Polyester fiber reinforced injection phenolic molding compound and its preparation method

A technology of phenolic molding compound and polyester fiber, which is applied in the field of phenolic molding compound, can solve the problems of insufficient mechanical properties, high thermal deformation temperature of molding compound, and low thermal weight loss rate at high temperature, so as to improve interfacial compatibility and improve Dispersibility and the effect of reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

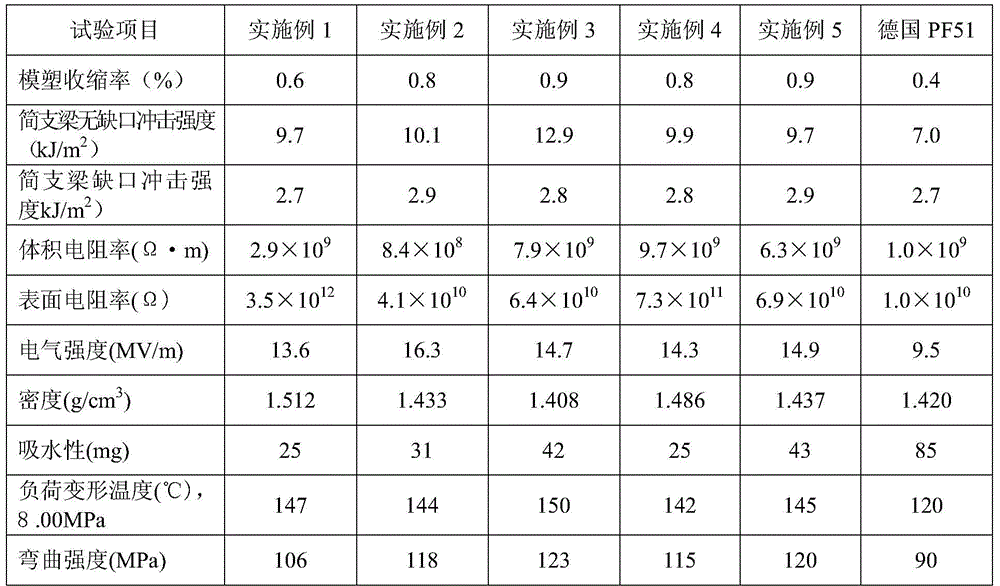

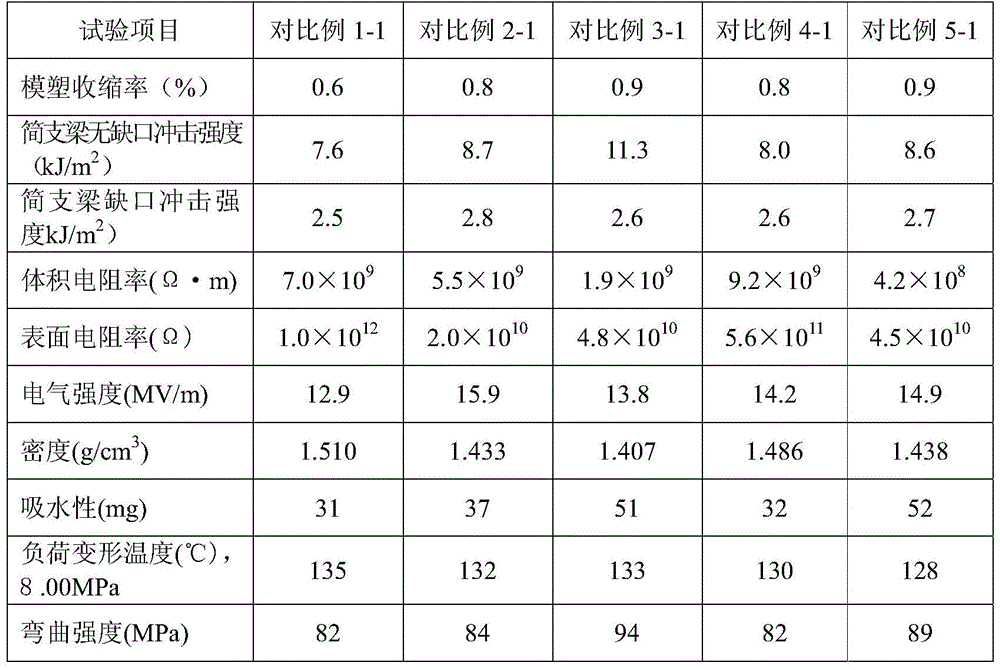

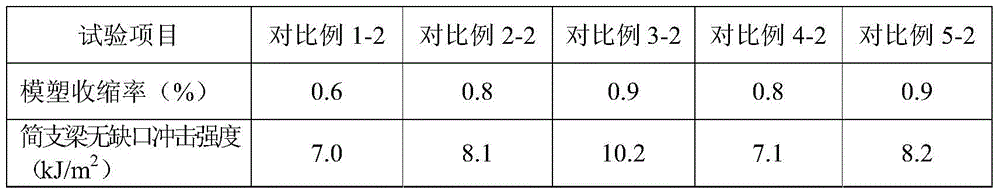

Examples

Embodiment 1

[0045] 1) Weigh the following components for later use: 100 parts of novolac resin (that is, thermoplastic phenolic resin, the same below), 10 parts of hexamethylenetetramine, 80 parts of silicon micropowder of 400-600 mesh, and 2-5 mm in length 25 parts of polyester fiber, 3 parts of magnesium hydroxide, 1 part of calcium stearate;

[0046] 2) Take silicon micropowder and titanate coupling agent equivalent to 0.5% of its dosage and place it in a ball mill tank for ball milling, control the speed of the ball mill tank to 10rpm, and the ball milling time is 10min;

[0047] 3) Take hexamethylenetetramine and pulverize it to 80 meshes, and then mix it evenly with the surface-treated silicon micropowder and other components;

[0048] 4) put the mixed material into a twin-screw extruder for extrusion, the barrel temperature of the twin-screw extruder is 75-90°C, and the screw rotation speed is 80rpm;

[0049] 5) After the extruded material is cooled to normal temperature, it is pu...

Embodiment 2

[0062] 1) Weigh the following components for later use: 100 parts of novolac resin, 15 parts of hexamethylenetetramine, 50 parts of calcite of 600-800 mesh, 45 parts of polyester fiber with a length of 1-10 mm, 5 parts of magnesium hydroxide 2 parts, 2 parts of zinc stearate, 5 parts of iron red;

[0063] 2) Take calcite and aluminate coupling agent equivalent to 4% of its dosage and place it in a ball mill jar for ball milling, control the rotating speed of the ball mill jar to 50rpm, and the ball milling time is 80min;

[0064] 3) get hexamethylenetetramine and pulverize to 100 orders, then mix with surface-treated calcite and other components;

[0065] 4) put the mixed material into a twin-screw extruder for extrusion, the barrel temperature of the twin-screw extruder is 90-100°C, and the screw rotation speed is 90rpm;

[0066] 5) After the extruded material is cooled to normal temperature, it is pulverized into irregular powder with a diameter of 2-5 mm to obtain the poly...

Embodiment 3

[0079] 1) Take the following components by weight percentage for later use: 100 parts of novolac resin, 20 parts of hexamethylenetetramine, 30 parts of calcium carbonate of 100-300 mesh, 55 parts of polyester fiber with a length of 5-10 mm, 1 part of calcium oxide, 5 parts of zinc stearate;

[0080] 2) Take calcium carbonate and a silane coupling agent equivalent to 6% of its dosage and place it in a ball mill jar for ball milling, control the speed of the ball mill jar to 30rpm, and the ball milling time is 60min;

[0081] 3) take hexamethylenetetramine and pulverize it to 80 meshes, then mix it evenly with surface-treated calcium carbonate and other components;

[0082] 4) put the mixed material into a twin-screw extruder for extrusion, the barrel temperature of the twin-screw extruder is 75-85°C, and the screw rotation speed is 90rpm;

[0083] 5) After the extruded material is cooled to normal temperature, it is pulverized into irregular powder with a diameter of 4-6 mm to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com