Preparation method of reduced copper slag concrete

A technology of concrete and copper slag, which is applied in the field of preparation of shrinkage-reducing copper slag concrete, can solve the problems that hinder the application of copper slag powder, complex influence on workability, mechanical properties and durability, and high content of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

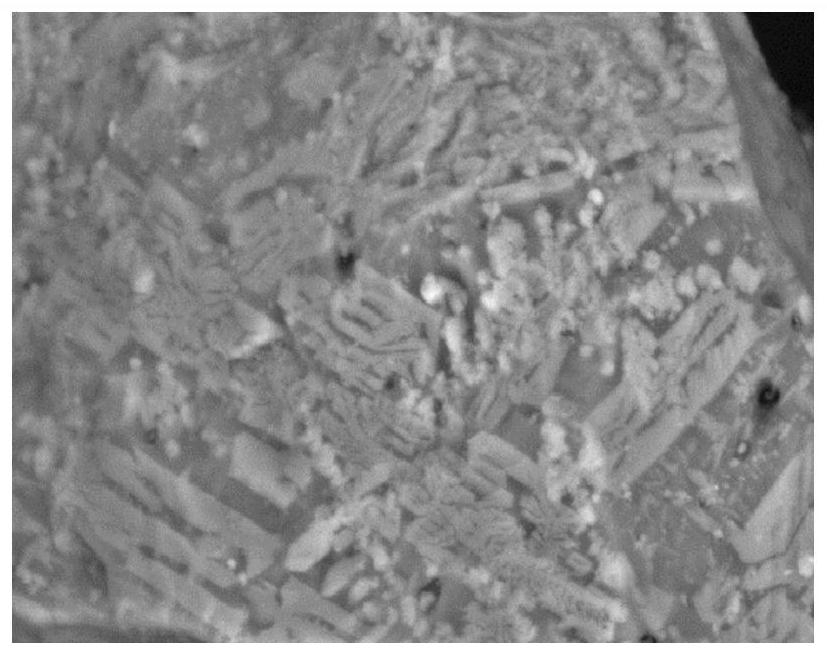

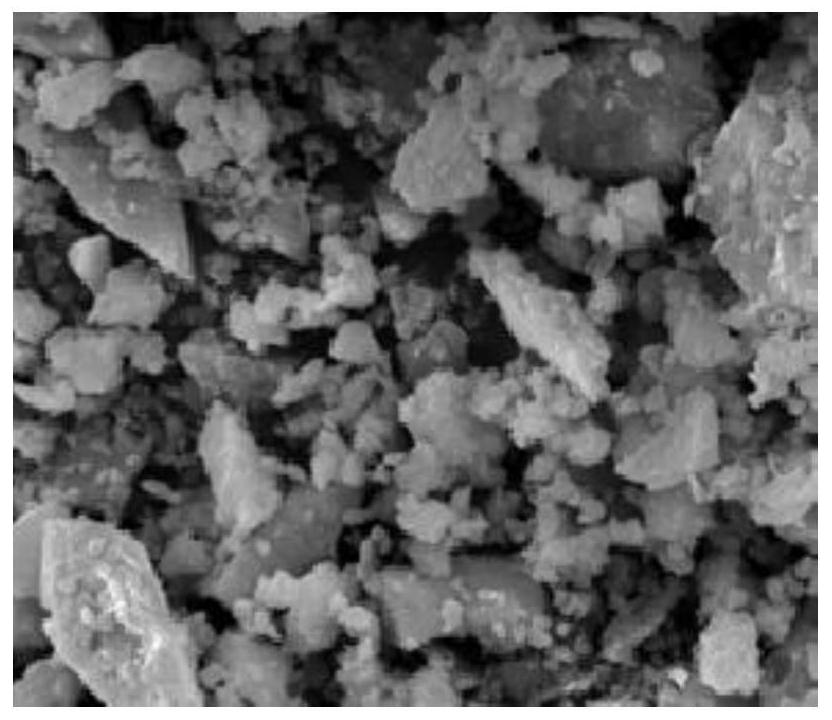

[0022] refer to Figure 1 ~ Figure 2 As shown, the preparation method of the shrinkage-reducing copper slag concrete in an embodiment provided by the invention may further comprise the steps:

[0023] Step 1, activating copper slag by high-temperature calcination;

[0024] Step 2, the copper slag is subjected to ultra-fine airflow grinding to form copper slag powder;

[0025] Step 3, using copper slag powder as raw material to prepare concrete.

[0026] Further, in the above step 1, the specific process of calcination and activation of the copper slag at high temperature is: calcining the copper slag in a furnace at 950-1000°C for 30 minutes, cooling the copper slag in water after calcination, and then drying it to a constant weight .

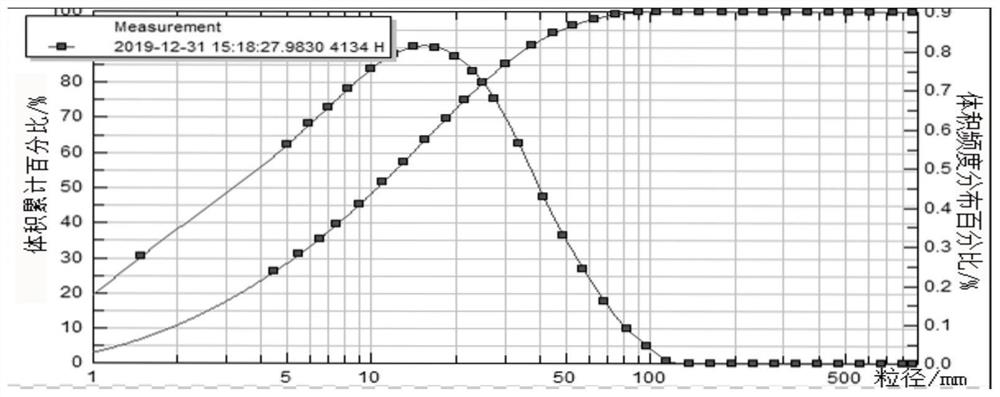

[0027] Further, in said step 2, the specific process of ultrafine airflow grinding of copper slag is as follows:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com