Low-hygroscopicity epoxy resin and preparation method thereof

A technology of epoxy resin and low hygroscopicity, applied in the field of low hygroscopicity epoxy resin and its preparation, can solve the problem that epoxy resin crosslinking density, mechanical properties and heat resistance are not improved at the same time, and the performance of matrix resin is degraded , easy to migrate to the surface and other problems, to achieve good nano-enhancing effect, improve heat resistance and barrier properties, and improve the effect of barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

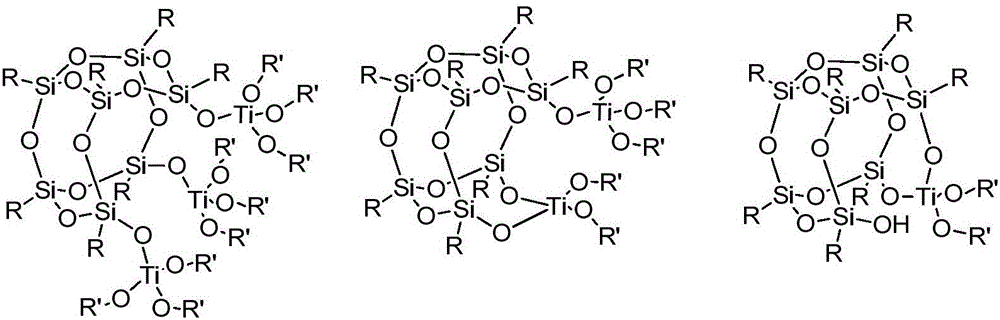

[0028] (1) Synthesis of organic titanium hybrid silsesquioxane

[0029] Dissolve 4g of heptaisobutylsilsesquioxane trisilanol in 100mL of chloroform, stir for 20min under nitrogen flow, then add 1.73mL of n-butyl titanate (molar ratio, heptaisobutylsilsesquioxane Trisilanol: n-butyl titanate = 1:1), stirred for 20 minutes and then heated to 60°C for reflux reaction for 4 hours. After the reaction was completed, the solution was concentrated by rotary evaporation, and finally organic titanium hybrid silsesquioxane was precipitated with acetonitrile .

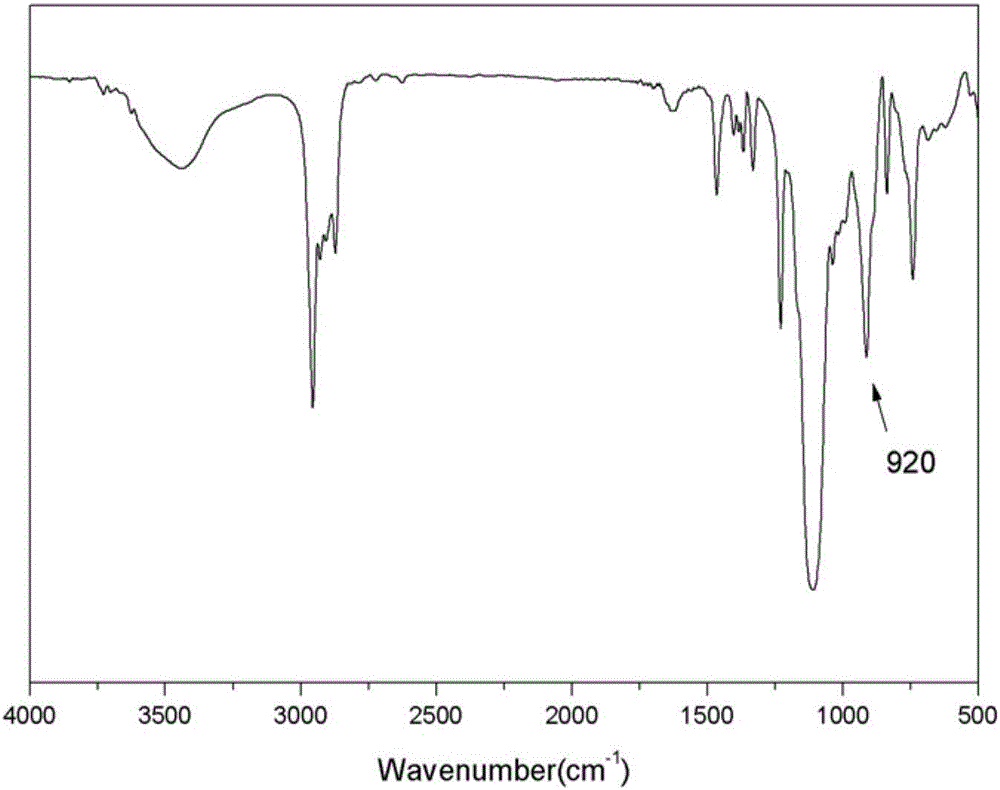

[0030] The infrared spectrogram characterization of the organic titanium hybrid silsesquioxane is shown in figure 1 shown. 920cm -1 The spectral peak is the characteristic absorption peak of -Si-O-Ti- group.

[0031] (2) Preparation of low hygroscopicity epoxy resin

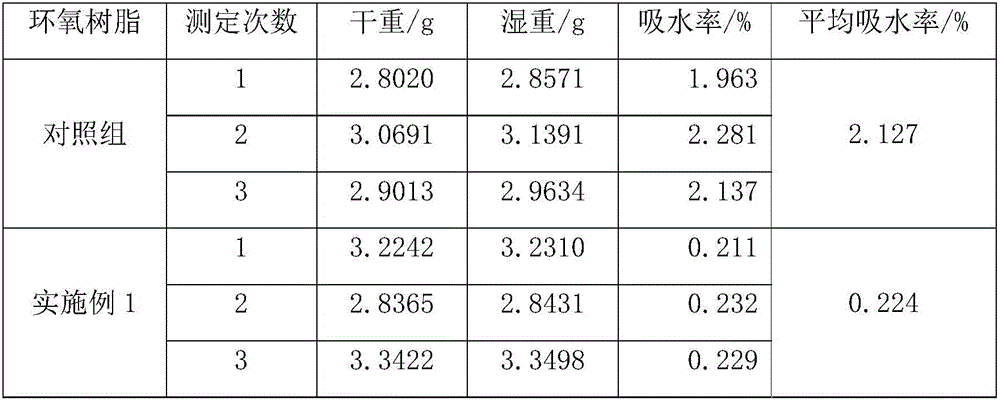

[0032] Weigh 20g of epoxy resin E-51, heat up to 100°C, add 1g of organic titanium hybrid silsesquioxane (according to mass percentage, organic titanium hybrid...

Embodiment 2~3

[0041] With embodiment 1 process, change the addition amount of organic titanium hybrid silsesquioxane in step (2), be respectively 2.0g and 3.0g (by mass percentage, organic titanium hybrid silsesquioxane is respectively epoxy 10%, 15% of the resin). Measure the water absorption according to the method described in step (4). The measurement results are shown in Table 2.

[0042] Table 2

[0043] Example

Embodiment 4~6

[0045] The same process as in Example 1, changing the feeding amount of n-butyl titanate in step (1) to 3.46 mL (molar ratio, heptaisobutylsilsesquioxane trisilanol: n-butyl titanate=1:2) , change the amount of organic titanium hybrid silsesquioxane added in step (2), respectively 1.0g, 2.0g, 3.0g (by mass percentage, organic titanium hybrid silsesquioxane is 5% of epoxy resin respectively %, 10%, 15%). Measure the water absorption according to the method described in step (4). The measurement results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com