Fully-degradable high-toughness polyvinyl alcohol composite material and preparation method thereof

A technology of polyvinyl alcohol and composite materials, applied in the field of fully degradable materials, can solve the problems of poor water resistance and difficult processing of polyvinyl alcohol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

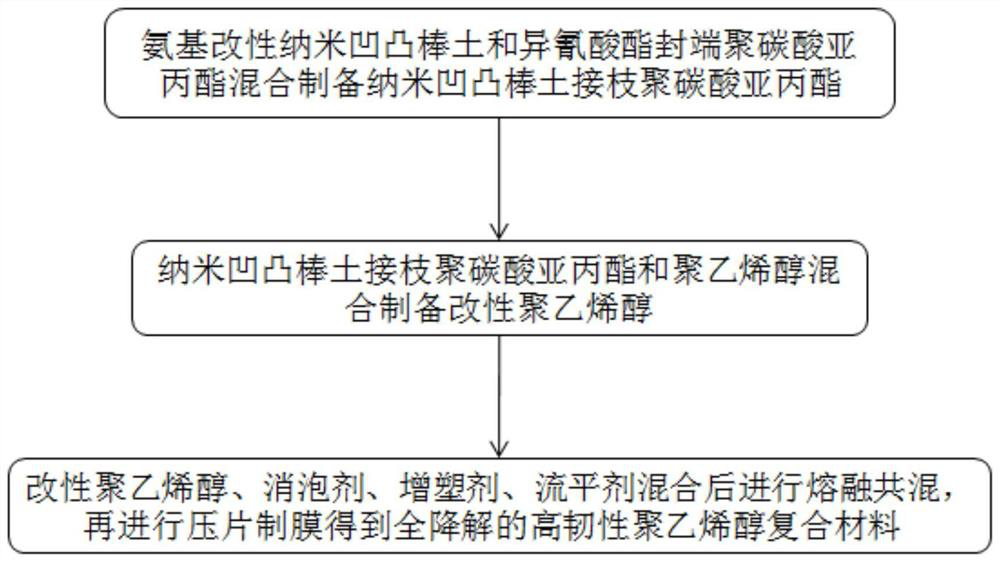

Method used

Image

Examples

Embodiment 1

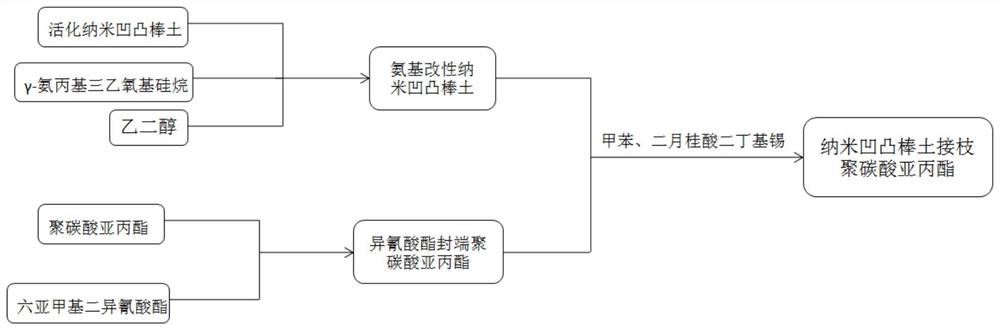

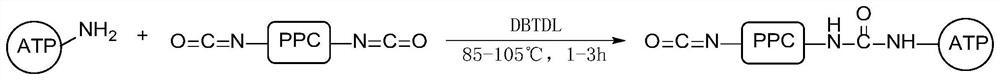

[0035] A preparation method of modified polyvinyl alcohol, comprising the following steps:

[0036](1) be that 100:1200 nanometer attapulgite, hydrochloric acid solution are stirred and mixed by mass ratio, wherein hydrochloric acid solution is the hydrochloric acid aqueous solution of 1mol / L, heating and reacting in the stirring process, the temperature of reaction is 55 ℃, and the time of reaction is 4h, after the reaction is completed, suction filtration, use deionized water to wash to neutrality, after the washing is completed, vacuum dry, the temperature of vacuum drying is 60 ° C, and the time of vacuum drying is 6h, after drying, the activated nano attapulgite is obtained; The mass ratio of 2400:20:11 of ethylene glycol, activated nano attapulgite, and γ-aminopropyltriethoxysilane was ultrasonically dispersed, and a reaction occurred during the dispersion process. The reaction temperature was 105 °C, and the reaction time was 5h, after the reaction is completed, suction...

Embodiment 2

[0041] A preparation method of modified polyvinyl alcohol, comprising the following steps:

[0042] (1) be that the nanometer attapulgite soil and hydrochloric acid solution of 100:1800 are mixed by mass ratio, wherein the hydrochloric acid solution is the hydrochloric acid aqueous solution of 1mol / L, in the stirring process, heating is reacted, and the temperature of reaction is 60 ℃, and the time of reaction is 6h, after the reaction is completed, suction filtration, use deionized water to wash to neutrality, after the washing is completed, vacuum dry, the temperature of vacuum drying is 60 ℃, the time of vacuum drying is 6h, after drying, the activated nano attapulgite is obtained; The mass ratio of 3000:20:16 of ethylene glycol, activated nano attapulgite, and γ-aminopropyltriethoxysilane was ultrasonically dispersed, and a reaction occurred during the dispersion process. The reaction temperature was 120 °C, and the reaction time was 6h, after the reaction is completed, su...

Embodiment 3

[0047] A preparation method of modified polyvinyl alcohol, comprising the following steps:

[0048] (1) be that 100:2500 nanometer attapulgite, hydrochloric acid solution are mixed by mass ratio, wherein the hydrochloric acid solution is the hydrochloric acid aqueous solution of 1mol / L, heating and reacting in the stirring process, the temperature of reaction is 65 ℃, and the time of reaction is 8h, after the reaction is completed, suction filtration, use deionized water to wash to neutrality, after the washing is completed, vacuum dry, the temperature of vacuum drying is 60 ℃, the time of vacuum drying is 6h, after drying, the activated nano attapulgite is obtained; The mass ratio of 3600:20:21 of ethylene glycol, activated nano attapulgite, and γ-aminopropyltriethoxysilane was ultrasonically dispersed, and a reaction occurred during the dispersion process. The reaction temperature was 135 ° C, and the reaction time was 8h, after the reaction is completed, suction filtration,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com