High-rigidity low-water-absorption nylon 6 composite material

A composite material, low water absorption technology, applied in the field of nylon modification, can solve the problems of affecting the dimensional stability of the product, the existence of defects in mechanical strength, and the decrease of material rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

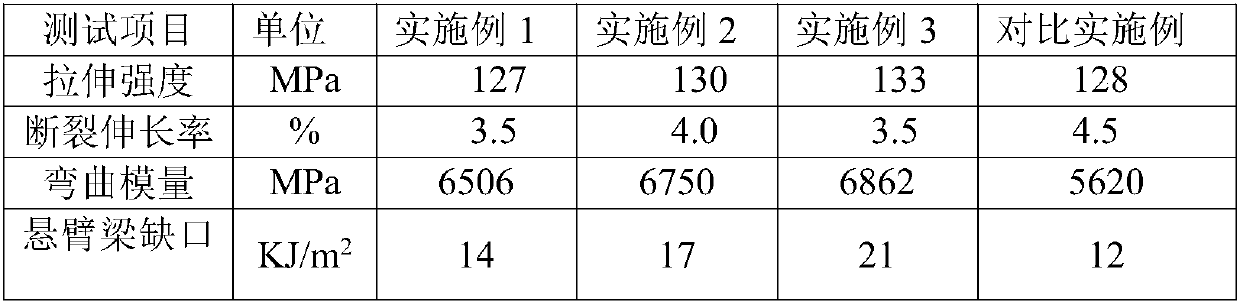

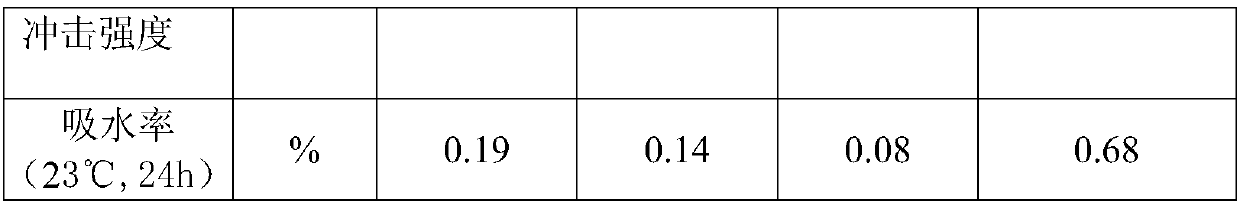

Examples

Embodiment 1

[0018] A kind of nylon 6 composite material with high rigidity and low water absorption, comprising the following raw materials in parts by weight: 6100 parts of nylon, 10 parts of polym-xylylenediamine adipamide, 3 parts of nano-montmorillonite, 30 parts of alkali-free glass fiber, silane diacetate 1 part of joint agent solution, 3 parts of nano-layered silicate, 5 parts of acrylonitrile-butadiene-styrene-terpolymer, 1 part of polytetrafluoroethylene (PTFE), maleic anhydride grafted ethylene-octyl 3 parts of vinyl copolymer, 1 part of compatibilizer, 0.1 part of tris(2,4-di-tert-butylphenyl) phosphite, 0.1 part of silicone masterbatch, 0.1 part of H10.

[0019] The silane coupling agent solution is a solution prepared by γ-aminopropyltriethoxysilane and methanol or ethanol with a mass ratio of 1:3;

[0020] The compatibilizer is a vinyl elastomer bifunctionalized with maleic anhydride and acrylate.

[0021] The glass fibers are chopped glass fibers with a single filament dia...

Embodiment 2

[0029] A kind of nylon 6 composite material with high rigidity and low water absorption, comprising the following raw materials in parts by weight: nylon 6110 parts, polym-xylylenediamine adipamide 20 parts, nano-montmorillonite 4 parts, alkali-free glass fiber 40 parts, silane di 1.5 parts of joint agent solution, 4 parts of nano-layered silicate, 8 parts of acrylonitrile-butadiene-styrene-terpolymer, 5 parts of polytetrafluoroethylene (PTFE), maleic anhydride grafted ethylene-octyl 4 parts of vinyl copolymer, 3 parts of compatibilizer, 0.5 parts of tris(2,4-di-tert-butylphenyl) phosphite, 0.5 parts of silicone masterbatch, and 0.5 parts of H20.

[0030] The silane coupling agent solution is a solution prepared by γ-aminopropyltriethoxysilane and methanol or ethanol with a mass ratio of 1:3.

[0031] The compatibilizer is a vinyl elastomer bifunctionalized with maleic anhydride and acrylate.

[0032] The alkali-free glass fibers are chopped glass fibers with a single filamen...

Embodiment 3

[0036] A kind of nylon 6 composite material with high rigidity and low water absorption, comprising the following raw materials in parts by weight: 120 parts of nylon, 30 parts of polym-xylylenediamine adipamide, 5 parts of nanometer montmorillonite, 50 parts of alkali-free glass fiber, silane diacetate 2 parts of joint agent solution, 5 parts of nano-layered silicate, 10 parts of acrylonitrile-butadiene-styrene-terpolymer, 10 parts of polytetrafluoroethylene (PTFE), maleic anhydride grafted ethylene-octyl 5 parts of vinyl copolymer, 5 parts of compatibilizer, 1 part of tris(2,4-di-tert-butylphenyl) phosphite, 1 part of silicone masterbatch, 1 part of HS-03.

[0037] The silane coupling agent solution is a solution prepared by γ-aminopropyltriethoxysilane and methanol or ethanol with a mass ratio of 1:3;

[0038] The compatibilizer is a vinyl elastomer bifunctionalized with maleic anhydride and acrylate.

[0039] The glass fibers are chopped glass fibers with a single filamen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com