A kind of board seam extrusion material for ALC exterior wall board and preparation method thereof

A technology for exterior wall panels and panel seams, which is applied in the field of structural sealing materials, can solve problems such as failure of sealing and waterproof functions, complex maintenance, and meet requirements at the same time, so as to improve sealing performance and flexibility, low volume change rate, and ensure engineering quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

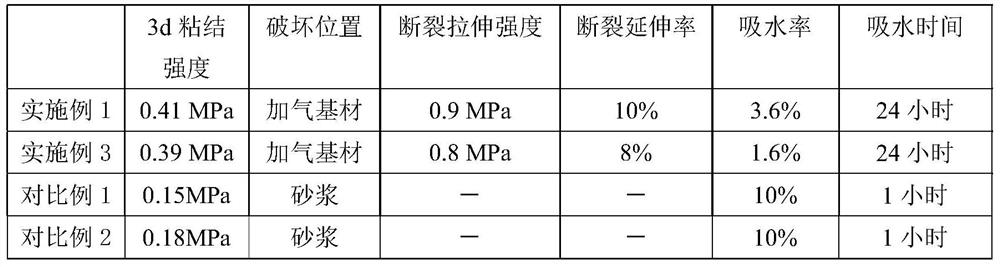

Examples

Embodiment 1

[0042] Embodiment 1 A kind of board seam extrusion material

[0043] The formula of the board seam extrusion material is as follows:

[0044] In parts by weight, 80 parts of α-type high-strength gypsum, 3 parts of 52.5# sulfoaluminate cement, 3 parts of carbon nanotubes, 10 parts of pure acrylic emulsion, 6 parts of self-repairing masterbatch (I), 2 parts of anhydrite, P803 0.1 part, 15 parts of heavy calcium powder, 8 parts of emulsified paraffin, 0.1 part of low viscosity HPMC, 0.1 part of lignocellulose, and 0.03 part of citric acid.

Embodiment 2 Embodiment 1

[0045] Embodiment 2 The preparation method of the slotted pulping material described in Embodiment 1

[0046] Concrete preparation steps include:

[0047]Before using the resin emulsion, fully mix 1-3 parts of cement or α-type high-strength gypsum powder with the emulsion. When using the self-healing masterbatch, the self-healing masterbatch and emulsified paraffin should be fully mixed and stirred in advance. In a certain amount of water, add each powder according to the above formula, and stir for 3 minutes. Then add the pre-mixed resin emulsion and self-healing masterbatch, and the ratio of water to material is 0.25-0.30.

Embodiment 3

[0048] Embodiment 3 A kind of board seam extrusion material

[0049] The formula of the board seam extrusion material is as follows:

[0050] In parts by weight, 40 parts of 52.5 sulfoaluminate cement, 2 parts of α-type high-strength gypsum, 6 parts of carbon nanotubes, 15 parts of pure acrylic emulsion, 4 parts of self-repairing masterbatch (II), 4 parts of anhydrite, P803 0.1 36 parts of quartz sand, 6 parts of emulsified paraffin, 0.1 part of low viscosity HPMC, 0.1 part of lignocellulose, 0.03 part of tartaric acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com