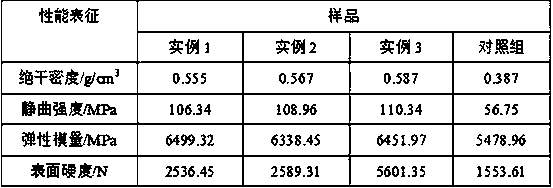

Preparation method for high-strength poplar veneer

InactiveCN107553643AIncrease bulkImprove the degree of filamentationWood treatment detailsCoating impregnationFiberFree energies

The invention relates to a preparation method for a high-strength poplar veneer and belongs to the technical field of laminate materials. After the poplar veneer is soaked with xylanase, the bulk of the material is effectively improved, the devillicate degree of fiber is improved, the specific surface area of the fiber is enlarged, the tightness of the veneer material is improved, the voidage in veneer tissue is reduced, the surface pores of the poplar plank material are effectively improved, meanwhile, sugar alcohol can permeate cell walls of the material through diffusion, and the veneer hygroscopicity is reduced and the cell walls are enhanced through furfuryl alcohol resin solidified in the cell walls in chaff alcoholizing manner; by means of the blockage effect, the water absorptionrate of the cell walls and the deformation-recovery rate are delayed, and the mechanical performance of the material is effectively improved; the step of veneer sanding is a pretreatment step, the total free energy of the surface of the immersed and compressed veneer can be obviously increased through sanding treatment, peach gum can be effectively adsorbed, by cooperating with enzymolysis, the peach gum material permeates into the cell walls, and the mechanical performance of the modified composite veneer material is effectively improved.

Owner:吴刚

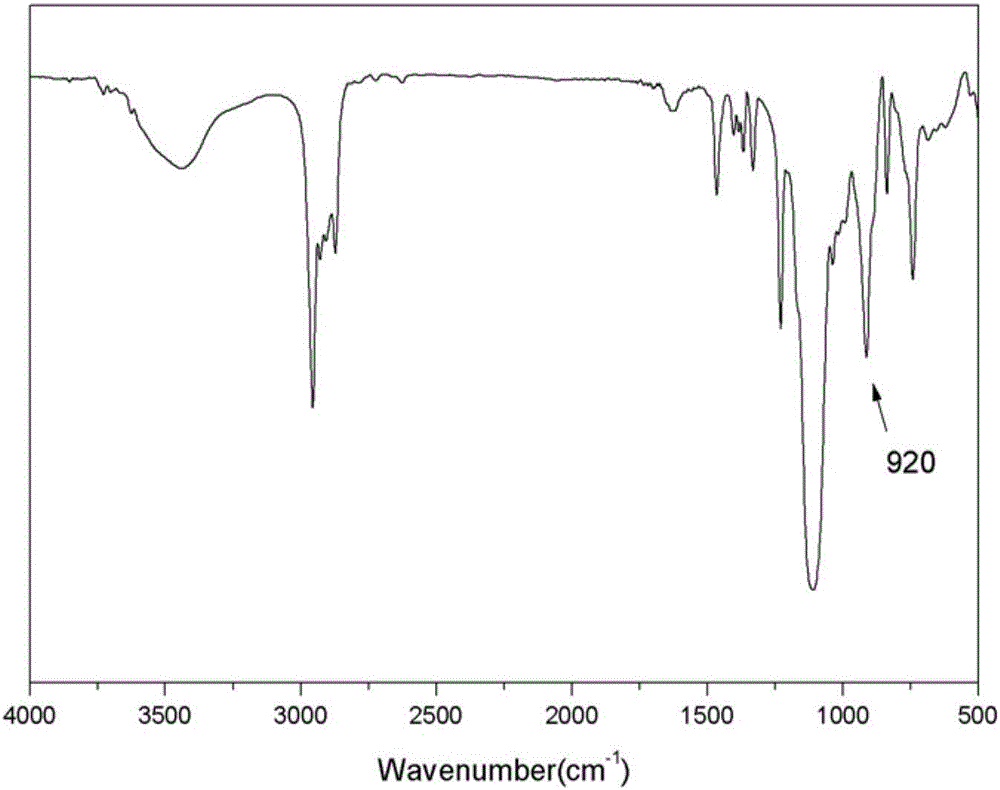

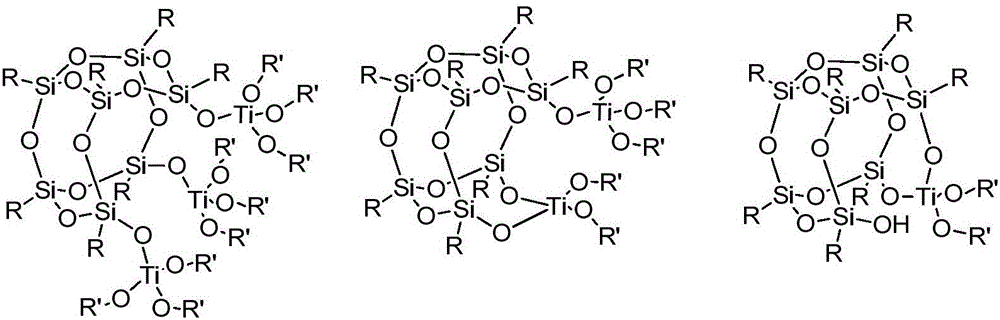

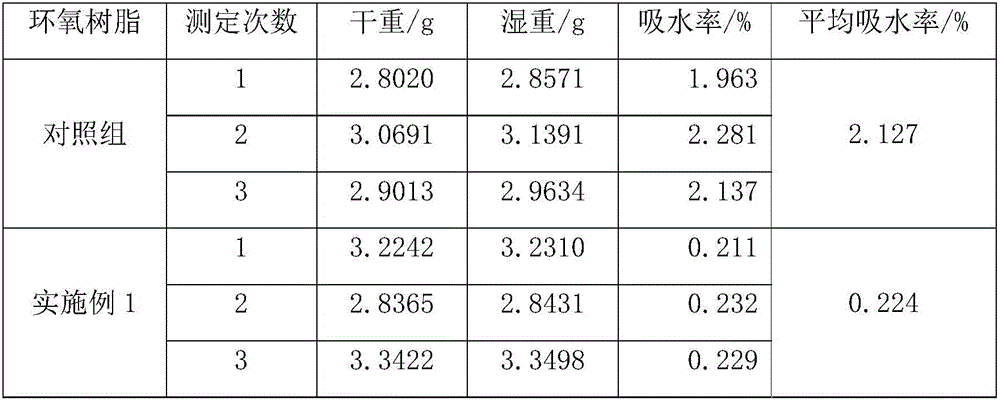

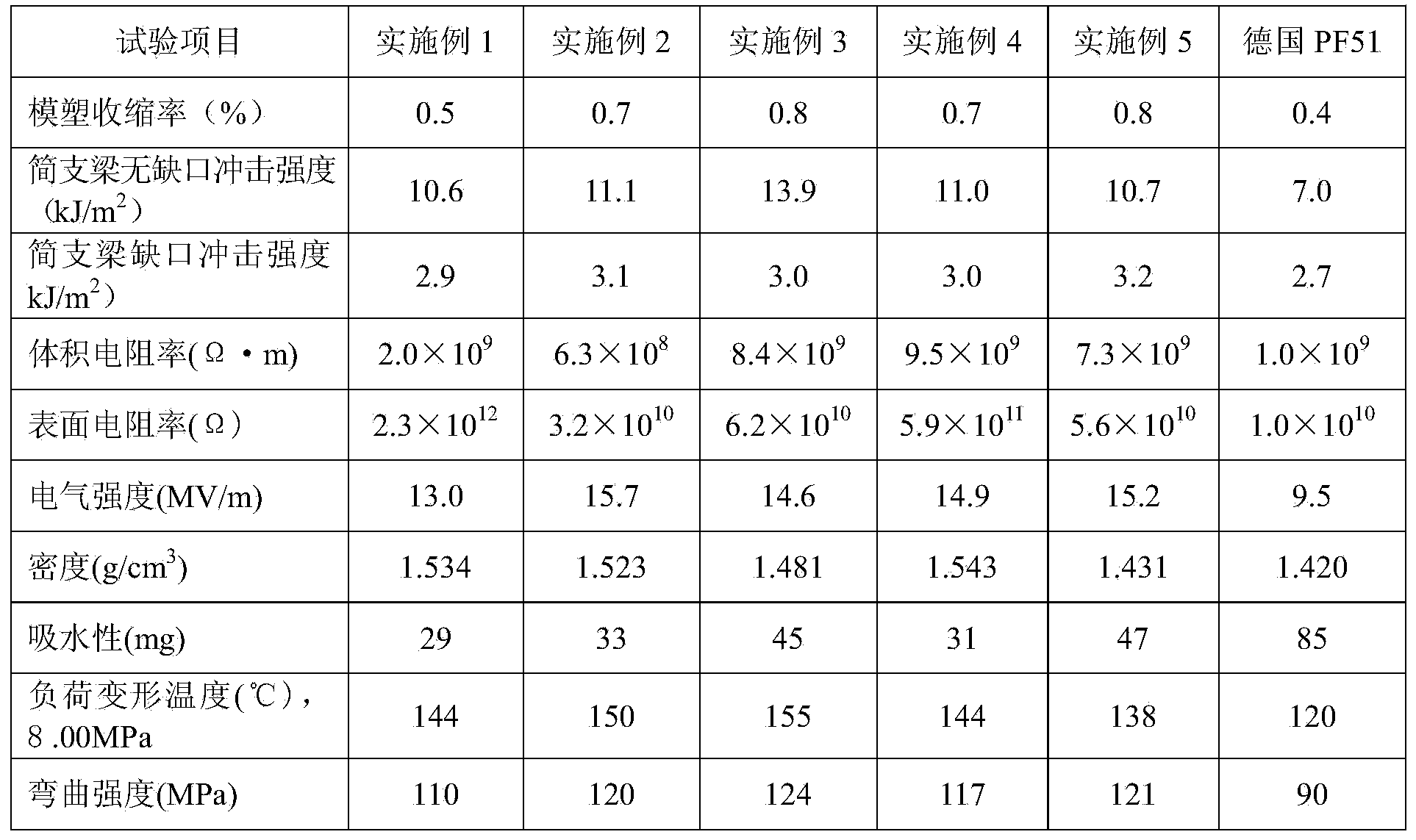

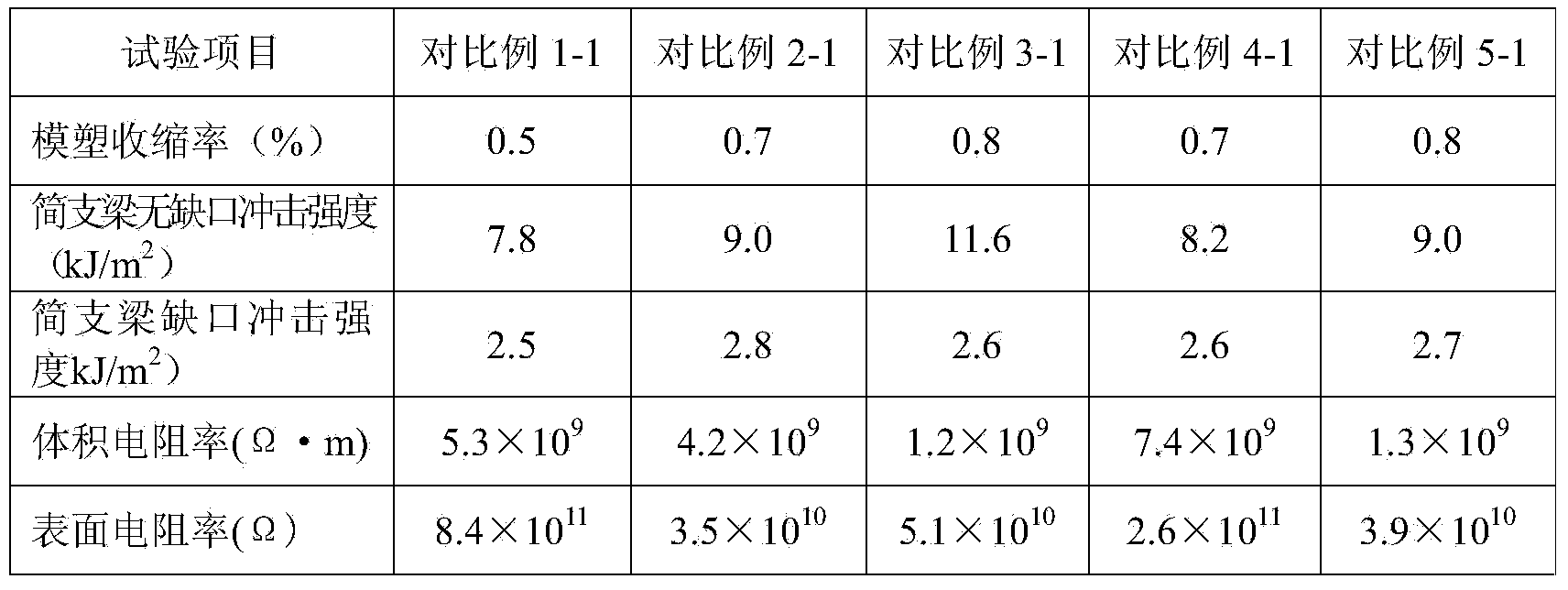

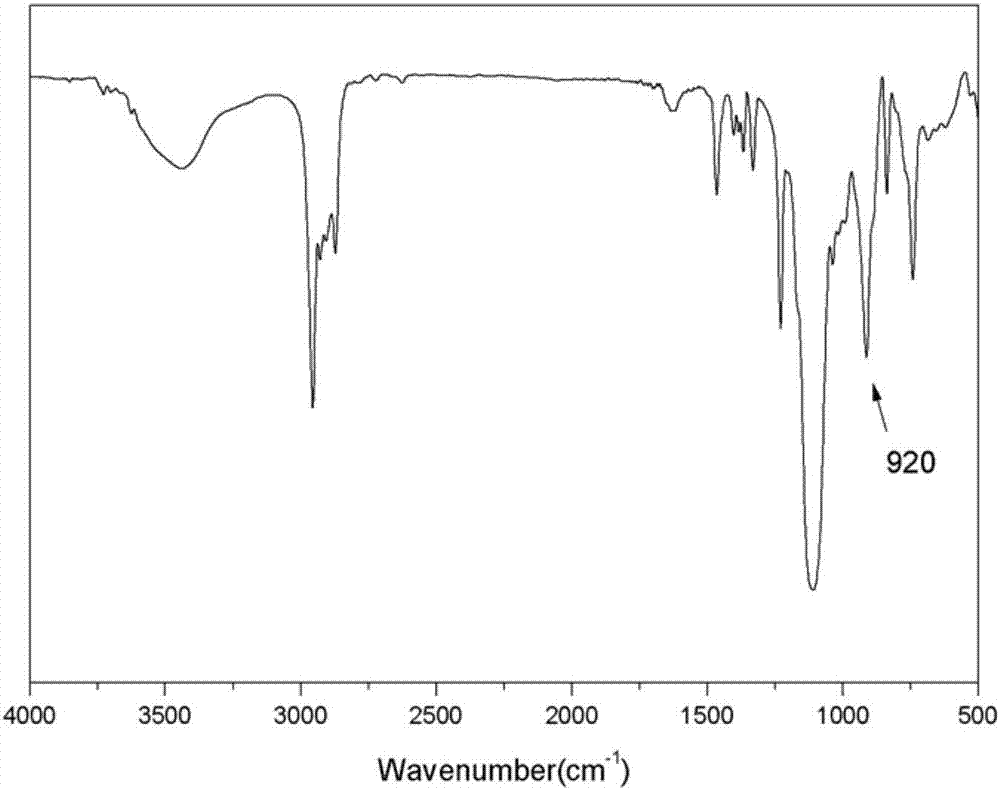

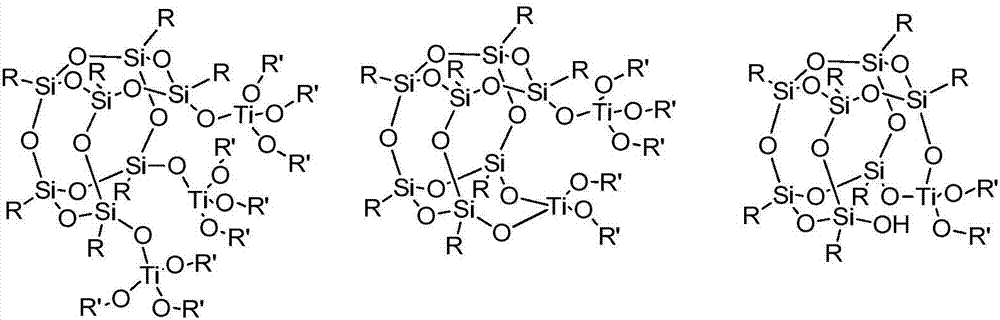

Low-hygroscopicity epoxy resin and preparation method thereof

The invention discloses low-hygroscopicity epoxy resin and a preparation method thereof and relates to epoxy resin. The low-hygroscopicity epoxy resin consists of epoxy resin, a curing agent and organic titanium hybrid silsesquioxane, wherein the dosage of the organic titanium hybrid silsesquioxane is 1-20% of that of the epoxy resin by mass; and the dosage of the curing agent is in a stoichiometric ratio to the epoxide equivalent of the epoxy resin. The preparation method comprises the following steps: putting the epoxy resin into a container and heating and stirring; adding organic titanium hybrid silsesquioxane for reacting while performing vacuum suction of small molecules; adding the curing agent; stirring uniformly and pouring into a preheated mould; curing for 4h at 120-130 DEG C; preserving heat for 2h at 130-150 DEG C; and finally, preserving heat for 2h at 150-170 DEG C, and molding to obtain the low-hygroscopicity epoxy resin. The water absorption of the epoxy resin is reduced, and the crosslinking density of the resin is increased; and meanwhile, the mechanical property and heat resistance of the epoxy resin are improved, and the barrier performance of the epoxy resin is enhanced.

Owner:XIAMEN UNIV

Nylon fiber reinforced injectable phenolic moulding plastic and preparation method thereof

The invention discloses nylon fiber reinforced injectable phenolic moulding plastic and a preparation method of the nylon fiber reinforced injectable phenolic moulding plastic. Raw materials for preparing the phenolic moulding plastic mainly include novolac resin, hexamethylenetetramine, an inorganic filler and nylon fiber. The preparation method of the phenolic moulding plastic comprises the following steps: (1) weighing all the raw materials for later use; (2) placing the inorganic filler and a coupling agent into a ball mill or a jar mill for uniformly ball milling, wherein the dosage of the coupling agent is 0.5-10wt% of that of the inorganic filler, and the inorganic filler is one or a combination of two or more of aluminum hydroxide, silica powder, calcite, talc, calcium carbonate, glass beads, kaolin and pottery clay powder; (3) grinding hexamethylenetetramine, and then evenly mixing with the inorganic filler after surface treatment and other raw materials; (4) putting the mixed materials into a twin-screw extruder for extrusion; (5) grinding extrudate after cooling to obtain the nylon fiber reinforced injectable phenolic moulding plastic. The phenolic moulding plastic prepared by the method is higher in mechanical properties and lower in water absorption.

Owner:桂林金格电工电子材料科技有限公司

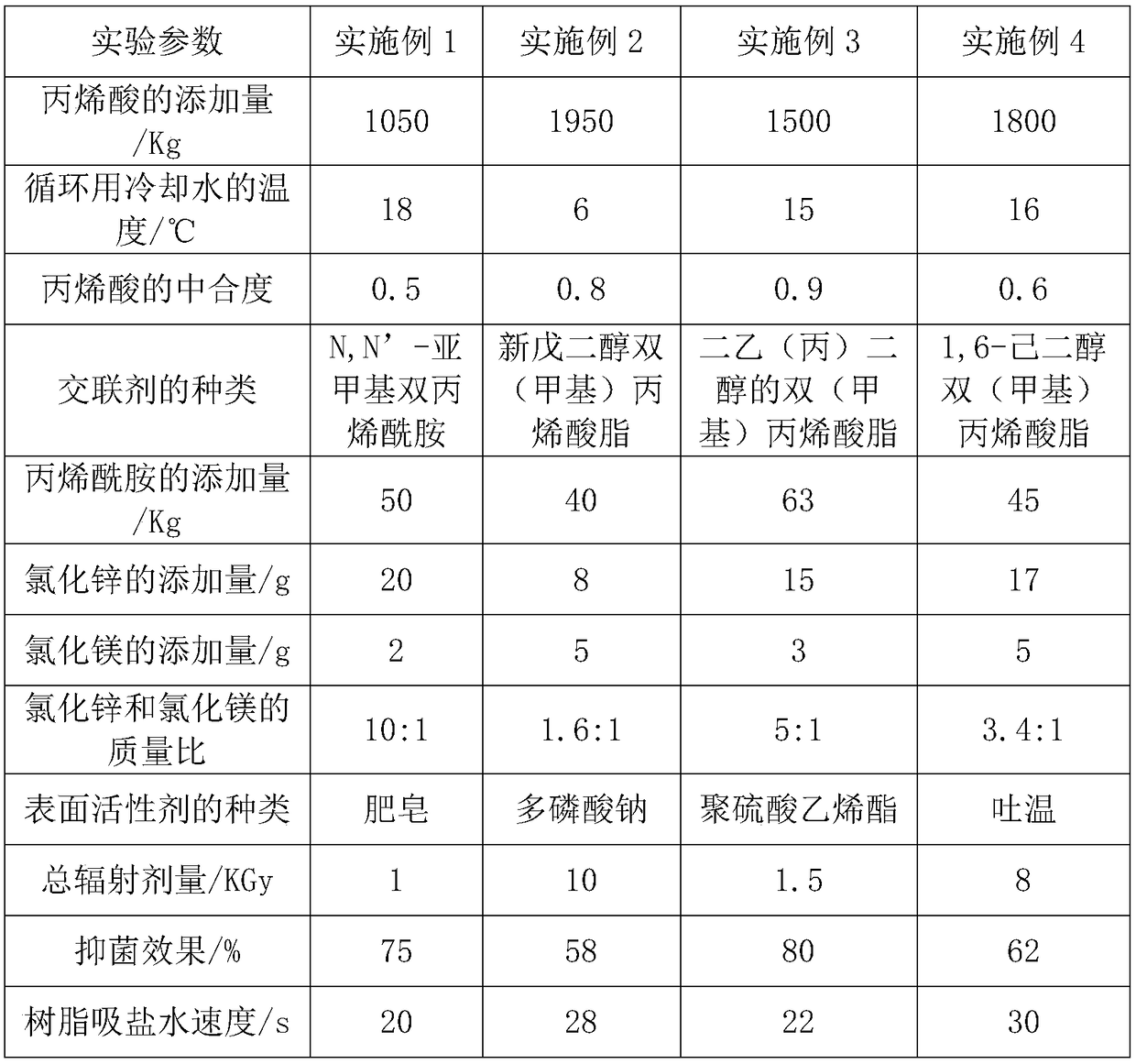

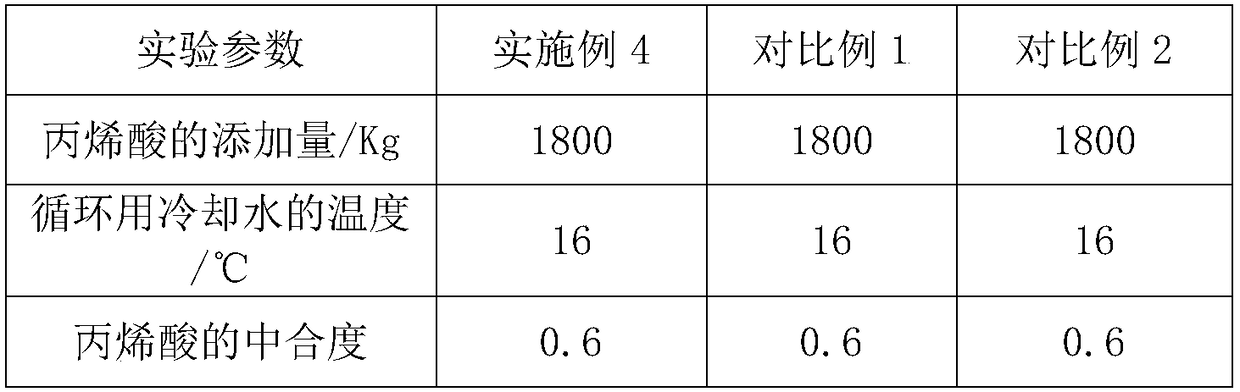

Antibacterial sterilization material produced by irradiation method

InactiveCN108948260AReduce manufacturing costGood antibacterial and sterilizing effectAntibacterial effectRadiochemistry

Owner:肇庆市盛浩新材料科技有限公司

Preparation method of reduced copper slag concrete

The invention discloses a preparation method of reduced copper slag concrete. The preparation method comprises the following steps: calcining and activating copper slag at high temperature; carrying out ultramicro airflow grinding on the copper slag to form copper slag powder; taking the copper slag powder as a raw material for preparing concrete. The elasticity modulus of the concrete is improved, the shrinkage is reduced, the fracture resistance of the concrete is obviously improved, and the durability grade of the concrete is improved.

Owner:中建西部建设新疆有限公司 +1

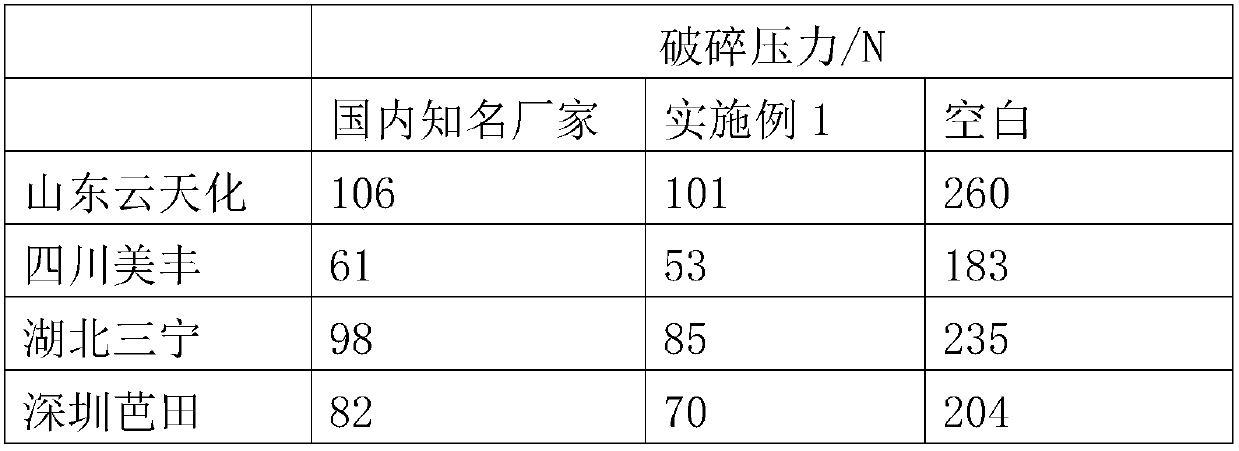

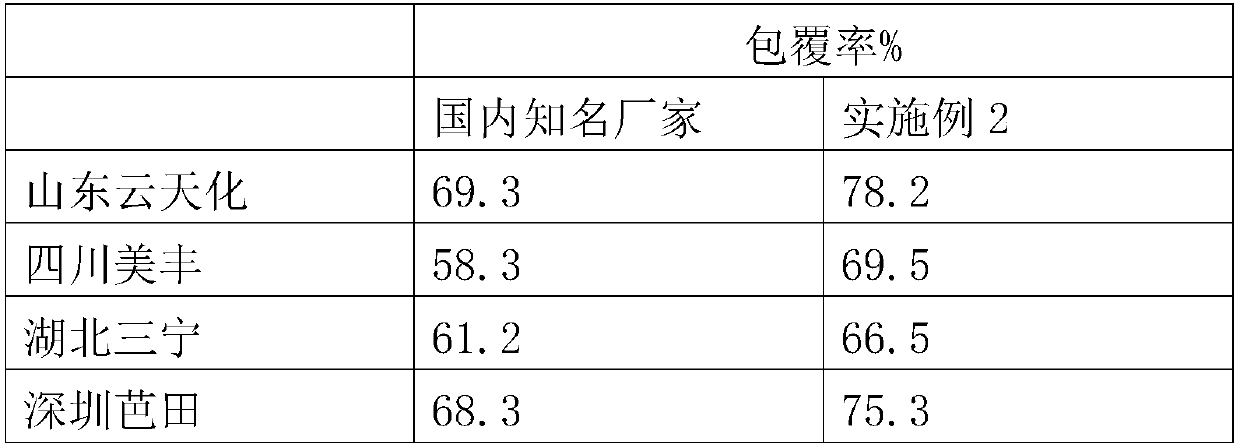

New-type nutritional-type powder anti-blocking agent and application

InactiveCN109665906AGood effectAvoid cakingMagnesium fertilisersAgriculture gas emission reductionTrace elementAdditive ingredient

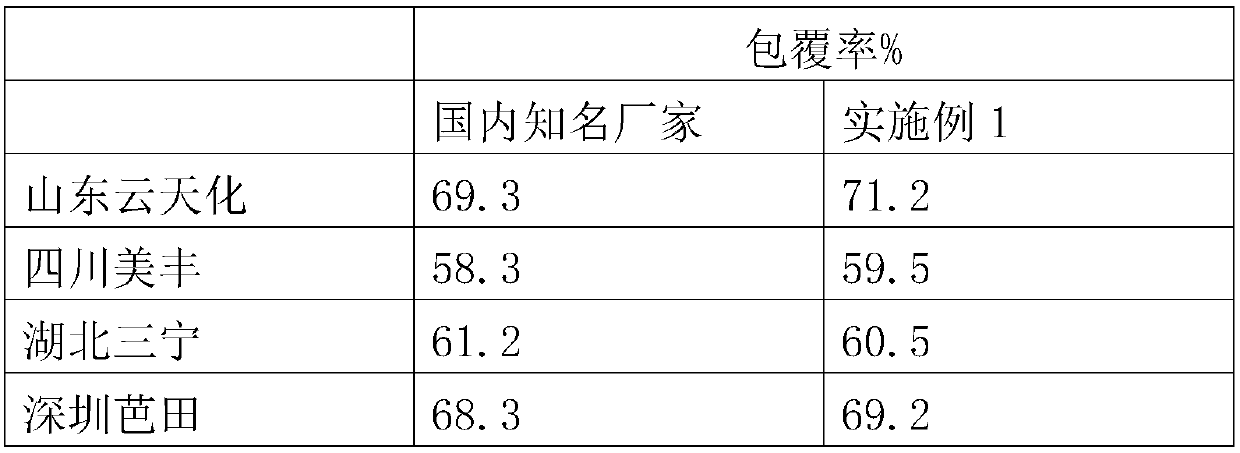

The invention relates to a new-type nutritional-type powder anti-blocking agent and an application. The new-type nutritional-type powder anti-blocking agent is formed by mixing the following substances according to a mass percentage: 20-90% of talcum, 0.1-30% of a medium trace element, 0.1-30% of biological simulin, 0.1-30% of hormone, 0.1-30% of a fertilizer synergist, and 0.1-30% of a biologicalfungicide. Each substance is smashed to be powder of which a particle size is 200-1000 meshes. 1.0-10.0 kg of the new-type nutritional-type powder anti-blocking agent is added per ton of a fertilizerand wrapped, so the fertilizer achieves an anti-blocking purpose. The new-type nutritional-type powder anti-blocking agent is capable of forming a power film layer on the surface of fertilizer particles, reducing mutual adhesion between the particles, and inhibiting salt dissolution-recrystallization between the particles, thereby achieving a purpose of preventing the fertilizer from caking. Thenew-type nutritional-type powder anti-blocking agent is capable of providing nutrient ingredients for crops, enabling a fertilizer utilization ratio to be improved, adding value and increasing effect,and promoting the crops to increase production and increase income.

Owner:HUBEI FORBON TECH

Flammulina velutiper steamed buns and making method thereof

InactiveCN109832553AReduce water absorption rateImprove water absorptionFood scienceSpecific volumeTriticum turgidum

The invention discloses flammulina velutiper steamed buns and a making method thereof. The flammulina velutiper steamed buns comprise the following components in parts by mass of 95-99 parts of wheatflour, 63-66 parts of water, 1 part of high-activity dry yeast and 1-5 parts of flammulina velutiper powder, wherein the total quantity of the flour and the flammulina velutiper powder is 100 parts, and the water addition amount is appropriately increased along with the increase of the addition quantity of the flammulina velutiper powder. The flammulina velutiper steamed buns made by the making method disclosed by the invention are loose, soft and tasteful and high in specific volume; the flammulina velutiper is added, so that the nutrient value of the steamed buns is increased; and except theflammulina velutiper, no other quality modifiers is added, so that the quality and the safety of the steamed buns as staple foods can be well guaranteed.

Owner:HENAN INST OF SCI & TECH

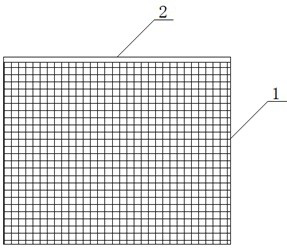

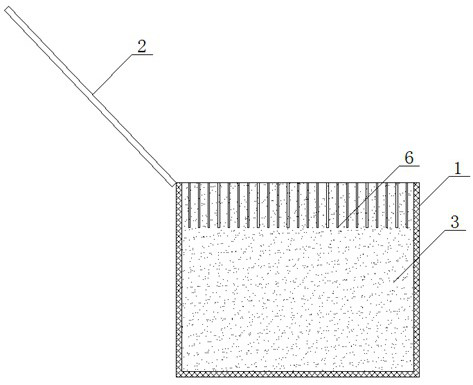

Manufacturing method and using method of ecological restoration plant growing bag for high-cold and high-altitude areas

InactiveCN113973615AWide variety of sourcesLow priceGrowth substratesCulture mediaAgricultural engineeringEngineering

The invention discloses a manufacturing method and a using method of an ecological restoration plant growing bag for a high-cold and high-altitude area. The manufacturing method comprises a filling step and a grass seed implanting step. The using method comprises the steps of digging a field pit, putting the plant growing bag into the pit, and performing field maintenance. The selected materials are wide in source and low in price, the engineering implementation cost can be effectively reduced, and later popularization and application are facilitated; waste soil and stone in the plant growing bag can increase gaps of a cultivation material, it is ensured that the root system of the plant can normally extend, later growth of the plant is guaranteed, and compared with other materials with the same effect, the waste soil and stone are extremely low in price; plant materials selected for manufacturing the plant growing bag can bring good heat preservation and moisture preservation effects to plants in the early stage, the germination rate of the seeds is increased, and nutrients can be provided for plant growth after degradation in the later stage.

Owner:KUNMING UNIV OF SCI & TECH

Polyester fiber reinforced injection phenolic molding compound and its preparation method

Owner:桂林金格电工电子材料科技有限公司

A kind of preparation technology of cefuroxime sodium for injection

The invention provides a preparation process of cefuroxime sodium for injection. The cefuroxime sodium is dissolved in a phosphate buffer solution, activated carbon is used for decolorization, and the filter cake is washed with water to remove impurities in the cefuroxime sodium and prevent cefuroxime During the decolorization process, the sodium fluorescein degrades, and then the crystal seed, resin and acetone are added to the cefuroxime sodium solution for crystal growth, and the water absorption property of the resin is used to absorb the water in the solution during the crystallization process, increasing the proportion of acetone, and then Improve the crystallization effect of cefuroxime sodium, reduce the residual water in the crystal form, improve the stability of cefuroxime sodium for injection, and carry out pressure treatment at regular intervals, which can change the water absorption and absorption of the resin when the crystallization reaches the bottleneck. The solubility of cefuroxime sodium promotes the precipitation of cefuroxime sodium crystals.

Owner:HAINAN HAILING CHEMIPHARMA CORP

Hemp fiber reinforced injection phenolic molding compound and its preparation method

ActiveCN103937150BGood dispersionImprove mechanical propertiesPlastic injection moldingHexamethylenetetramine

The invention discloses a fibrilia-reinforced injection-type phenol aldehyde molding compound and a preparation method thereof. The phenol aldehyde molding compound is mainly prepared from linear phenol aldehyde resin, hexamethylenetetramine, inorganic filler and fibrilia. The preparation method comprises the following steps: 1) weighing the raw materials for later use; 2) putting the inorganic filler and coupling agent in a ball mill or ball milling tank, and carrying out uniform ball milling, wherein the coupling agent accounts for 0.5-10 wt% of the inorganic filler, and the inorganic filler is one or combination of more than two of aluminum hydroxide, silicon micropowder, calcite, talcum, calcium carbonate, glass microballoon, kaolin and figuline powder; 3) pulverizing the hexamethylenetetramine, and uniformly mixing with the surface-treated inorganic filler and the other raw materials; 4) adding the mixture into a double screw extruder, and extruding; and 5) cooling the extruded stock, and pulverizing. The phenol aldehyde molding compound prepared by the method has the advantages of higher mechanical properties and lower water absorptivity.

Owner:桂林金格电工电子材料科技有限公司

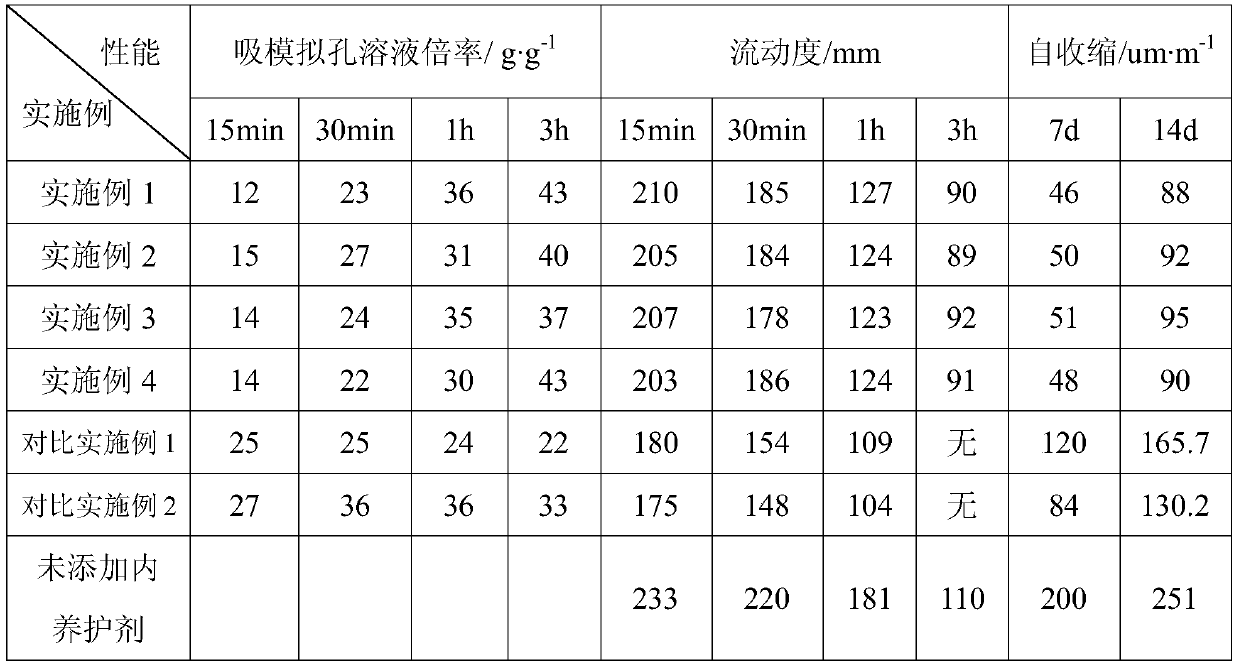

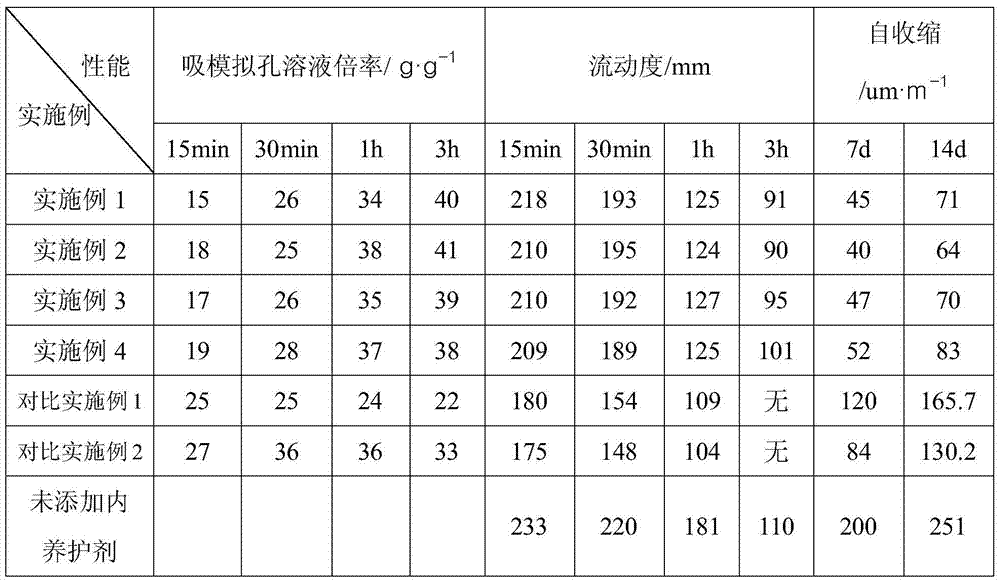

A kind of preparation method of silane modified concrete internal curing agent

ActiveCN105330334BReduced performance impactReduce water absorption rateChemical structureCross-link

The invention provides a preparation method of a silane modified concrete internal curing agent. The preparation method comprises steps as follows: inorganic clay is completely dispersed in deionized water, a neutralized acrylic acid solution, a cross-linking agent and an initiator are added and uniformly mixed, the mixture is heated to 40-60 DEG C and reacts for 8-12 h, superabsorbent resin gel is obtained and subjected to granulation, drying, crushing, screening and surface crosslinking, and superabsorbent resin is obtained; a silane coupling agent is dissolved in ethanol, the superabsorbent resin is added to be sufficiently mixed, the mixture is put in an oven at the temperature of 100-140 DEG C and reacts for 1-2 h, and the final concrete internal curing agent is obtained. According to the method, a preparation process is simple and convenient, a chemical structure is easy to control, the prepared internal curing agent has a lower water absorption rate, influence of the internal curing agent on workability of concrete can be reduced, the early self-constriction and reduction effect of the concrete is improved, and the problem of early cracking of the concrete is solved.

Owner:JIANGSU SOBUTE NEW MATERIALS

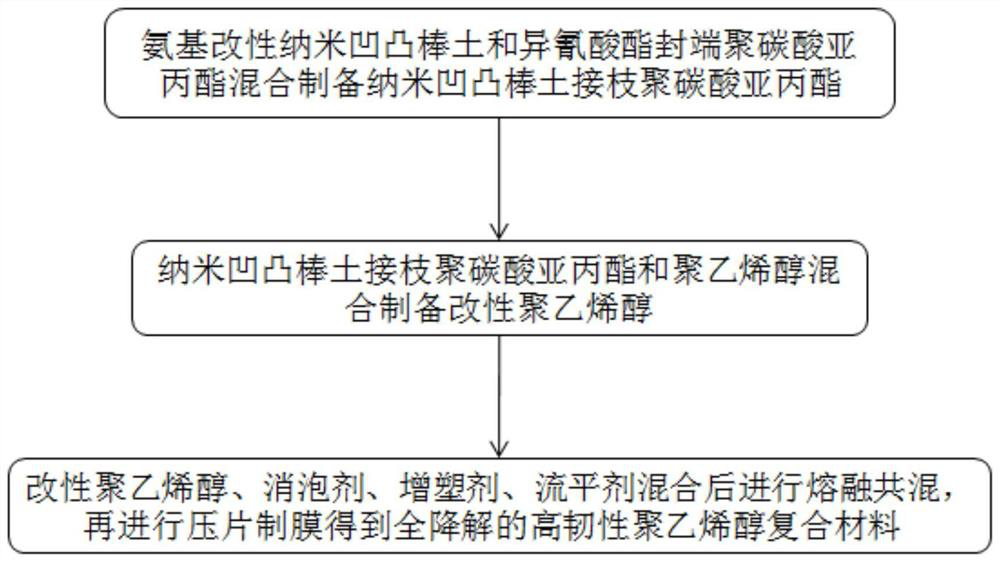

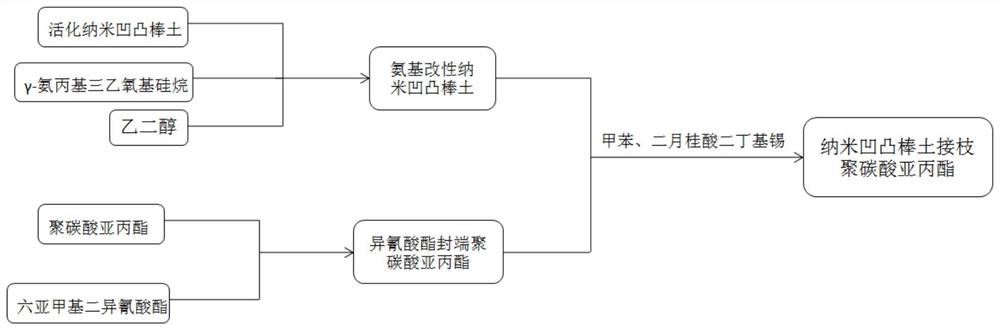

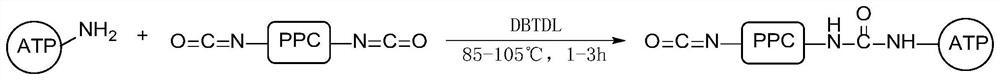

Fully-degradable high-toughness polyvinyl alcohol composite material and preparation method thereof

The invention relates to the technical field of fully-degradable materials, and discloses a preparation method of a fully-degradable high-toughness polyvinyl alcohol composite material, which comprises the following steps: carrying out melt blending on modified polyvinyl alcohol, a defoaming agent, a plasticizer and a flatting agent, and tabletting in a press vulcanizer to prepare a film, thereby obtaining the fully-degradable high-toughness polyvinyl alcohol composite material. The modified polyvinyl alcohol is prepared from nano attapulgite grafted polypropylene carbonate and polyvinyl alcohol through a reaction, nano attapulgite, polypropylene carbonate and polyvinyl alcohol all have excellent degradation performance, polyvinyl alcohol is modified through nano attapulgite grafted polypropylene carbonate, the hydrophilic performance of polyvinyl alcohol can be reduced, and the degradation performance of polyvinyl alcohol is improved. Meanwhile, the mechanical property and the thermal stability of polyvinyl alcohol are improved, and the polyvinyl alcohol composite material has the advantages of high toughness, full degradation and good thermal stability.

Owner:悟锐新材料科技(江苏)有限公司

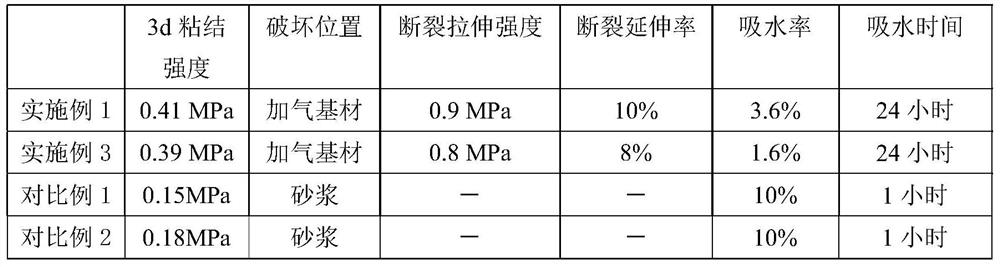

A kind of board seam extrusion material for ALC exterior wall board and preparation method thereof

The invention relates to a slab joint shoving material for an ALC external wallboard and a preparation method thereof. The slab joint shoving material is prepared from, by weight, 30-97% of a cementing agent, 1-10 parts of a self-repairing master batch, 1-5 parts of a volume stabilizer, 0-1 part of a defoaming agent, 0-60 parts of filler, 1-10 parts of emulsified paraffin, 0.1-2 parts of a water retaining agent, 0.1-1 part of a thixotropic agent and 0-1 part of a condensing time regulating agent. The slab joint shoving material has the good bonding strength, tensile breaking strength and breaking elongation at break and has the low volume change rate, water absorbing rate and water absorbing speed; meanwhile, the slab joint shoving material further has the certain micro-crack self-repairing, sealing performance and flexibility, and ensures the engineering quality of an autoclaved aerated concrete external wallboard.

Owner:BEIJING BBMG AUTOCLAVED AERATED CONCRETE

Nylon fiber reinforced injection phenolic molding compound and its preparation method

Owner:桂林金格电工电子材料科技有限公司

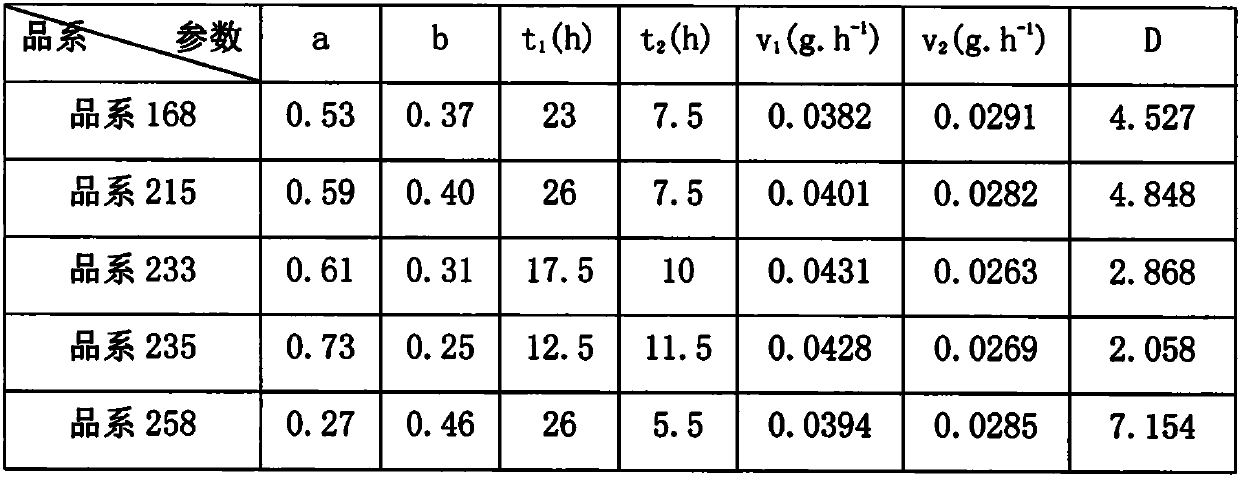

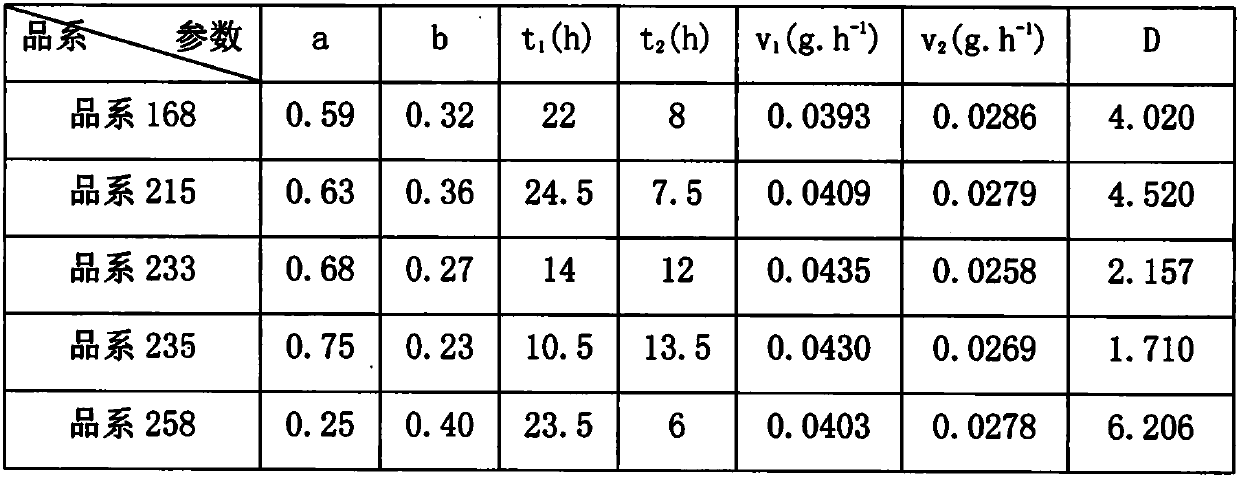

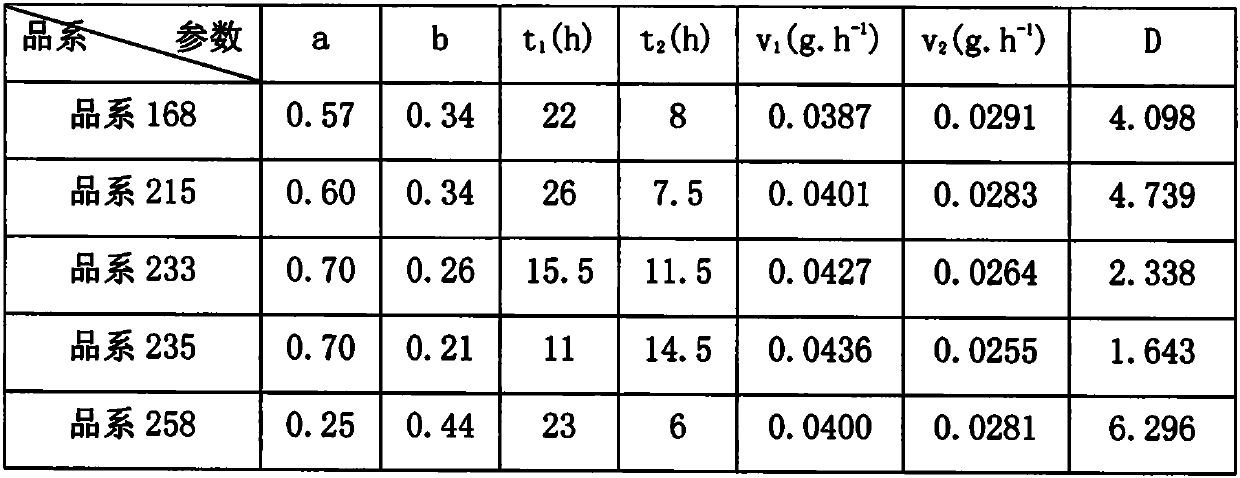

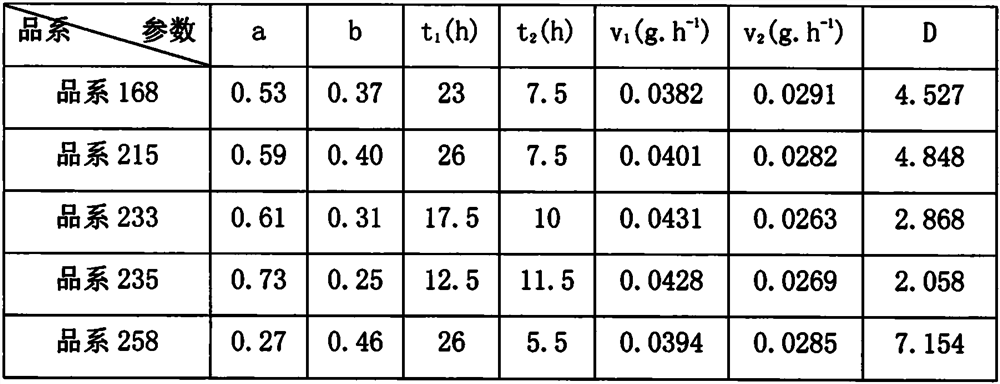

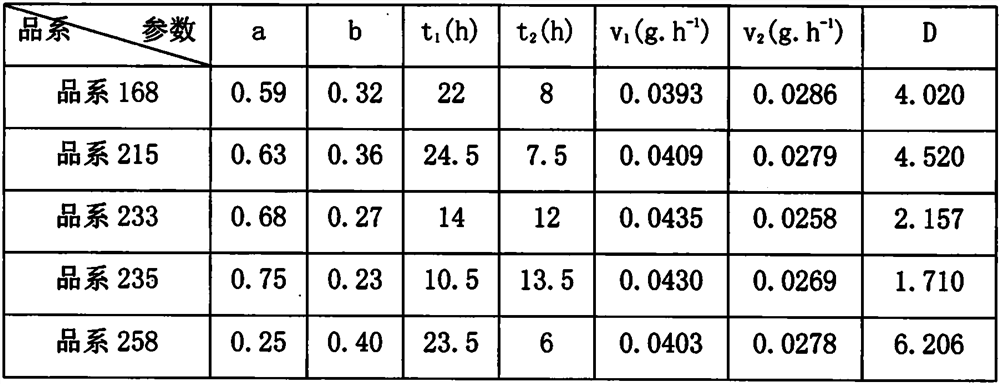

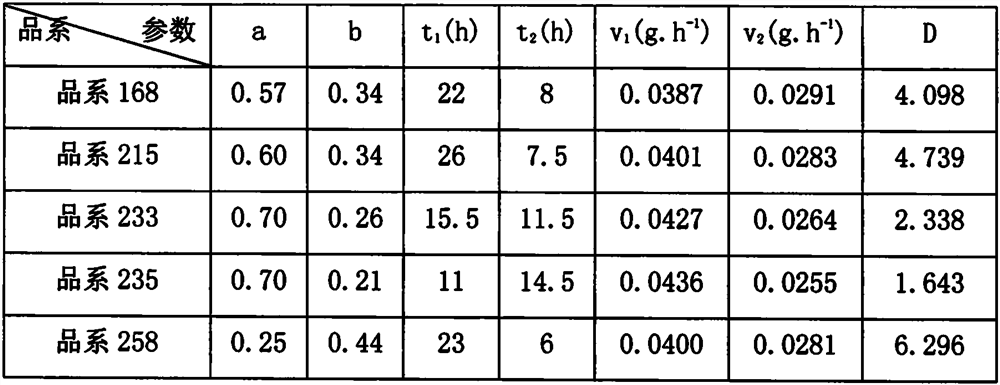

Screening method for ear sprouting-resistant wheat varieties (lines)

ActiveCN111436245AHigh D valueComprehensive ear germination resistanceResourcesTesting plants/treesSproutingAgronomy

The present invention provides a screening method for ear sprouting-resistant wheat varieties (lines) by utilizing a protective mechanism of seeking advantages and avoiding disadvantages for wheat, and belongs to the technical field of wheat breeding. The method comprises the following steps of in a variety (line) identification nursery, randomly selecting wheat ears of the varieties (lines) 35 days, 38 days and 40 days after flowering of the wheat; sequentially measuring the wheat ear water carrying rates, the grain bubbling water demand rates, the grain imbibition time, the water-soaked wheat ear dewatering time, the grain water absorption rates and the grain dewatering rates of the varieties (lines) in different days; calculating the comprehensive ear sprouting-resistant values of the varieties in different days and performing value permutation; and selecting the minimum ear sprouting-resistant values of the varieties (lines) for evaluation, thereby performing identification and evaluation on the ear sprouting resistance of the wheat varieties (lines). Indexes of reducing the ear sprouting harm are brought into evaluation standards of the ear sprouting resistance of the wheat varieties (lines), so that the screened ear sprouting-resistant wheat varieties (lines) are close to agricultural production.

Owner:邯郸市农业科学院

A kind of preparation method of silane modified concrete internal curing agent

ActiveCN105330783BReduced performance impactReduce water absorption rateCross-linkChemical structure

The invention provides a preparation method of a silane modified concrete internal curing agent. The preparation method comprises steps as follows: polyvinyl alcohol is completely dissolved in deionized water, a neutralized acrylic acid solution, a cross-linking agent and an initiator are added and uniformly mixed, the mixture is heated to 40-60 DEG C and reacts for 8-12 h, superabsorbent resin gel is obtained and subjected to granulation, drying, crushing, screening and surface crosslinking, and superabsorbent resin is obtained; a silane coupling agent is dissolved in benzene, the superabsorbent resin is added to be sufficiently mixed, the mixture is put in an oven at the temperature of 120-160 DEG C and reacts for 1-2 h, and the final concrete internal curing agent is obtained. According to the method, a preparation process is simple and convenient, a chemical structure is easy to control, the prepared internal curing agent has a lower water absorption rate, influence of the internal curing agent on workability of concrete can be reduced, the early self-constriction and reduction effect of the concrete is improved, and the problem of early cracking of the concrete is solved.

Owner:JIANGSU SOBUTE NEW MATERIALS

A screening method for spike-tolerant sprouting wheat varieties (lines)

ActiveCN111436245BShorten the time of water stressIncreased sparging water demandResourcesTesting plants/treesSproutingAgronomy

The invention utilizes the protection mechanism of wheat "seeking advantages and avoiding disadvantages" to provide a screening method for ear-resistant germination wheat varieties (strains), which belongs to the technical field of wheat breeding and comprises the following steps: in the variety (strain) identification nursery, respectively 35, 38 and 40 days after wheat flowering, the wheat ears of each variety (line) were randomly selected; the water loading rate of wheat ears, grain bubbling water demand rate, and grain imbibition stage required for each variety (line) were measured in sequence. Time, dehydration time of soaked wheat ears, grain water absorption rate and grain dehydration rate; calculate the comprehensive ear germination value of each variety in different days and arrange them in size; select the minimum ear germination value of each variety (line) to evaluate, so as to evaluate the wheat The ear germination resistance of varieties (lines) was identified and evaluated. In the present invention, the indicators for mitigating the harm of ear germination are incorporated into the evaluation criteria of ear germination tolerance of wheat varieties (strains), and then the selected wheat varieties (strains) of ear germination tolerance are close to agricultural production.

Owner:邯郸市农业科学院

Biologic polyamide quadripolymer and synthesis method thereof

ActiveCN103030803BGood environmental stabilityReduce the degradation ratePolymer scienceSynthesis methods

Owner:BEIJING UNIV OF CHEM TECH

A kind of high rigidity and low water absorption nylon 6 composite material

ActiveCN109666291BImprove barrier propertiesHigh heat distortion temperatureSilanesPolytetrafluoroethylene

Owner:厦门德丰行塑胶工业有限公司

Preparation method of cotton fiber reinforced injection phenolic molding compound

The invention discloses a preparation method of a cotton-fiber-reinforced injection-type phenol aldehyde molding compound. The phenol aldehyde molding compound is mainly prepared from linear phenol aldehyde resin, hexamethylenetetramine, inorganic filler and cotton fiber. The preparation method comprises the following steps: 1) weighing the raw materials for later use; 2) putting the inorganic filler and coupling agent in a ball mill or ball milling tank, and carrying out uniform ball milling, wherein the coupling agent accounts for 0.5-10 wt% of the inorganic filler, and the inorganic filler is one or combination of more than two of aluminum hydroxide, silicon micropowder, calcite, talcum, calcium carbonate, glass microballoon, kaolin and ceramic powder; 3) pulverizing the hexamethylenetetramine, and uniformly mixing with the surface-treated inorganic filler and the other raw materials; 4) adding the mixture into a double screw extruder, and extruding; and 5) cooling the extruded stock, and pulverizing. The phenol aldehyde molding compound prepared by the method has the advantages of higher mechanical properties and lower water absorptivity.

Owner:桂林金格电工电子材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com